You are browsing camaro5

|

|

|

#155 | |

Drives: '16 C7 Z51 Join Date: May 2012

Location: Redmond, WA

Posts: 3,056

|

From my build thread:

Quote:

__________________

'16 Corvette C7 Z51 1LT (Build Thread)

'14 AGM 1SS 1LE [COTW 11/17/14] (Build Thread) (SOLD) '13 Mazda MX-5 Club (Build Thread) '17 RAM 1500 Crew Cab 4x4 Night Edition '15 Nissan Rogue S AWD |

|

|

|

|

|

|

#156 |

Drives: 2022 SS 1LE Join Date: Jul 2013

Location: San Jose, CA

Posts: 1,086

|

X25, excellent! Your solution has the advantage of a simple install and no custom shrouding. Nice work

__________________

Sold but not forgotten! Pedders Supercar Coilovers, 32mm rear sway bar,bushings; APR wing and splitter

Forged 416 road course stroker. 514 RWHP, 497 RW Ft-Lb 1 Camaro, 75 Vipers: http://www.camaro5.com/forums/showthread.php?t=393697 Buttonwillow Raceway: http://www.camaro5.com/forums/showthread.php?t=389086 |

|

|

|

|

|

#157 | |

|

When is enough ever...

Drives: 2006 Silverado 2500HD CC/SB LBZ Join Date: Apr 2011

Location: Residence: Chula Vista, CA Home: Billings, MT

Posts: 996

|

Quote:

Looks good. So a few questions for you. What cooler is it? -10 line size? What are seeing for pressure drop? I'm wrestling with what direction to go since my 25 row Mocal is not going to get it done. I spoke with Michael from improved racing and he thinks asking another 25 row Mocal will be more than enough to bring the temps in line. Two down sides are added cost and pressure drop. He estimates a 6 psi pressure drop through the two coolers run in series. I think I'm fine with that as I am more concerned with flow which should be good running the Melling 10296 ported pump. Anyhow, get to the track and get us some true numbers! I've got to make a decision soon as I've almost got my motor back together. Thanks.

__________________

The Project: 2011 Camaro 2SS/RS (ERL 427 Superdeck NA Monster)

"Just like farmer engineering. Find the weak link and fix it, then find the next one." Salt Cat Racing |

|

|

|

|

|

|

#158 | |

Drives: '16 C7 Z51 Join Date: May 2012

Location: Redmond, WA

Posts: 3,056

|

Quote:

Check out Setrab's list on cooling capacities vs. pressure drop, etc. http://www.setrabusa.com/products/oi...ine/index.html If this does not work (but I'm hoping it will), I might also switch to two cores. For my bother's 1LE, we'll do what I did with my supercharged Miata, and keep the OEM cooler. This way, OEM cooler will do 80% of required cooling, and the external oil cooler will have a much simpler job

__________________

'16 Corvette C7 Z51 1LT (Build Thread)

'14 AGM 1SS 1LE [COTW 11/17/14] (Build Thread) (SOLD) '13 Mazda MX-5 Club (Build Thread) '17 RAM 1500 Crew Cab 4x4 Night Edition '15 Nissan Rogue S AWD |

|

|

|

|

|

|

#159 | |

Drives: '16 C7 Z51 Join Date: May 2012

Location: Redmond, WA

Posts: 3,056

|

Quote:

__________________

'16 Corvette C7 Z51 1LT (Build Thread)

'14 AGM 1SS 1LE [COTW 11/17/14] (Build Thread) (SOLD) '13 Mazda MX-5 Club (Build Thread) '17 RAM 1500 Crew Cab 4x4 Night Edition '15 Nissan Rogue S AWD |

|

|

|

|

|

|

#160 |

|

Your new setup looks pretty stout X25! Should be able to handle anything you throw at it. I wasn't able to truly test out my setup at NCM since it was raining or wet all day. Got one session of completely dry track. I have to go back there sometime cause that track is awesome!

