Featured on

CAMARO5 HOMEPAGE.

If you're not aware who Eric Berry is, pretty much all you need to know is the guy's a monster on the football field. He played for the University of Tennessee, where he did well enough for himself that he grabbed the attention of many NFL teams...

Just recently, Eric was signed by the Kansas City Chiefs...

With his $60,000,000/six year contract signing, Eric had quite a few options of cars to go with. Which did he choose? Not a Lamborghini, not a Ferrari, not a Bugatti, not a Koenigsegg. He put it bluntly; "I'm a Chevy guy." He wanted a National Speed NZ1200 Camaro. While the NZ1200 is a pre existing concept, this particular model is the NZ1200-EB Edition. The EB Edition will feature various differences (i.e. paint schemes, wheels, performance differences, etc.), and is special in the sense that for this and each future NZ1200-EB sold, National Speed will donate $10,000 to the Eric Berry Foundation. While the car is technically an NZ1200-EB Edition, it is still built off the NZ1200 platform. What is the NZ1200 platform? To the point; 427ci (7.0 liter) engine, twin-turbocharged, 1,200hp on pump gas, bullet proof drivetrain, world-class handling suspension (capable of 1.3gs on the skidpad), full braking upgrades, etc. The theory is to upgrade all performance aspects proportionally, and over engineer everything. This vehicle would be capable of sustaining 2,000hp+ without issue, that's how over engineered this vehicle is. The result is a bullet proof performance package that is OEM-like reliable and drivable at this level.

After months and months of anxiously awaiting the customized components for this build (many of which did not exist until literally last week), this build is ready to hit hard and get done.

On with the documentation thus far;

Step one was to find Eric’s 2010 Chevrolet Camaro SS. We located a great deal from Jeff Gordon Chevrolet in Wilmington, NC, and snapped it up. Purchased with 12 miles on it.

First time out front of National Speed, getting looked over by employees and customers that were there at the time…

I love the front end of these cars…

Soon to be drastically changed…

In the shop for the first time…

Crawford getting the vehicle disassembled to start rolling forward…

Bumper support fabricated so the carbon fiber components can be fabricated…

(this essentially retains the bumpers shape so an accurate mold can be made)

(the pictures below are the parts included in the build, but not limited to)

