After completing another track day during a 85 degree day I found that my single oil cooler set up did not work. After a lot of searching on the Google machine looking at other peoples set ups and experiences, and a few oil cooling 101 documents I found I decided to upgrade my set up trying to use the parts that I have.

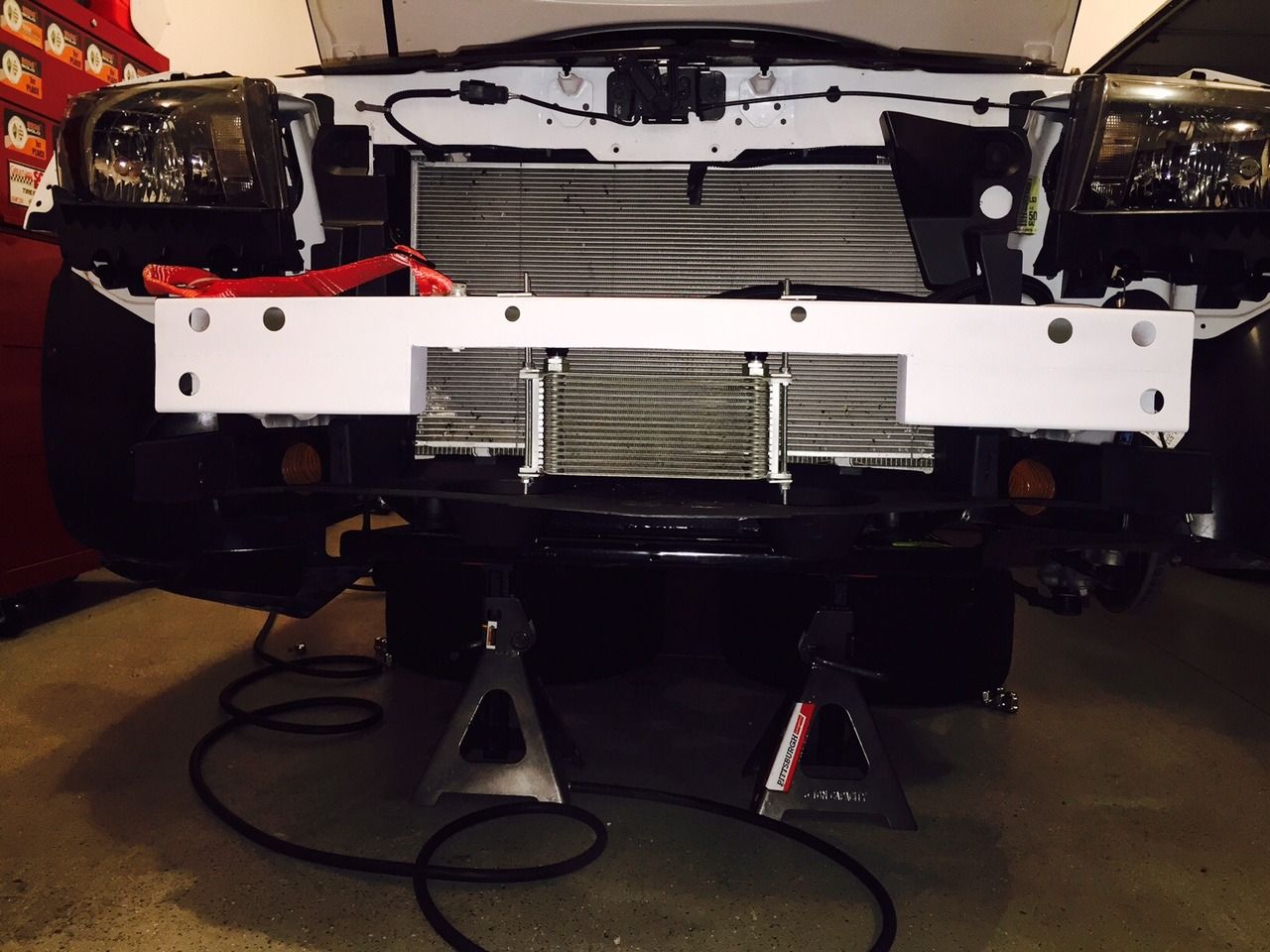

Air flow is a big part of cooling, and with half of my cooler being blocked a combination of the metal crash bar and the plastic piece that goes over the cash bar, some cutting was going to be required to let some more air in.