__________________

|

|

|

|

|

|

#161 |

|

Drives: Camaro Justice Join Date: Jun 2007

Location: Virginia

Posts: 20,174

|

|

|

|

|

|

|

#162 | |

|

Cadillac Service Manager

Drives: 2014 Camaro 1SS, 1LE, NPP, RECAROS Join Date: Jun 2013

Location: Indiana

Posts: 672

|

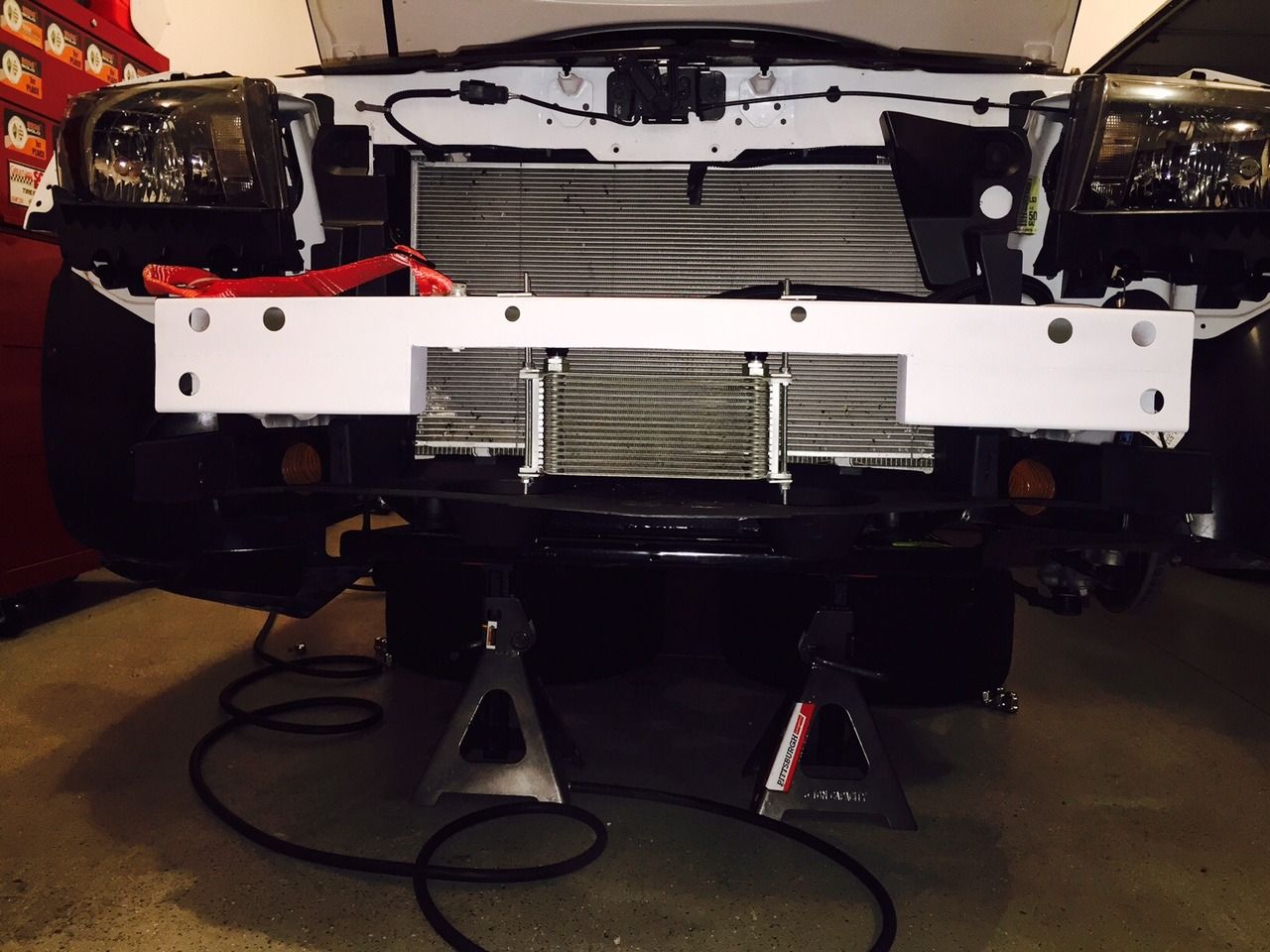

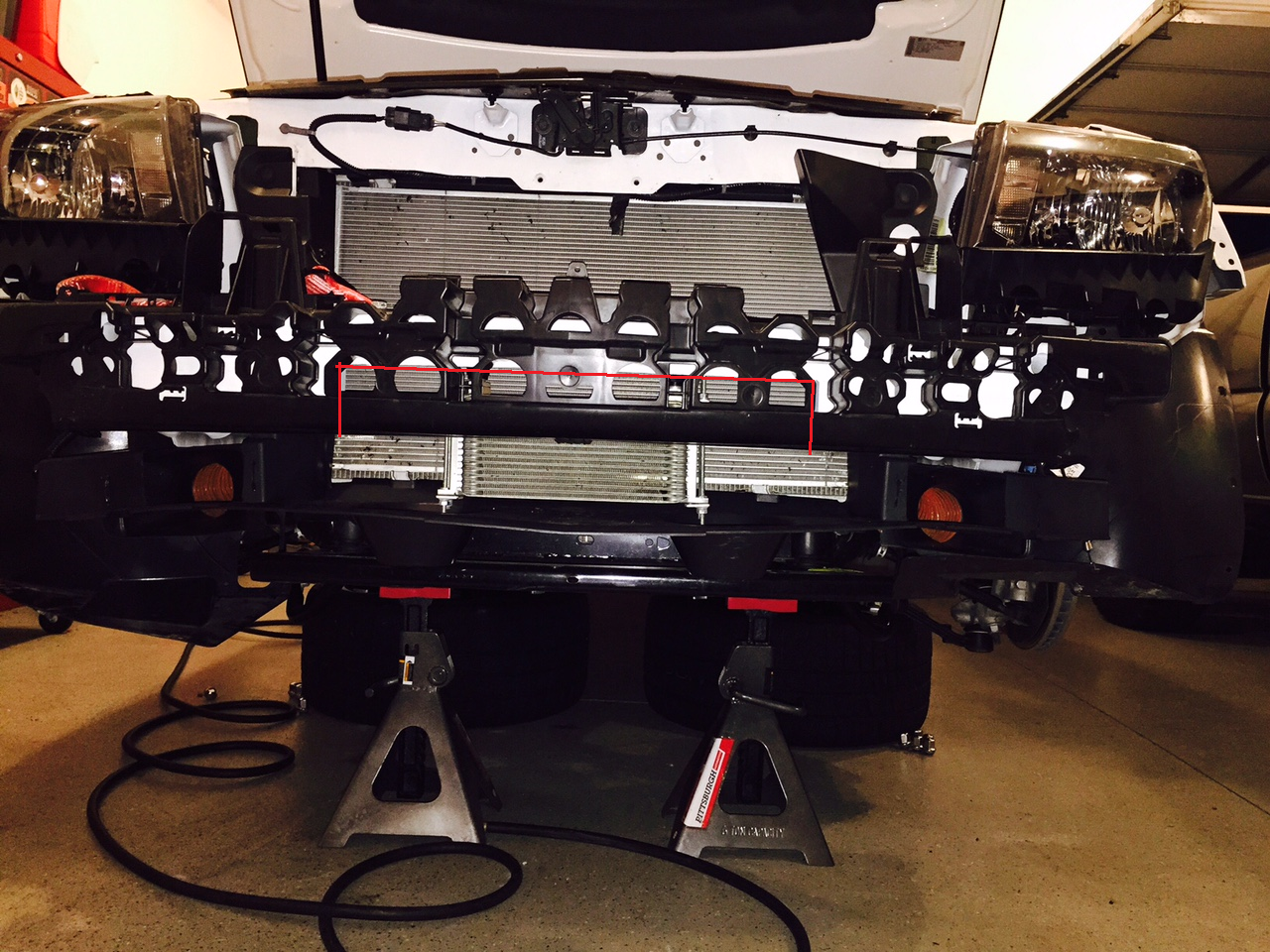

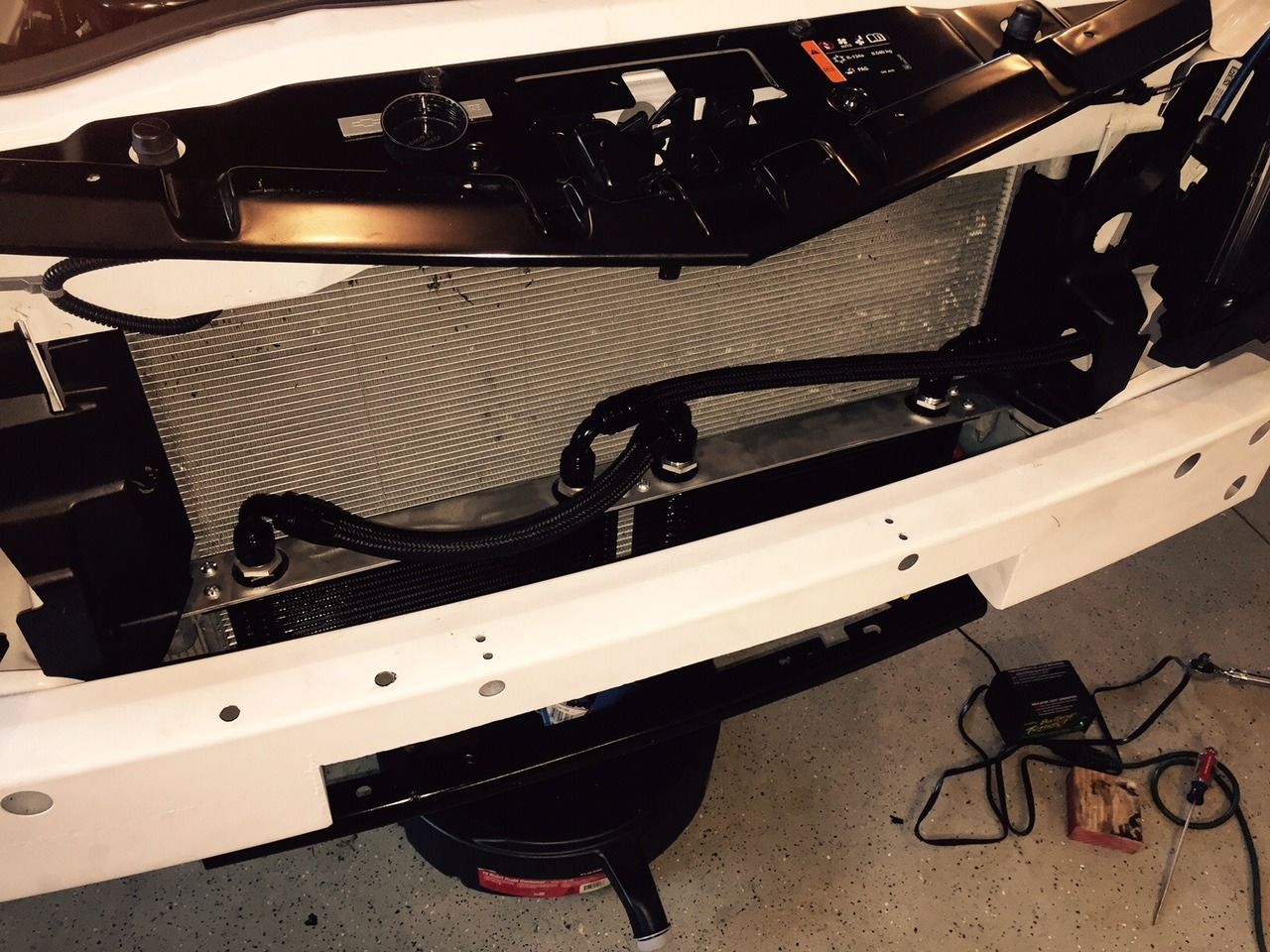

After completing another track day during a 85 degree day I found that my single oil cooler set up did not work. After a lot of searching on the Google machine looking at other peoples set ups and experiences, and a few oil cooling 101 documents I found I decided to upgrade my set up trying to use the parts that I have.

