You are browsing camaro5

|

|

|

#1 |

Drives: 2012 2SS/RS LS3 Join Date: Dec 2011

Location: Omaha, Nebraska

Posts: 1,677

|

Catch Can question w/ procharger

So I am running a draft can style can from Mighty Mouse on my F1A setup with PVC deleted. Basically its one -12 AN from the oil fill adapter to the can and then a -6 AN line from the can to the filter on my procharger. My question is what are people using for fittings on the filter side? Do I just find a male threaded push fit -6 fitting or what is everyone else using?

__________________

2012 2SS M6, ERL Superdeck 6 427, PRC 255 Heads, Procharger F1A w/ 3.85 pulley, 1300hp intercooler, Squash Dual 450lph, E85, ID1700, RXT Clutch, DSS 1pc driveshaft, GForce axles, Eaton Detroit Trutrac, a bunch of other crap I don't feel like typing.

|

|

|

|

|

|

#2 |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,382

|

So you're aware, by using a vented Catch Can you only evacuate (remove/suck out) the damaging compounds that are constantly entering your crankcase at idle and deceleration as any other time there is no vacuum present to evacuate.

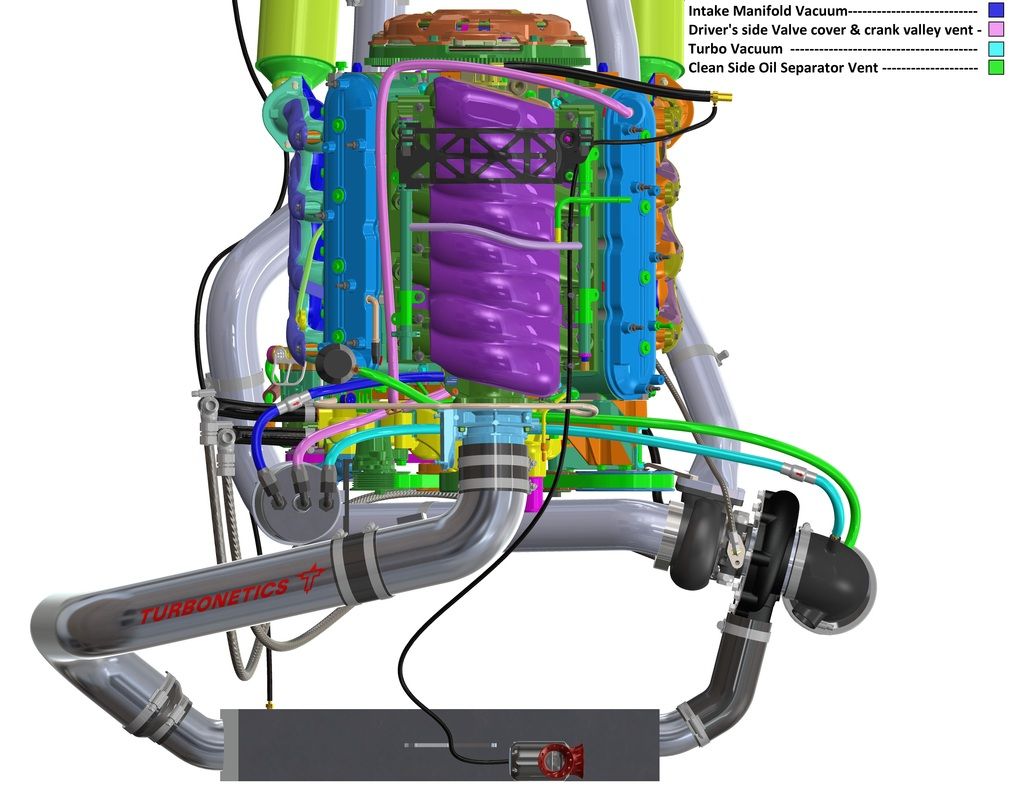

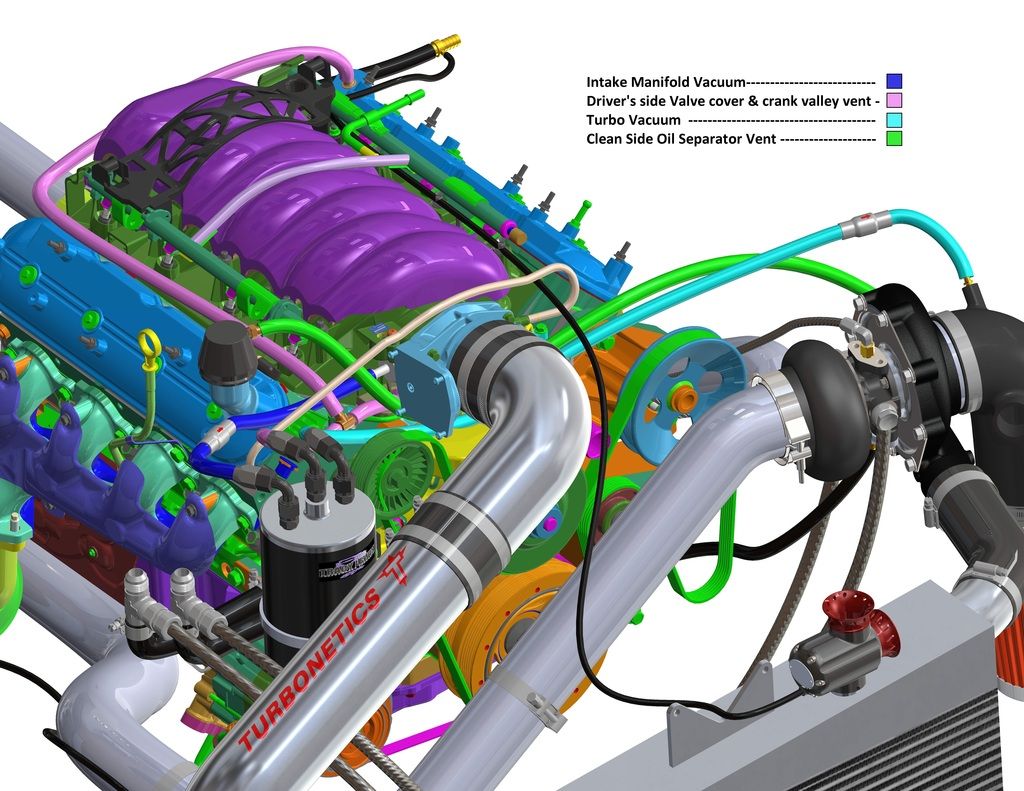

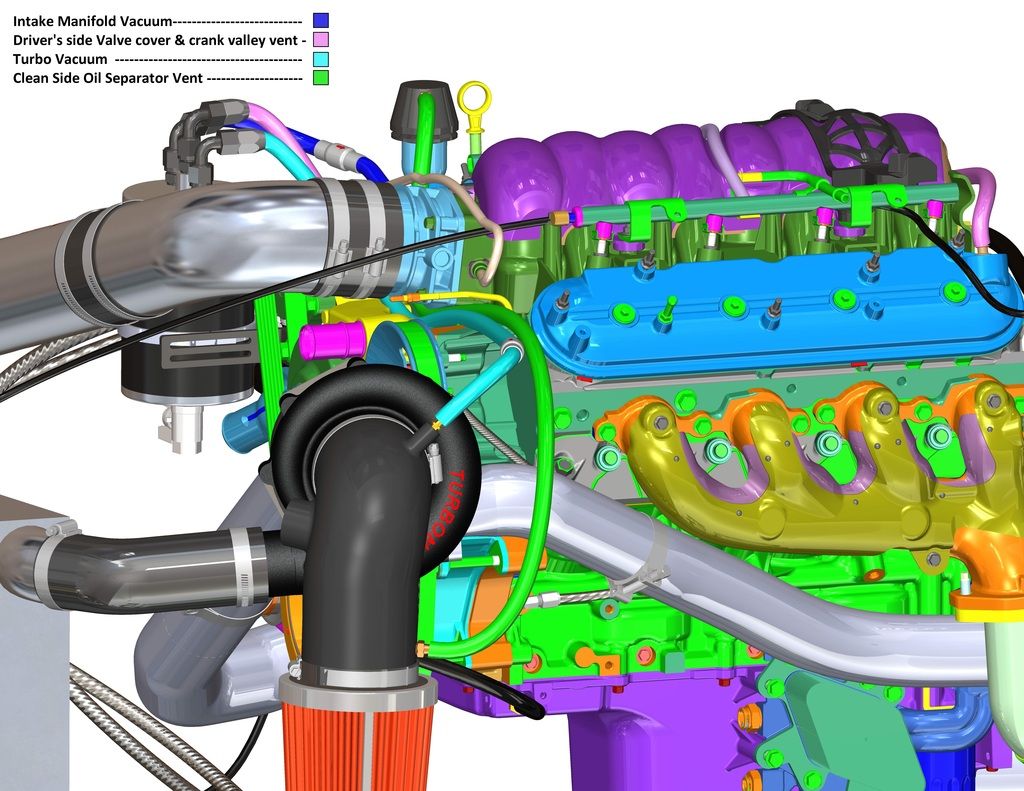

This allows most all of these compounds to settle and accumulate in your crankcase and engine oil. The other issue is ring flutter that increases blow-by and produces less power and over time wears "divots" or chatter marks into the cylinder walls. These engines are built with low tension piston rings that require suction below