I ended up cutting the center section out of the crash bumper and boxing it in so it still have some strength.

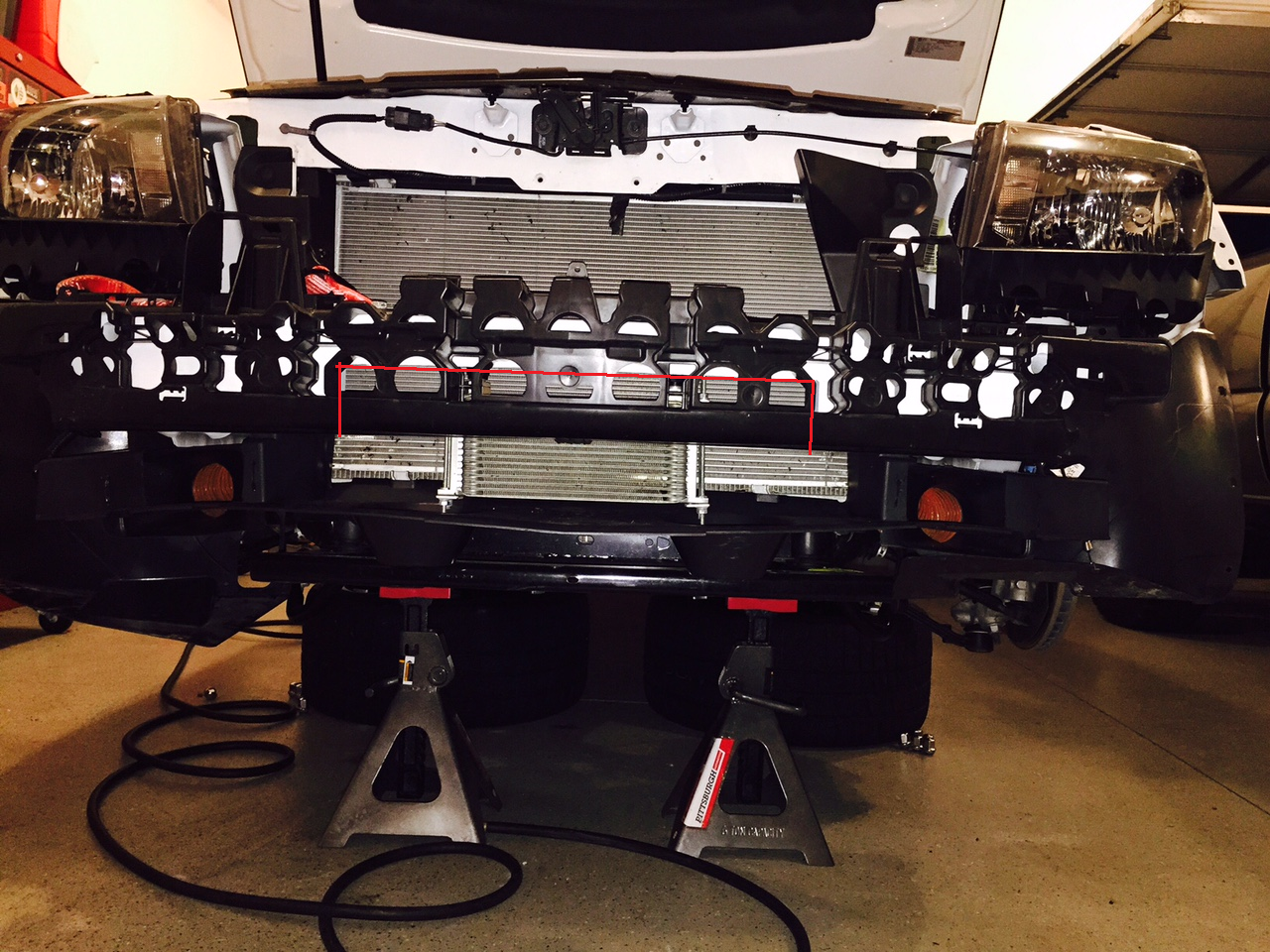

I also trimmed the section seen here in the red to let more air through the lower grille opening.

For the coolers I wanted to use another Silver Earls 16 Row to match the cooler I already had, but found out that the silver was no longer made.