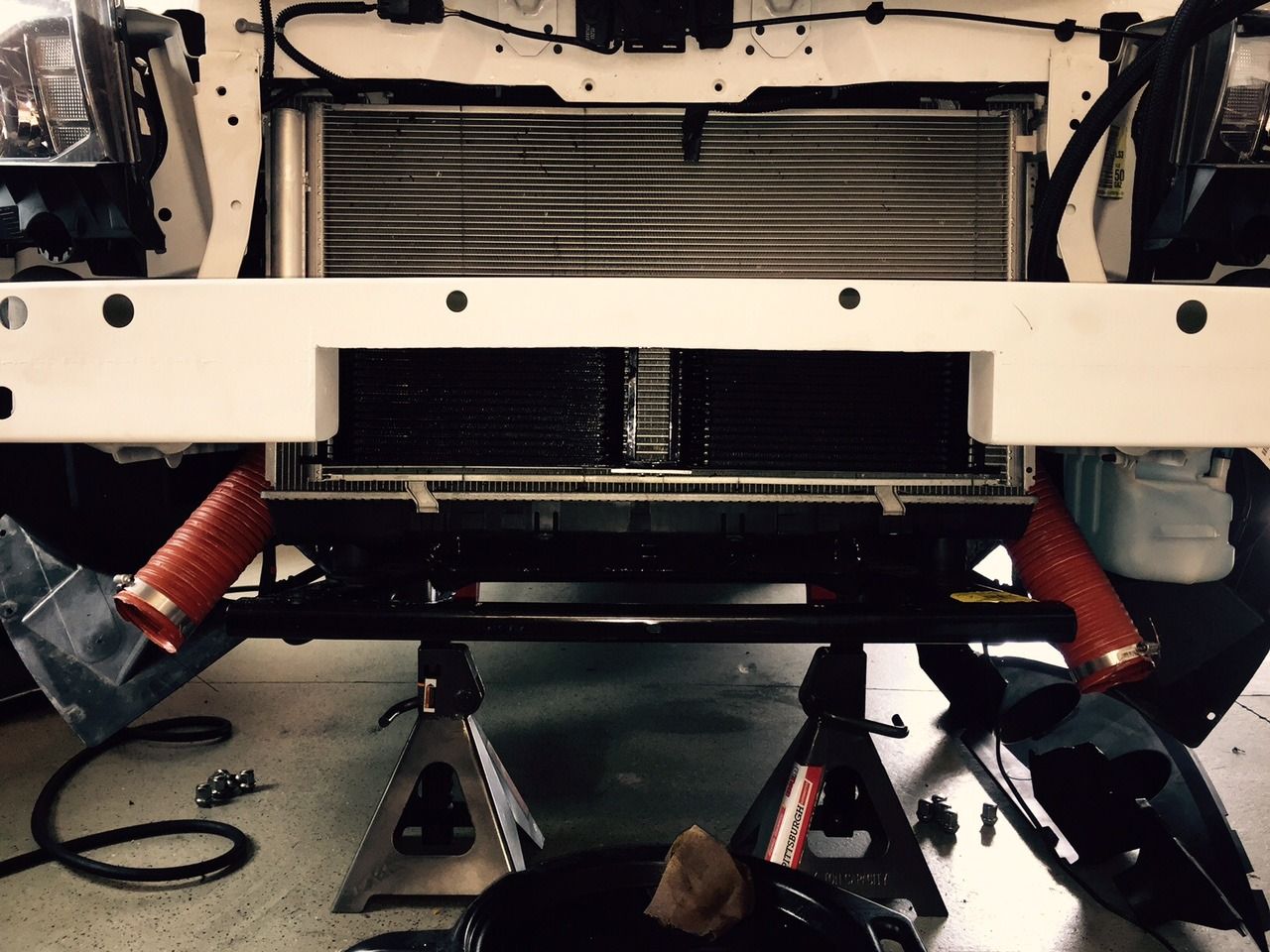

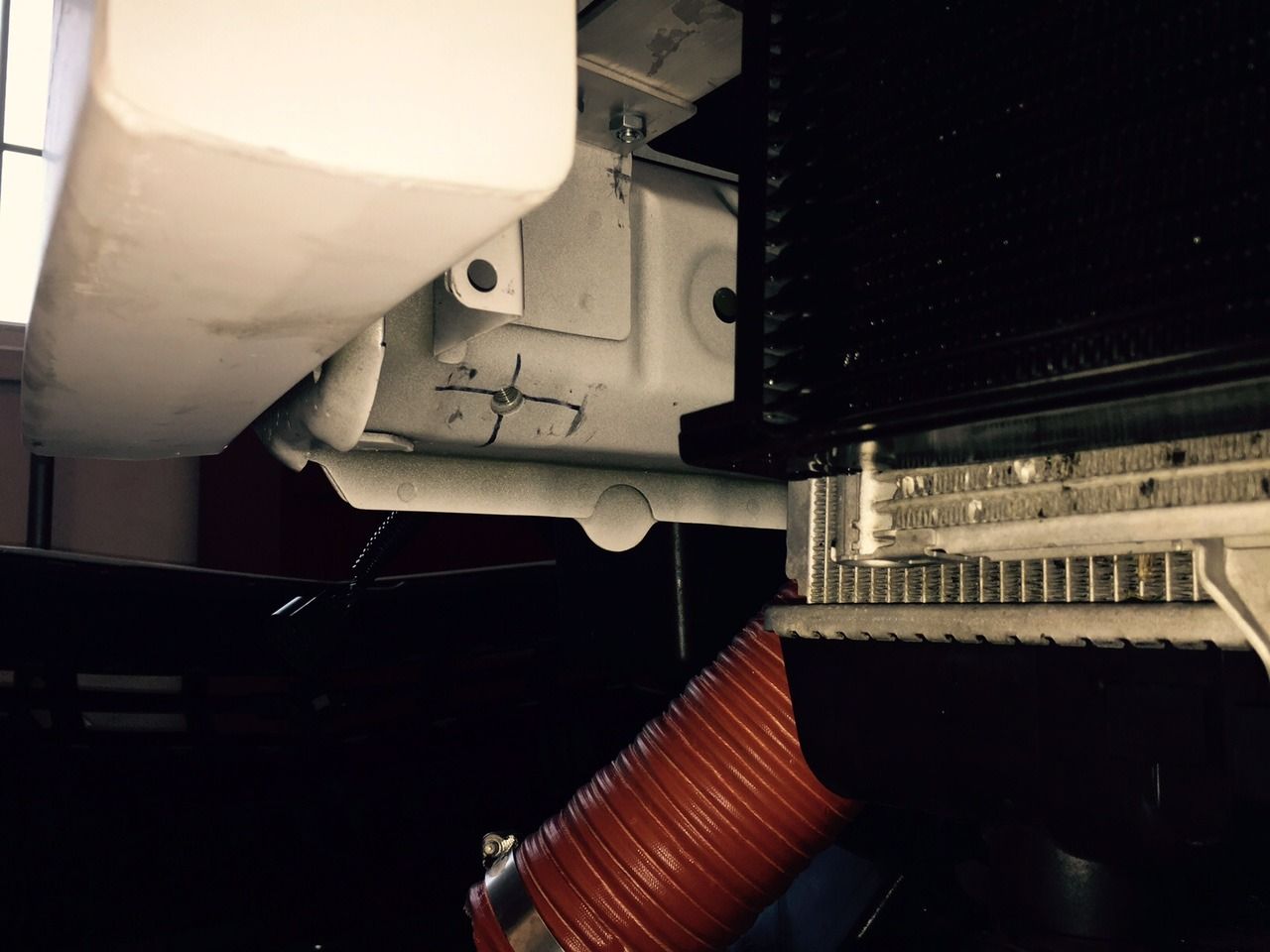

Air flow is a big part of cooling, and with half of my cooler being blocked a combination of the metal crash bar and the plastic piece that goes over the cash bar, some cutting was going to be required to let some more air in.  I ended up cutting the center section out of the crash bumper and boxing it in so it still have some strength.  I also trimmed the section seen here in the red to let more air through the lower grille opening.  For the coolers I wanted to use another Silver Earls 16 Row to match the cooler I already had, but found out that the silver was no longer made. I could feel the OCD building in side of me, so I ordered two black Earls 16 Row Oil Coolers (EAR-41600AERL). The cooler bodies are 13 inches wide, 5 inches high, and 2 inches thick. I made a custom bracket out of aluminum that I picked up at my local big box hardware store.  I was able to mount the coolers between two frame rails using the thin metal taps that are part of the frame rails. I forgot to take pictures of this before I put the black plastic factory air ducting back in (sorry). I also mounted the coolers a half inch from the AC condenser. I read that the close the cooler, condenser, and radiator are together, the less likely turbulent air will be formed passing through any of the said cooling components making air use much more efficient.  I was able to use a hole in both sides of the frame rails that was already threaded to mount my lower cooler brackets that I made by bending some more aluminum. I don't remember the size of the bolt, but I ended up taking the bottom bolt from the washer tank and trying it, and it was the correct size and thread pitch, so I took that bolt with me to find two more.  With the coolers installed I filled both coolers with oil and installed the hoses. I primed the oil system by holding the accelerator to the floor while cranking the engine (this cuts the injectors and will not let an fuel in to the cylinders) for 10 seconds then taking 30 second brakes. I repeated this 4 times.  