and pressure above to maintain proper seal and stability. To avoid these issue use a proper system that pulls full time evacuation on the crankcase helping maintain ring stability as well as keep the contaminating compounds out of the oil and crankcase. Up to 1200 HP forced induction our system has been tested and proven by Turbonetics head of engineering on their in-house big boost builds as these illustrations they provide show:    You can see our E2-X Ultra used here in their illustrations provides full time evacuation and suction on the crankcase never allow pressure to build in the first place. It also comes with the billet cleanside separator unit addressing the incoming filtered fresh air that flushes and replaces the foul contaminate laden vapors being sucked out the opposite bank. So nothing to vent into the engine compartment. It also provides unrestricted release of pressure should you develop a breach in the piston/rings/cylinder wall seal and no danger of ever having pressure present. And as the most effective separation design on the market, it traps 95-98% of all the compounds that enter it only allowing scrubbed intake air charge. You can choose -8 or -10 fittings for these and they come with dual billet checkvalves. Let us know if you would like more information. As all Professional Motorsports dropped "venting" decades ago due to the issue listed above, to see people with their investments doing this now leaves us puzzled as to why. But there are proper solutions available from others and not just us if you wish to do this properly.  |

|

|

|

|

|

#3 |

Drives: 2011 Camaro SS 6sp Join Date: Nov 2016

Location: Drivers Seat

Posts: 1,904

|

Quote:

This is great to info. As someone who just recently bought a SC kit, I was concerned if the current catch can I'm running will be compatible. Is the E2X-Ultra the only can you offer for FI apps? Can I use my simple two port can on my FI application?

__________________

2011 Camaro SS---SOLD

TMS Dart 427 FED M311s, ESS Tuning G4 Blower, DSX Triple FP Assembly, DSX FF, FIC1300, Mcleod RXT 1200HD, Edlebrock Pro Flo XT 1158whp 1017wtq. 2010 CTS-V A6 - "Stock" SOLD 630whp 658wtq 2024 F-150 RCSB 5.0 4x4 waiting for tunes... |

|

|

|

|

|

#4 |

Drives: 2014 SS 1LE Join Date: Apr 2014

Location: United States

Posts: 660

|

Depending on the material that you are trying to penetrate on the filter (i imagine it is plastic or rubber), i have seen some guys use an AN fitting. Drill a hole just big enough to get the nipple through the backside (but so that the flange cant get through the hole) and let the push on hose secure it. Or a fitting with a bolt on the back.

https://drive.google.com/drive/folde...V9LN2M1Q0IyUGs There is a picture in the middle of that page with an example. Why does Elite keep using the same copy and paste post for every catch can topic? They didn't even answer the guys question lol.

__________________

|

|

|

|

|

|

#5 | |

Drives: 2012 2SS/RS LS3 Join Date: Dec 2011

Location: Omaha, Nebraska

Posts: 1,677

|

Quote:

Thanks, I think I might be able to re-purpose a fitting that procharger sent in the PVC bag.