I could feel the OCD building in side of me, so I ordered two black Earls

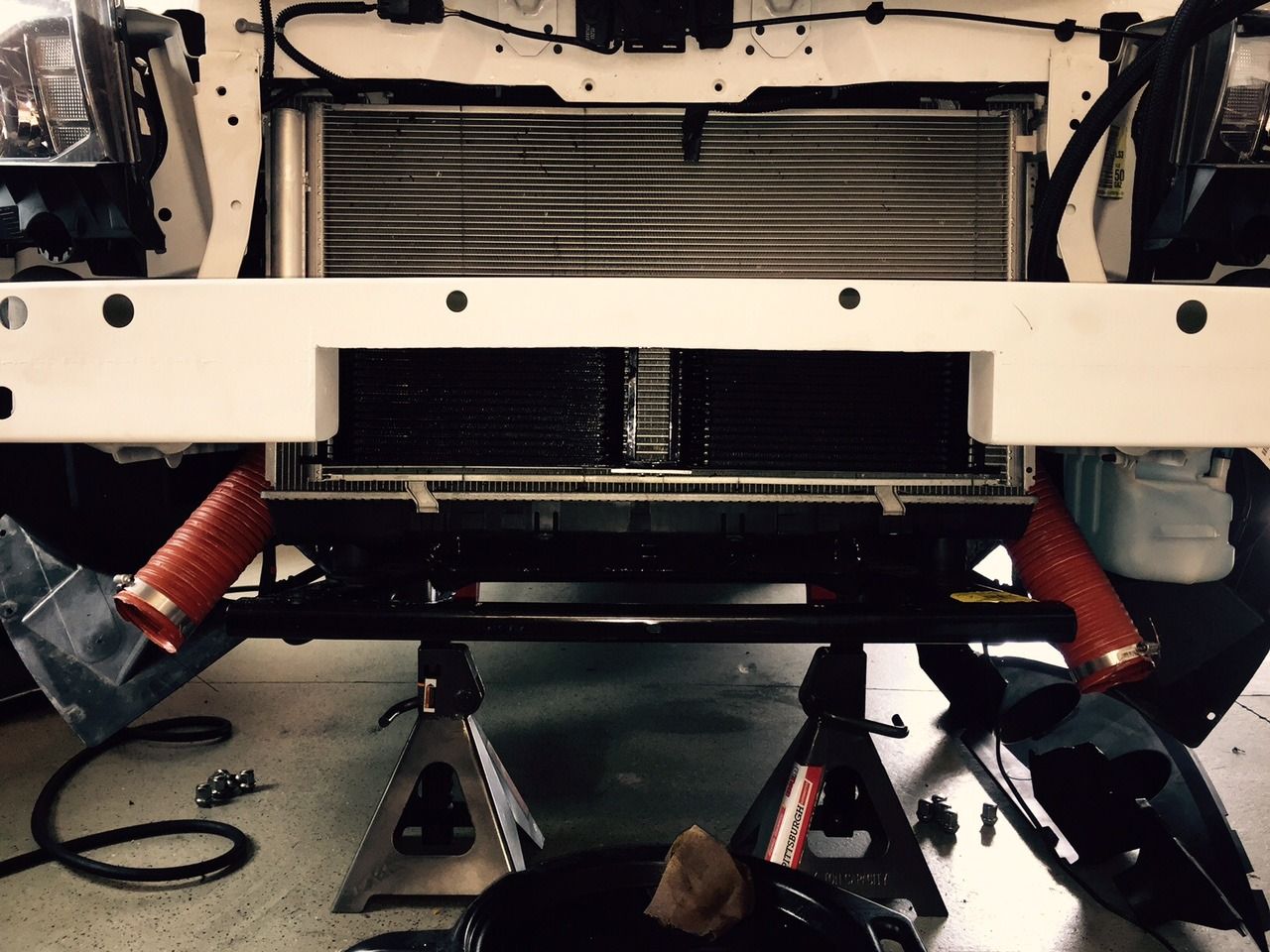

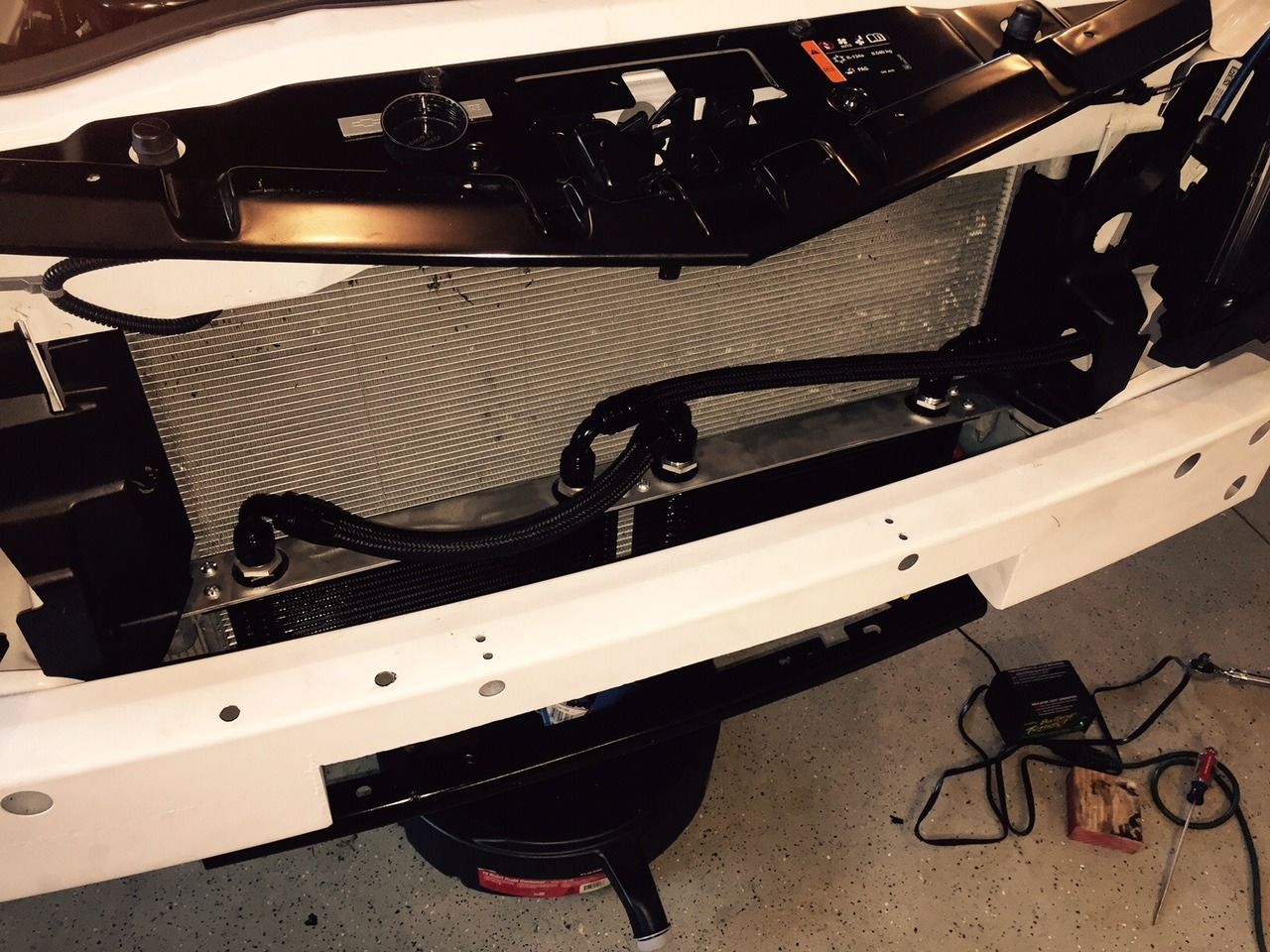

16 Row Oil Coolers (EAR-41600AERL). The cooler bodies are 13 inches wide, 5 inches high, and 2 inches thick. I made a custom bracket out of aluminum that I picked up at my local big box hardware store.