I started the car and quickly jumped out to check on my cooler only to find a large amount of oil coming from the passenger side cooler. I shut the engine down and started my investigation. The oil was coming from the top outside port area, but I couldn't tell if it was the cooler or the fittings so I swapped the left and right fitting and tried again. Oil still leaking from the same side, so it was the cooler. I wanted to take the car out the next morning for a car party my friend was having so I ended up installed the silver cooler that I took off (same cooler just silver) and after a 15 minute swap job, no more leaks. I let the car get hot monitoring the oil PSI at different RPMS. 1,000 RPM oil pressure was 41 psi (minimum is 24), 2,000 RPM oil pressure was 48 psi (minimum is 35), 3,000 RPM oil pressure was 61 psi (minimum is 38). After about 45 minutes of running I checked everything over to make sure I didn't have leaks, then reinstalled the front bumper. Unless you get down and look with a light you can't even tell that the silver cooler is there. I ended up sending the bad black one back and getting another that I will install this winter when I'm not driving the car. I outlet the area of the black plastic inside bumper cover that I trimmed to let more air in. I drove the car for a few days checking and rechecking to make sure no leaks had developed as I had a track day coming in a week.  Results: It worked! My first track session was early afternoon, and the ambient temp was 85 degrees. I think the hottest I saw was 275 in my first session. The only issue I had was a lot of fluctuation in the gauge (auto meter 6348 Sport Comp Digital Temp Gauge with sensor). The sensor is monitoring oil going to the cooler. At times the gauge would drop 100 degrees, or all the way 0 at times, but oil pressure was fine. I'm thinking I have a wiring issue. The gauge read accurate when the car was in a straight line. The video is my 2nd session. I have another track day Sept 13th at a different track.