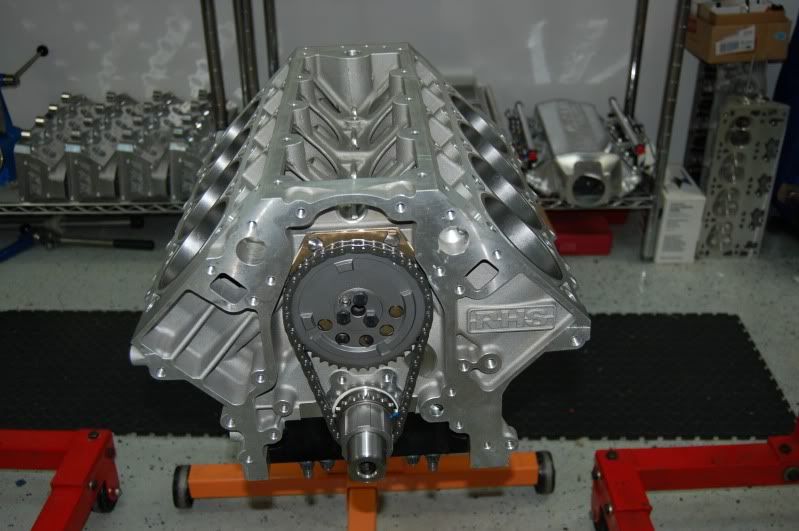

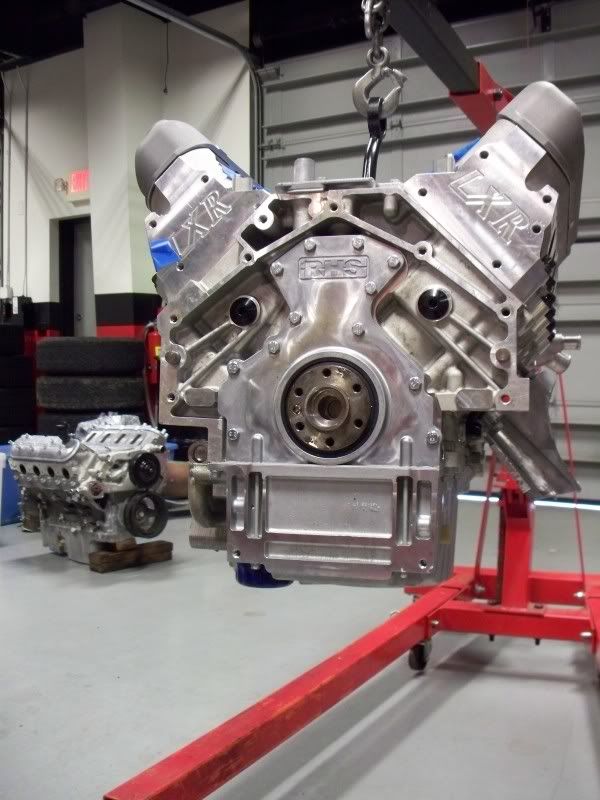

The engine assembly under way…

Gorgeous…

The engine in the crate, awaiting assembly…

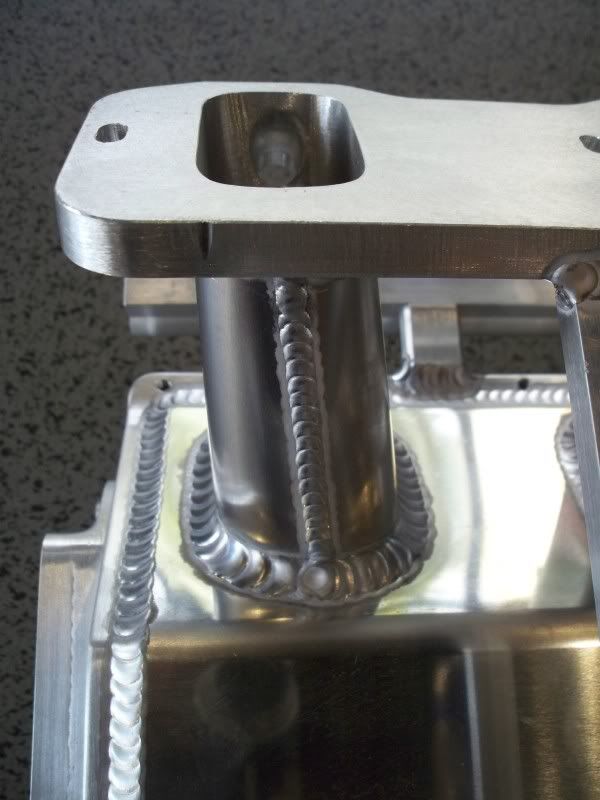

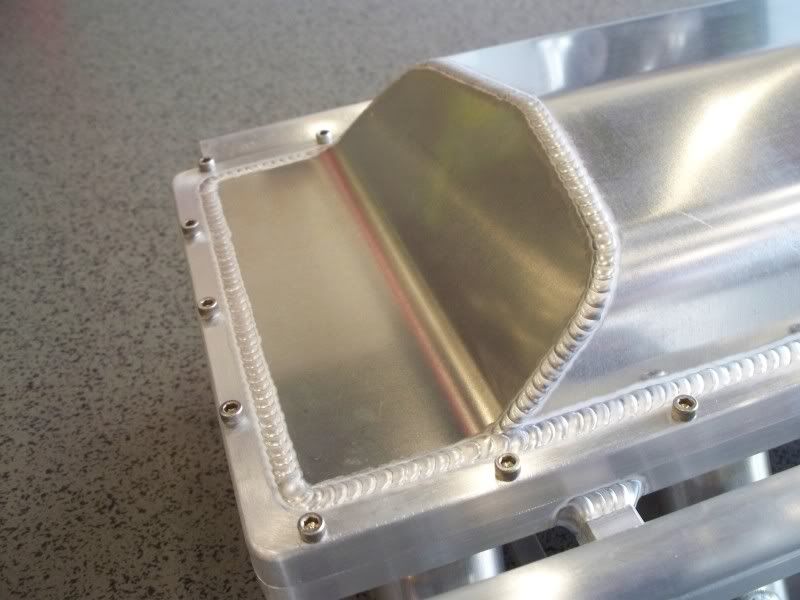

The custom made John Marcella intake manifold…

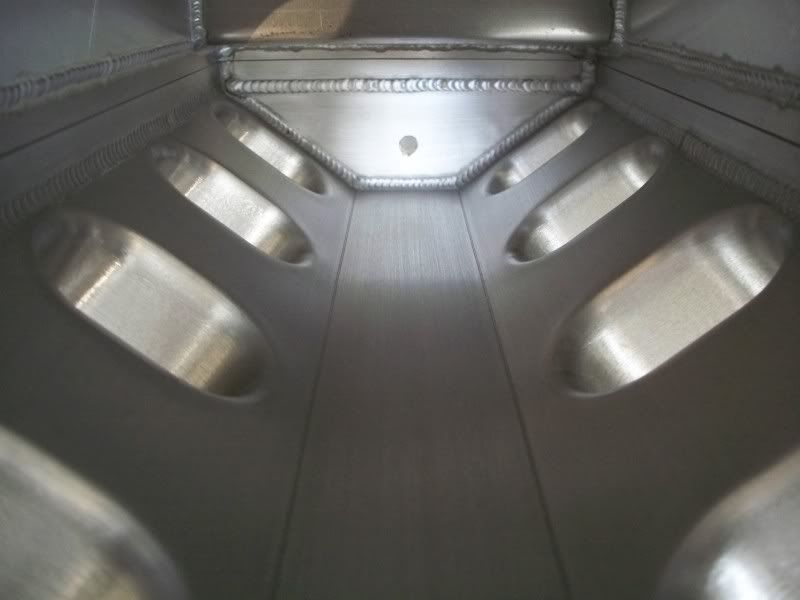

The belly…

Underside of intake runner…

Internal shot…

A few shots of the weld quality…

Rossler Terminator-IV 4L80E transmission…

The Strange Engineering nodular iron third member with options…

Cover removed…

Beautiful…

Hendrix Engineering 9.00” rear-end (this is one of those components that didn’t exist until last week, special thanks to Thomas Hendrix for coming through for us on this, and personally delivering it to National Speed. He’s a great guy);

Installation components, still wrapped…

The housing…

300M axles…

Full Pedders Track-II Xa “Justice” suspension system (only the coilovers are picture below), only the best Zeta suspension system in the world for this car…

Brembo GT front and rear brakes…

Gigantic brake rotor…

Rotor and caliper side-by-side…

In comparison to my size 13…

Rear suspension, drive-train and fuel tank coming down. John and Crawford hard at it...

Ben up front working on the inter-cooler design...

Ben working on the design...

Rear sub-frame removed...

Fuel tank on the way out...

You've got to love brand new cars, absolutely spotless...

Fuel tank removed, packaged and ready to head out for the modifications required to support the huge fueling requirements of this setup...