__________________

2012 2SS M6, ERL Superdeck 6 427, PRC 255 Heads, Procharger F1A w/ 3.85 pulley, 1300hp intercooler, Squash Dual 450lph, E85, ID1700, RXT Clutch, DSS 1pc driveshaft, GForce axles, Eaton Detroit Trutrac, a bunch of other crap I don't feel like typing.

|

|

|

|

|

|

|

#6 |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,382

|

Bildo,

You can simply press it into the coupler as there is no pressure on the air filter to push it out. Us some RTV then to neatly secure it. eLeSthree, For less than 8# of boost the standard E2-X can be used. jeff657756 Let's have a detailed technical discussion on this topic? The OP has made a choice that will lead to excessive wear and shorten engine life the way it's described. All evacuation is defeated in the way it is described except at idle or deceleration. Nothing good can come from doing something like this and tons of data from the Professional racing industry on this and more. We're just trying to educate. Obviously it's their choice, we're just trying to put some educational information out there. But lets have a discussion on the technical aspects of both approaches as it appears you seem to like harming an engine over time? Cheers! |

|

|

|

|

|

#7 |

Drives: 2012 2SS/RS LS3 Join Date: Dec 2011

Location: Omaha, Nebraska

Posts: 1,677

|

I have no PVC, no connection available to my intake, don't see any other options.

__________________

2012 2SS M6, ERL Superdeck 6 427, PRC 255 Heads, Procharger F1A w/ 3.85 pulley, 1300hp intercooler, Squash Dual 450lph, E85, ID1700, RXT Clutch, DSS 1pc driveshaft, GForce axles, Eaton Detroit Trutrac, a bunch of other crap I don't feel like typing.

|

|

|

|

|

|

#8 | |

Drives: 2014 SS 1LE Join Date: Apr 2014

Location: United States

Posts: 660

|

Quote:

I am genuinely interested in how your can uses "turbo vacuum" to get crank pressure out under boost. That would mean the turbo filter flow has to be so poor that it creates enough vacuum to accomplish that. Wouldn't that defeat the purpose of a power adder? Who actually uses that can (the one in the same generic CAD drawing you guys keep posting) on high hp / boost builds? Any on the fast list? Any real world examples besides the "turbonetics head of engineering"? We get it, your cans catch oil for the cai/ headers guys who like a pretty shiny piece under the hood, but what about guys worried about crankcase pressure? You think those guys care about premature engine wear? Cmon man lol. It's like a robot is running that account. You are so full of your product that you dont even pay attention to the post that you are commenting on. You guys bash anything that's not elite which is why i and am sure plenty of other high hp guys will NEVER run one of your cans.

__________________

Last edited by jeff657756; 01-25-2018 at 02:22 PM. |

|

|

|

|

|

|

#9 | |

Drives: All things Turbocharged Join Date: Dec 2010

Location: AZ

Posts: 1,199

|

Quote:

Now you stop using logic, we'll have none of that here. |

|

|

|

|

|

|

#10 | |

Drives: 2011 Camaro 2SS/RS Join Date: Oct 2011

Location: Texas RGV

Posts: 794

|

Quote:

|

|

|

|

|

|

|

#11 |

Drives: 2011 2SS Synergy Green Join Date: Nov 2011

Location: Austin, Texas

Posts: 3,670

|

I have a MM can on my Maggie's L99 and it doesn't catch oil at all. Dave tried to help me out but his can does not work on my car. When I drain it all I have is moisture/condensation and oil in my supercharger inlet.

I do have an extra Elite Engineering can (The basic one) but I emailed them to ask for directions on hose routing and I never got a reply so it sits on a shelf.

__________________

L99 With a Maggie

|

|

|

|

|

|

#12 |

Drives: 2012 2SS/RS LS3 Join Date: Dec 2011

Location: Omaha, Nebraska

Posts: 1,677

|

I had a fast 102mm but it broke putting the two shells together I still have not mailed it back in for the RMA I got. I bought a Holley Sniper low pro as a cheap fix, should have bought something better, but you get what you pay for, they screwed up and sent me 2 for the price of one so I ended up getting it for free. I am at the point of getting it running and everything broke in, a custom intake will be in the works with a F1X in the future. The build minus the factory M6 and the slightly built rear end should handle 1200+. Thinking a frankenstein type combo of a vic and an elbow welded and ported......