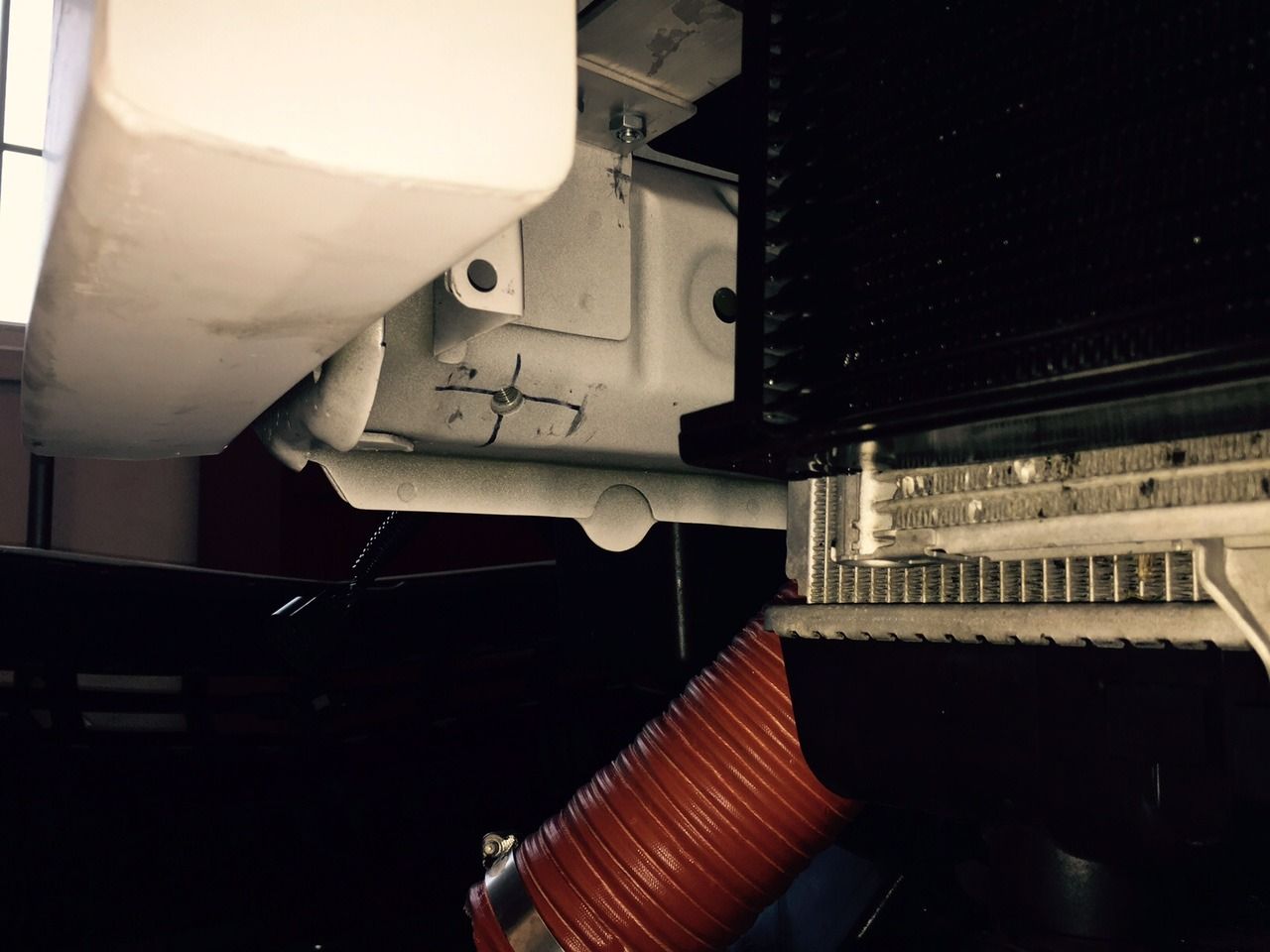

I was able to mount the coolers between two frame rails using the thin metal taps that are part of the frame rails. I forgot to take pictures of this before I put the black plastic factory air ducting back in (sorry). I also mounted the coolers a half inch from the AC condenser. I read that the close the cooler, condenser, and radiator are together, the less likely turbulent air will be formed passing through any of the said cooling components making air use much more efficient.

I was able to use a hole in both sides of the frame rails that was already threaded to mount my lower cooler brackets that I made by bending some more aluminum. I don't remember the size of the bolt, but I ended up taking the bottom bolt from the washer tank and trying it, and it was the correct size and thread pitch, so I took that bolt with me to find two more.

With the coolers installed I filled both coolers with oil and installed the hoses. I primed the oil system by holding the accelerator to the floor while cranking the engine (this cuts the injectors and will not let an fuel in to the cylinders) for 10 seconds then taking 30 second brakes. I repeated this 4 times.

I started the car and quickly jumped out to check on my cooler only to find a large amount of oil coming from the passenger side cooler.

I shut the engine down and started my investigation. The oil was coming from the top outside port area, but I couldn't tell if it was the cooler or the fittings so I swapped the left and right fitting and tried again. Oil still leaking from the same side, so it was the cooler. I