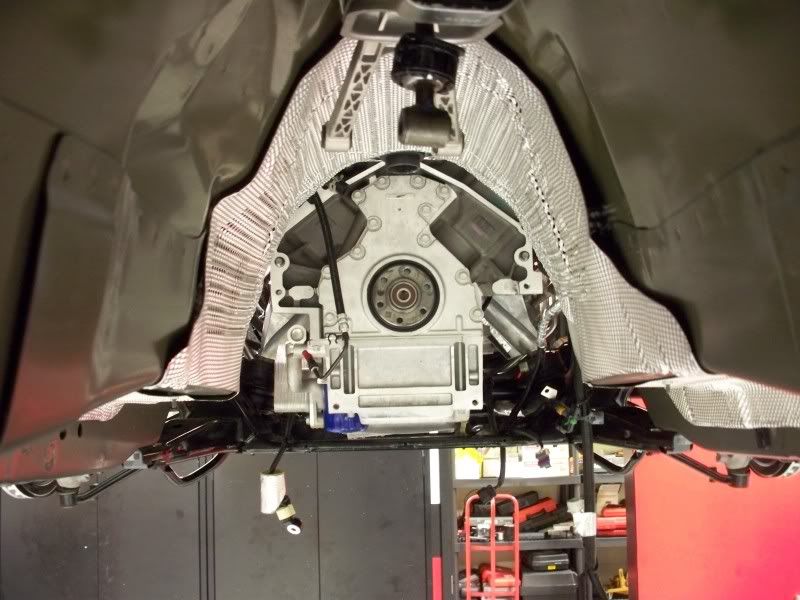

TR6060 transmission removed, engine up next...

Spotless LS3... A thing of beauty...

The engine on its way out...

Stripped down...

"On the up and up..."

Coming out...

“The weak ones are there to justify the strong...”

RHS...

Performance Inductions...

Front view...

The 427 going in...

In place...

Crawford getting the suspension started...

Stock front sway bar removed...

Clearancing the frame rails for the 4L80E transmission...

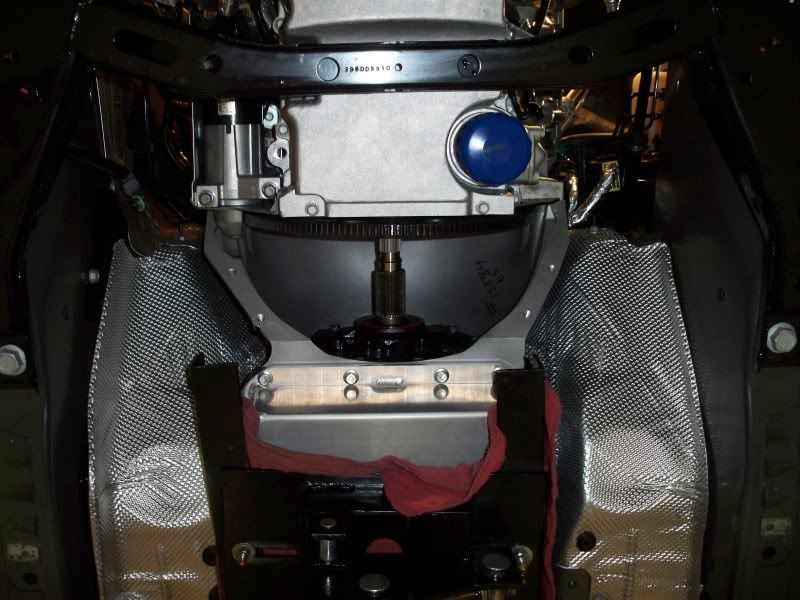

Rossler Terminator-IV 4L80E...

Crawford getting ready to fit the 4L80E transmission to fabricate the cross-member...

(no, that's not the engine's ora, it's one of the spotlights from above, haha)

This picture came out really strange looking, worth sharing, haha...

The car, as it sits now...

Play-by-play of Crawford putting the transmission up...

The fitment is perfect, obviously no torque converter in place quite yet...

Further fitting...

The Pro Torque torque converter came in today...

Notice anything different here? That's right, it's a six pad billet plate, as opposed to the standard three pad. Another full custom "doesn't exist" unit...

The Marcella intake manifold mocked in place...

The intake manifold to cowl clearance...

Crawford test fitting the 102mm billet aluminum Nick Williams throttle body. Another "doesn't exist" component when ordered...

Intercooler core in place for test fitting...

The OEM GM automatic conversion components came in;

- Steering wheel and paddle shift components

- Brake pedal assembly

- Shifter assembly and components

Paddle shift components in place...

Shifter assembly...

