So after purchasing a wide band af gauge for my 2013 SS, I began looking at how other people mounted their gauges for ideas. The majority I found were mounted ontop of the steering column (100 bucks for that plastic mount/didnt like the location and too much $$$) and on their a-pillar(cost about the same). I only wanted to mount one gauge in my car for the time being and wanted a sleek clean look. I saw a picture of one that was mounted in the driver side a/c vent. It looked crappy, wasnt centered, etc. I knew this is where I wanted to mount mine, but could not find any good descriptive clean DIY's to guide me. So I came up with my own way and made this DIY. Hope this helps the many people who are wanting to mount their gauge here

and are not sure how. Instead of paying a shop to mill one out of aluminum like I have seen for different cars for crazy amounts of money, this can be done easily by yourself.It just requires patience. If you already have a colection basic tools, bondo and paint are only 20 bucks tops.

Tools:

-Trim removal tool(not required but recommended)

-7mm rachet

-Drill

-Dremel tool w/ consumable kit

-Ruler

-Marker

-Bondo

-Paint/vinyl wrap

-Sandpaper (rough and fine grit)

-Adhesive (hot glue, silicone, etc.)

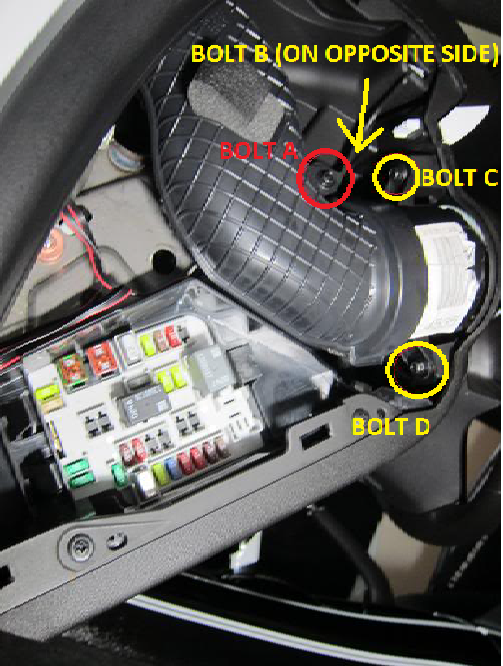

1. Ok so start by taking the driver side fuse box panel off (it just pops right out) and remove the bolt securing the air duct (BOLT A). Pull that duct out.

2. Remove the three bolts holding the vent assembly in place(BOLT B, BOLT C, AND BOLT D). There is a bolt on the top, bottom and on the side. The side bolt is kind of tricky as there isnt much room to work with and

its hard to see. I used a 7mm deep socket to get it.

2.Once these bolts are removed, the vent assembly comes out easily. Take the bezel(PIECE 1) off using the 3 clips holding it together on the sides (this is the thin silver piece). Then pull the other two pieces apart via the clips on the inside holding them together. You should be left with above pieces pictured.

3. Once you do this, cut off or trim the grate on the back side of PIECE 2 (the piece that has the 3 plastic brackets on it for mounting). Scuff the inside with sandpaper so the bondo will adhear to it.

4. Fill her up with bondo!! I filled mine a little past half way. Adjust as necessary for your specific gauge. Fill the vent with bondo face down on a clean flat surface. I used a magazine cover. When it dries you have a nice flat front side. Should look like this when done.

******It is very important you get the ratio right when you mix your bondo! If you put too much hardener in the mix, once it dries, it will be very brittle and might crack during drilling,and sanding stage. Get your ratios correct and mix well*******

5. Once that is dry (should be dry in about 20 - 30 minutes), find the center of the bondo'd area as shown. Measure the diameter of the gauge (not the bezel ring on the front of the gauge, but the opposite end of the gauge itself). You want it to be small enough to slide the gauge in your hole and then have the gauge bezel/cap cover up the edges of your hole so it looks clean.

6.Once you find the center and mark your circle, use a drill to get a hole in the center. Then use a dremel or however you wish to widen the hole to proper size. Always start small and check the fitment of your gauge frequently.

7.Once you are able to slide your gauge in the hole and are done widening, clean up rough spots with sandpaper until you have a smooth surface. Use fine grit to finish.

8. Now you are ready to paint it or wrap it. I had some vinyl wrap laying around so I wrapped mine.

9. After your paint has cured or you are dont wrapping it, slide your gauge in and secure your gauge using an adhesive of your choosing. Apply your adhesive to the back side of the gauge. I used silicone glue so I can remove it easily if need be. A hot glue gun would have probably been a quicker cure now that i think about it. (If your hole is right on the money, you wont even need adhesive!!)

**This took about an hour and half to do and is pretty easy. Just take your time, check your measurements and check the fitment of the gauge frequently.**

[ATTACH][ATTACH]

[/ATTACH][/ATTACH]

New to the forum since I just got my 1LE, so figured I would start by posting this. Enjoy