wanted to take the car out the next morning for a car party my friend was having so I ended up installed the silver cooler that I took off (same cooler just silver) and after a 15 minute swap job, no more leaks. I let the car get hot monitoring the oil PSI at different RPMS. 1,000 RPM oil pressure was 41 psi (minimum is 24), 2,000 RPM oil pressure was 48 psi (minimum is 35), 3,000 RPM oil pressure was 61 psi (minimum is 38). After about 45 minutes of running I checked everything over to make sure I didn't have leaks, then reinstalled the front bumper. Unless you get down and look with a light you can't even tell that the silver cooler is there. I ended up sending the bad black one back and getting another that I will install this winter when I'm not driving the car. I outlet the area of the black plastic inside bumper cover that I trimmed to let more air in.

I drove the car for a few days checking and rechecking to make sure no leaks had developed as I had a track day coming in a week.

Results:

Results:

It worked! My first track session was early afternoon, and the ambient temp was 85 degrees. I think the hottest I saw was 275 in my first session. The only issue I had was a lot of fluctuation in the gauge (auto meter 6348 Sport Comp Digital Temp Gauge with sensor). The sensor is monitoring oil going to the cooler. At times the gauge would drop 100 degrees, or all the way 0 at times, but oil pressure was fine. I'm thinking I have a wiring issue. The gauge read accurate when the car was in a straight line. The video is my 2nd session. I have another track day Sept 13th at a different track.