Brake pedal assembly...

BMR trailing and toe arms...

The Pedders bushings ready to go in...

The shifter assembly will bolt directly in without modification to the tunnel, great news...

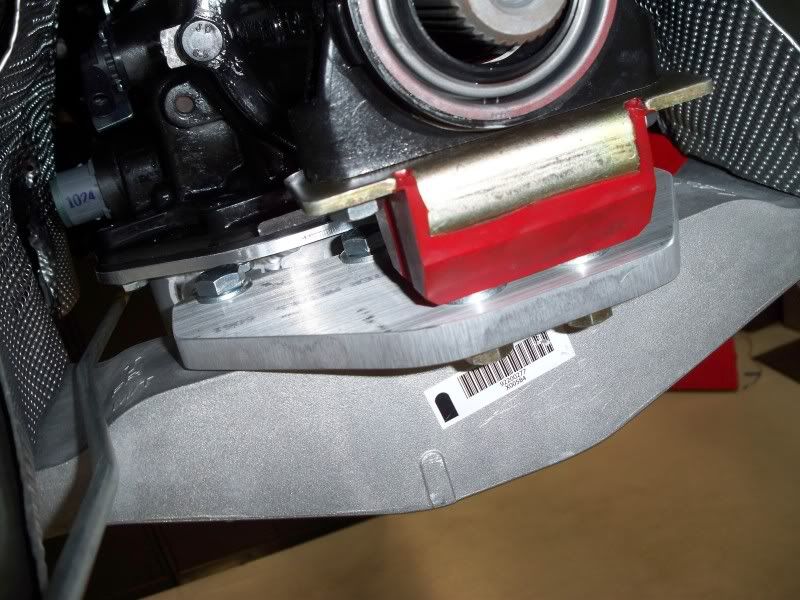

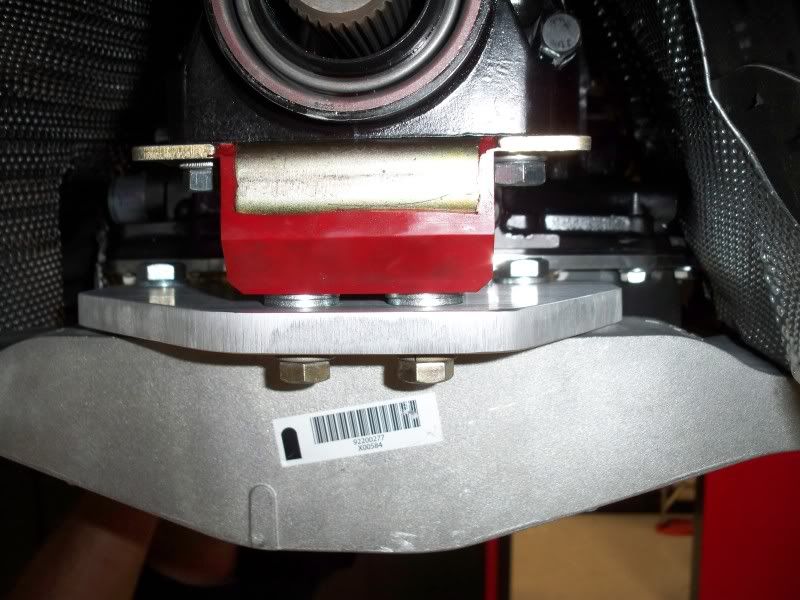

The 4L80E to manual Zeta adapter bracket Crawford fabricated...

The transmission pan can still be accessed and dropped like stock...

