The idea The years-long process of taking a car from a designer's idea to final production is expensive, time-consuming and loaded with potholes.

The story of General Motors' Chevrolet Camaro from a pen-and-ink drawing to a concept car to near-production shows how this process shapes every car we drive.

The sketch at the right, made in the Summer of 2005, shows early thoughts on how the car was to look.

Some elements, like the shape of the taillamps, made it into the concept vehicle, which was unveiled only months after this sketch was made, and continued on into the production car. Other elements, like the stretched-out rear window pillars and the front fender vents, didn't make it onto the finished car.

Once the sketch was approved by GM executives, 3/8 scale models were made, followed by full-sized clay versions.

In this picture, taken in the second half of 2005, General Motors' head of global design, Ed Welburn, closes the door on his 1969 Camaro as it stands near a clay model of the Camaro concept car.

The clay model is finished in what a designer call a "clown suit." Using clay and a colored film called Di-Noc, one side of the model is formed to one design idea and the other half another.

A mirror, cut to fit the profile of the model, can be placed over the center of model creating a complete image of each of the two designs.

GM designers and executives ultimately decided to pursue the design shown on the car's left side.

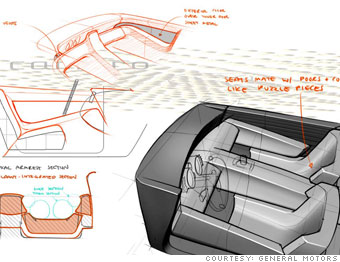

By this time, final sketches were also being made of the Camaro concept's interior. In these sketches, designers work out seating positions as well as the locations of instruments and controls.

Since these sketches were only for a concept vehicle, designers were freer to create an interior that might not have been ideal for every body shape. For the final production version of the Camaro, changes have been made to the seats to allow greater comfort for taller drivers.

Computer-controlled carving tools helped designers shape clay layered on top of a foam form. By now, in Autumn 2005, a near-final form for the Camaro concept car had been decided on.

Full-scale models can reveal details or subtle proportions that need more work. Clay is used because it can be quickly reshaped without having to rebuild the model.

Just as exterior designers use life-sized clay models to get a sense of shape and forms, interior designers use detailed clay mock-ups as well.

Coatings that mimic materials, including leather, metal and wood, are laid over a model like this to give a very real sense of what the interior will ultimately look like.

With all the coatings and colors in place, the final interior model looks very much like what was ultimately shown at the Detroit Auto Show in January of 2006.

Working with molds made from the final approved clay models, GM craftsmen began forming and assembling the fiberglass parts that would make up the Camaro concept car that was shown in Detroit.

The interior was also molded in fiberglass. In this image, Anne Asensio, lead interior designer for the Camaro concept, looks over the unpainted dashboard.

GM did not grant final approval for a production version of the car until after it was revealed at the Detroit auto show. But designers have tried to maintain, as much as possible, the concept's interior look, the company has said.

General Motors has promised that the production version of the Chevy Camaro will closely resemble the concept car in this photo from January 2006. Some changes have had to be made for the sake of practicality and performance.

Slight changes have been made to the front end to improve airflow to the engine. The vents in front of the rear fender have been replaced with cosmetic indentations, and the side-view mirrors are larger.

The production car will also have a thicker "b pillar," which is the post between the front and back windows.

In August of 2006, with approval for a production version in hand, a large team of GM designers and engineers began working on the project.

The concept car was, basically, all design with practically no real engineering. It had a top speed of 40 miles per hour, no ventilation, no side windows and, of course, no consideration given to occupant safety.

The Camaro was not going to be based on any existing GM "vehicle architecture." GM turned to the rear-wheel-drive experts at the company's Australian Holden division to begin the engineering that would underlie the Camaro.

Engineers and designers began assembling the computer code that describes each part inside and outside the car. Computer models of the car were put through digital wind-tunnel tests and crash tests before the first hand-built test cars were even created.

Several largely hand-built test vehicles, costing about $250,000 each, were constructed in Australia. These cars were used for for driving tests, crash tests and extreme weather endurance testing.

Portions of the cars were sent to the Canadian factory at which the production Camaros will ultimately be built. There, factory workers looked over the vehicle sections, pointing out areas that will be difficult to assemble or hard to reach. Cars that are easy to assemble on the production line are less likely to have quality issues later.

The test cars were also camouflaged with paint and tape to hide their true shape from prying photographers.

Because cars are subjected to a variety of extreme conditions, automakers test them in the harshest environments around. GM does its cold-weather testing in Kapuskasing, Ontario, Canada.

The cars are expected to start in temperatures as cold as 40 degrees below zero. If the Ontario winter turns unseasonably warm, the cars can be placed in garage-sized freezers.

Tests including dousing the cars in water and letting them sit in the freezing cold overnight then trying to get them open in the morning.

Hot weather testing takes place in Arizona and Australia. The cars, and their occupants, are subjected to temperatures above 120 degrees. The cars' air cooling, air conditioning and ventilation systems are expected to perform well in this situations.

Cooling systems must prevent overheating, even under heavy loads, and the air conditioner is expected to take the car from blistering to breathable in a matter of seconds.

In January of 2008, GM announced the cars would no longer be camouflaged, as these are, during testing.

Full-scale production of the Camaro is still a year away, at least, as the cars go through continued testing and validation.

http://money.cnn.com/galleries/2008/...ent/index.html

It's a 13 page photographic piece detailing the Camaro development from the first sketches in 2005 until today. There's a couple of previously unseen photos in there too. It's pretty cool