__________________

|

|

|

|

|

|

|

#163 |

|

When is enough ever...

Drives: 2006 Silverado 2500HD CC/SB LBZ Join Date: Apr 2011

Location: Residence: Chula Vista, CA Home: Billings, MT

Posts: 996

|

Quote:

__________________

The Project: 2011 Camaro 2SS/RS (ERL 427 Superdeck NA Monster)

"Just like farmer engineering. Find the weak link and fix it, then find the next one." Salt Cat Racing |

|

|

|

|

|

#164 |

|

Cadillac Service Manager

Drives: 2014 Camaro 1SS, 1LE, NPP, RECAROS Join Date: Jun 2013

Location: Indiana

Posts: 672

|

The cooler didn't interfere with the ducts at all. The ducts are on the outside of the factory radiator ducting and my oil cooler stays inside of that ducting if that makes sense.

__________________

|

|

|

|

|

|

#165 |

|

When is enough ever...

Drives: 2006 Silverado 2500HD CC/SB LBZ Join Date: Apr 2011

Location: Residence: Chula Vista, CA Home: Billings, MT

Posts: 996

|

I'm going to have to look into this a bit. I am wondering if the lower grill is wider on your year than on the 2011? I think I can just run two Mocal 235 25 row cooler side by side but I have two concerns. One is making sure I've got the room for the brake ducts and the other is making sure I've got room to run the connecting line between the two. Might have to get creative with the hook ups and line routing.

__________________

The Project: 2011 Camaro 2SS/RS (ERL 427 Superdeck NA Monster)

"Just like farmer engineering. Find the weak link and fix it, then find the next one." Salt Cat Racing |

|

|

|

|

|

#166 | |

Drives: '16 C7 Z51 Join Date: May 2012

Location: Redmond, WA

Posts: 3,056

|

Quote:

We should also discuss the conditions (track type), power levels, ambient temps, and also the average RPMs when comparing results. If you're not using the whole motor (shifting before redline, coasting to break zones, etc.), then the results might get misleading, at least in comparison with others'.

__________________

'16 Corvette C7 Z51 1LT (Build Thread)

'14 AGM 1SS 1LE [COTW 11/17/14] (Build Thread) (SOLD) '13 Mazda MX-5 Club (Build Thread) '17 RAM 1500 Crew Cab 4x4 Night Edition '15 Nissan Rogue S AWD |

|

|

|

|

|

|

#167 |

|

Cadillac Service Manager

Drives: 2014 Camaro 1SS, 1LE, NPP, RECAROS Join Date: Jun 2013

Location: Indiana

Posts: 672

|

I'll try harder next track day.

__________________

|

|

|

|

|

|

#168 | |

|

When is enough ever...

Drives: 2006 Silverado 2500HD CC/SB LBZ Join Date: Apr 2011

Location: Residence: Chula Vista, CA Home: Billings, MT

Posts: 996

|

Quote:

__________________

The Project: 2011 Camaro 2SS/RS (ERL 427 Superdeck NA Monster)

"Just like farmer engineering. Find the weak link and fix it, then find the next one." Salt Cat Racing |

|

|

|

|

|

|

|

|

|

|

|