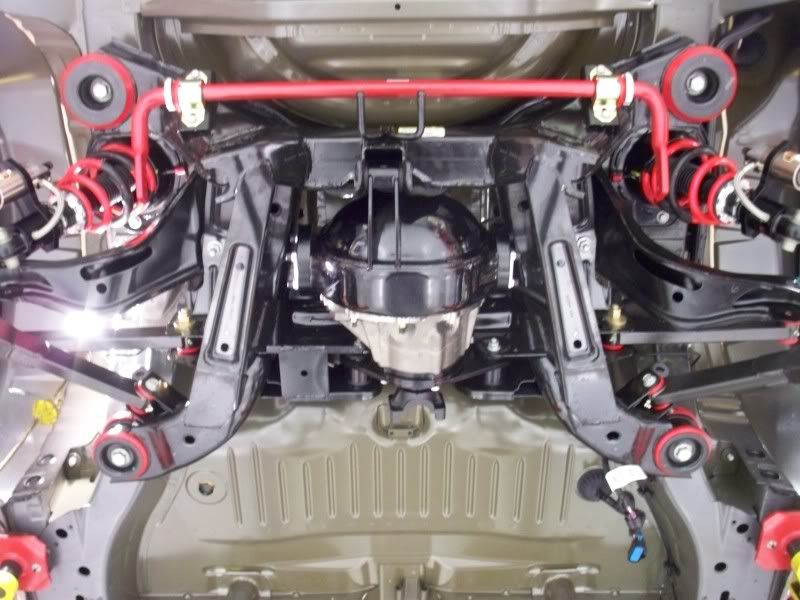

The rear subframe fitted with Pedders bushings, sway bar and BMR trailing/toe arms...

The rear subframe reinstalled for the time being (i.e. until the fuel tank arrives back), Pedders in place in the rear. Absolutely PERFECT fitment and finish from Pedders as always, I love Pedders for that;

From the rear...

Rear diagonal...

From the front...

Xa coilovers in place...

The Strange Engineerning nodular iron third member in the Hendrix Engineering 9.00" housing...

The Hendrix Engineering 9.00" housing in place. Beautiful fitment as expected...

The Brembos going on...

The turbochargers showed up today, Ben and Chris are now ready to start killing the turbocharger system fabrication...

Profile...

V-band inlet and outlet turbine housings...

Air-cooled dual ball bearing CHRAs...

Billet compressor wheels...

"OMG IT SPINS!!!"

The evil twins...

The belly of the beast (i.e. John Marcella intake manifold)...

Injector Dynamics ID1000 high-impedance 1,000cc injectors in place...

(this picture turned out cool, I just wanted to share, haha)

Fabrication masters Ben Salasko (our in-house tuner) and Chris Polanski (our company President) working on the turbocharger system fabrication...

The fuel tank arrived back from Lonnies Performance today, he turned this around QUICK, a pleasure to deal with as always...

(apologies, I took four pictures of this, and they all came out blurry... Damn camera)

The fuel tank reinstalled...

Crawford and Ben Salasko getting the rear subframe and suspension back in place...

The stock wheels in comparison to the Brembo brakes...

The car getting back to a rolling state...

The new intercooler core mocked up in place...

The car down for the first time on the new suspension/braking system...

The ride height's still around .75"-1.00" too tall in the rear, once it comes down to where it should be, you can see how perfect the suspension geometry will be (i.e. the relation of the rear-lower control arm's angle to the ground)...

Today Chris and Ben got some excellent progress made on the turbocharger system. Unfortunately, I didn't get over to start documenting until later in the day, so I missed a bit of it.

Chris welding up the cold-side charge piping...

Test fitting...

What we're going for here; perfect symmetry...

Perfect charge routing...

(no, the existing end tank is not be used, we are building a new one)

Chris welding up the second TiAL 50mm blow-off valve flange...

Test fitting... Absolutely perfect...

With the flash on to show the detail of the welds a bit better...

Side-to-side...

Ben started on the exhaust portion of the turbocharger system today, and made some great progress. Just to let you know who Ben Salasko is, he's an absolute mad man with anything to do with fabrication or wiring/tuning.

This is a sample of his welding skills on his S2000's 4.00" exhaust...

Oh yes, NZ1200 is in for a treat.

The turbocharger connector pipe tacked in place...

Turbocharger fitting...

Ben laying the final welds...

Coming along great...

Rotating view...

Turbocharger mounted...

Chris got rolling on the intercooler cold-side end tank fabrication as well;

Old end tank removed...