__________________

2012 2SS M6, ERL Superdeck 6 427, PRC 255 Heads, Procharger F1A w/ 3.85 pulley, 1300hp intercooler, Squash Dual 450lph, E85, ID1700, RXT Clutch, DSS 1pc driveshaft, GForce axles, Eaton Detroit Trutrac, a bunch of other crap I don't feel like typing.

|

|

|

|

|

|

#13 | |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,382

|

Quote:

First, we explain in great detail on each of these posts how we prevent pressure from building in the first place. And we generally point out, but itís often ignored, that "venting" went out of favor decades ago in ALL forms of Professional racing. Because this conversation and comparison started with the MM Catch Can, letís start there. First, the MM uses only the intake manifold for evacuation suction. It then relies on pressure building and venting out the breather, correct? So, with a turbo or centrifugal supercharger, the ONLY time evacuation takes place (evacuation if you look up the definition is actual pulling suction on an area, it is not releasing pressure). Then combine that with the MM, thatís only able to separate and trap approx. 50% or so of what enters it and you still have ingestion issues (may not be oil covering intake, but plenty is present) vs the 95% plus effectiveness of our design. We use Intake Manifold vacuum when present for evacuation, and the turbo or centrifugal inlet does NOT provide vacuum by restricting the air filter, it generates this via the Venturi Effect of airflow past a barb located right at the head unit inlet at the proper angle (google "Venturi Effect" to understand how this principle works). This can generate up to a steady 14-16" of vacuum, but we typically see 2-4" when measured. Still more than enough to never allow pressure to build in the first place. So, no matter what mode your operating in, boost or not, the system ALWAYS pulls suction on the crankcase. Then as we are a complete system (And AGP Turbo, here is where we would like you to pay attention), we also include our billet cleanside separator, or CSS. This replaces the oil fill cap and adds an additional guard against any oil mist entering if there is a brief period where pressure could build, it adds 3-4" plus of vertical height as well as a separation chamber internally with coalescing media in it that traps any oil during a momentary pressure spike. So, if you compare the 2 side by side you see the differences:  We use -8 AN fittings standard, and -10 as an option. The CSS connects to the main air filter and provides the filtered clean fresh air that flushes and replaces the foul contaminant laden vapors exiting the opposite portion of the crankcase. If there would be an issue with pressure (and we have thousands of these systems in use with 1000 plus HP single and twin turbo's as well as centrifugal SC builds) it simply releases through the CSS into the main air filter so no fumes get into the engine compartment. This also meets emissions guidelines for retaining a close system. As we trap the oil mist and other compounds oil is not ingested. Look at how a 1200 HP twin turbo LS build is configured, and all you have to do is ask any of these people how well it works (many had first used the MM Catch Can and were resistant to considering this, but would never go back after actually experiencing our proper system): You will note the Venturi fittings should be closer to the turbo inlets than in this example. Letís take this one step at a time so you can then go to the next technical aspect. Thanks again, and AGP, you guys do a real quality offering, you have nothing to lose to actually understand how this works, and if it did not work as we claim, you can bet these people would be telling the World instead of using nothing but going forward. Again, benefits over MM: We provide full time constant suction on the crankcase preventing pressure form ever building in the first place. We trap approx. twice the amount of suspended compounds that form the vapors (easy to test yourself and see firsthand). We help reduce blow-by by reducing ring flutter by not allowing pressure to build in the first place. We do ALL of this, while retaining a closed system and not venting smelly vapors into the engine compartment. Letís go over any questions on this if we havenít made it clearer. And again, if you disagree, please point out ANY form of Professional Racing (aside from Top Fuel/Alky classes where most oil is forced from the crankcase in one run and engine is rebuilt every run) venting today? No, it is outdated technology not used for decades. Remember, we are a company of actual Engineers and some with extensive experience in the Professional Racing World with the Championships to go with it. Out of all the talent in building power in this modern muscle car market, this is really the only area that no science seems to be used and only assumptions, and the Professional World looks at this and shakes their heads so much is not understood about proper crankcase evacuation. If you have more questions, you can always catch us at: Tech@EliteEngineeringUSA.com Or Sales@EliteEngineeringUSA.com Cheers! |

|

|

|

|

|

|

|

|

|

|

|