Taping up the passages...

Milling the mating surface perfectly flat...

"X" marks the spot...

New end tank design theory...

Looking good...

Ben working on the exhaust system, he's also got the TiAL MV-S wastegate in place on the driver side...

The cold-side end tank fabricated, ready for finalization...

The passenger-side turbocharger connector pipe fabricated...

The OEM center support bar cleanly removed...

Oh... Why look at that...

It looks like the bar was never there...

Underside view of the bar removed...

In case anyone is wondering, the bar was not just removed without a replacement in the works. We are building a new crossbar that has charge piping incorporated in a bulkhead manner. So we essentially retain the structural integrity, while allowing for direct charge routing, pretty awesome.

National Speed is a Pedders Dealer in Wilmington, NC. I want to complement them on a fantastic build. A Supercar by National Speed with Pedders Supercar Coilovers for soon to be Super Star at Safety for the Kansas City Chiefs! We wish him all the best with the Chiefs, unless he is playing d'BEARS where he will be the defenssive star for the Chiefs but the offense will turn the ball over 14 imes leading to a BEARS victory.

UPDATE

The passenger side turbocharger connector pipe finalized...

The driver side turbocharger connector pipe almost finalized, the wastegate pipe coming together...

Ben mocking it up...

Ben finalizing the driver side pipe...

Buzz...

BUZZ...

A sample of Ben's final welds on the connector pipe...

View from inlet to outlet...

Almost completed...

Finalized...

The turbochargers in place;

With flash to show detail...

Without flash...

Driver side...

Passenger side...

The new subframe crossbar fabricated, with intake passage tubes in place...

Taking shape...

Perfect...

The hot-side intercooler end tank completed...

The intake system coming together. The routing;

Front to rear view...

Rear to front view...

Chris getting the driver-side intake tube together...

The compressor wheel view through the intake tube...

The hot-side charge routing being fabricated...

(look behind the intake tube)

Where it's exiting out the front of the crossmember...

The compressor cover outlets cut off, and ported...

New outlet elbow port matched and ready to be welded on...

Chris welding the elbow up...

Turbocharger intakes and subframe removed so I could get a better shot of the hot-side charge pipes...

The passenger side...

Driver side...

The hot-side end tank of the intercooler nearing completion...

Rear to front view of the turbochargers in place, with downpipes. The dumptubes are completed, but are uninstalled at the moment...

Torque converter dust shield, sides left open for cooling...

And I realized I never did post a picture of the Hendrix Engineering 9.00" rear end installed with the axles;

Nice and clean, like stock...

The aluminum air directors in place, these panels will keep the air movement directed in essential focused locations...

The new radiator support brackets...

Chris fitting the intercooler...

Beautiful...

The modified subframe finalized, it looks OEM...

The car moved out of the fabrication bay back into Crawford's bay for finalization...

The Hendrix Engineering 9.00” housing, axles and driveshaft in place. Once again, I cannot stress enough the quality of these components, the fitment is perfect…

Also, in case anyone is curious as to why we chose to use the factory manifolds instead of tubular manifolds, read below;

This was a topic taken under heavy consideration in the design phases of the build, we made a conscious decision to progress in the direction we chose.

We looked at designing and fabricating tubular turbocharger manifolds (our technicians are obviously proficient to properly complete the task). However, after looking at the path the runners would have to take in order to accommodate the accessories and engine bay constraints, we essentially would have ended up with log-style tubular manifolds. No reason to do so, when we have perfect log-style cast manifolds in place already.

A large portion of our logic was that the factory cast manifolds are proven to be resilient and durable to heat cycles. Structural integrity with turbocharger manifolds is obviously of extreme importance, especially at the EMAP levels that will be present on the 1,200hp setting. Since the target horsepower will easily be achieved with this design, we decided applying the KISS (Keep It Simple, Stupid) method was the best policy.

Many setups have achieved 7-second passes on the OEM cast manifold turbocharger system design. They will support our power level requirements with ease.