05-22-2010, 08:06 PM

05-22-2010, 08:06 PM

|

#1

|

Drives: 2014 Ford Focus ST

Join Date: Jun 2009

Location: Tampa Bay

Posts: 939

|

Removing Swirl Marks using a Flex and Meguiars M105/M205

In response to a question about removing swirls on a Corvette. The techniques described will work on most paint systems

What is causing the 'swirl effect' in your paint in direct light is actually thousands and thousands of micro (and macro)scopic scratches that are catching light at an angle. Most of the these scratches are actually straight or oblong, but it is the the way the furtherest edge of the scratch from the light source catches the light in the thousands of scratches that gives them that cobbweb effect.

Here is a quick drawing I did showing a cross section of the top layer (clear coat) of paint. lots of GM vehicle's are painted with a base coat/clear coat system, so that the color is actually in the second layer of paint. The top is clear and responsible for the gloss and depth. On average the clear coat is about 2.0-2.5 mils thick, or a slightly thicker then a sheet of notebook paper. As you can see in the picture, most swirl mark scratches are very shallow. You can safely remove them from the paint with out removing any measurable thickness.

To remove the swirl marks you must 're-level' the paint so that all paint above the valleys of the scratches are removed, and the paint is now smooth and even. This means you will be removing a small amount of paint from the car, although this sounds much more scary then it is in application.

To remove the swirl marks you must 're-level' the paint so that all paint above the valleys of the scratches are removed, and the paint is now smooth and even. This means you will be removing a small amount of paint from the car, although this sounds much more scary then it is in application.

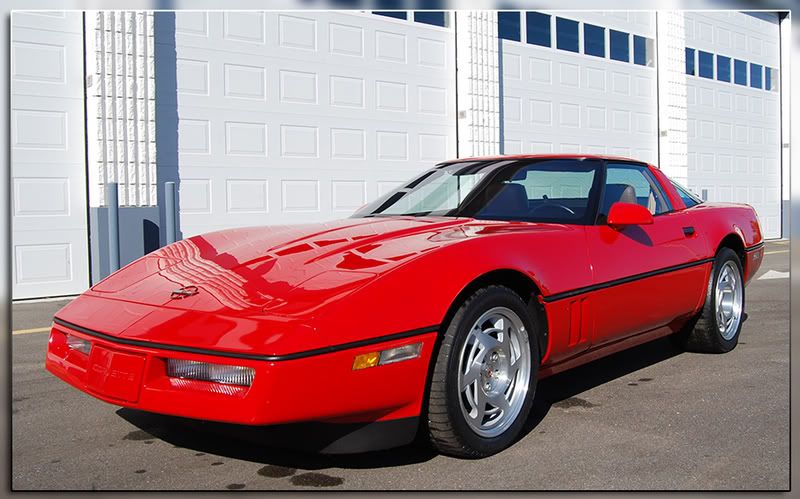

The benefit of having smooth and level paint (besides the obvious fact that the swirl marks are gone) is that the paint will reflect with a greater vibrance. As light hits the angles of the scratches it shoots back at a different angle. This diffusion of the light will dull the reflections. This 1990 ZR1 was pretty rough and heavily scratched. The benefit of re-leveling the scratches then final polishing to a super high gloss is not only are the defects removed, but the paint looks absolutely alive or 'pops'. It might even look better then it did in 1990.

The benefit of having smooth and level paint (besides the obvious fact that the swirl marks are gone) is that the paint will reflect with a greater vibrance. As light hits the angles of the scratches it shoots back at a different angle. This diffusion of the light will dull the reflections. This 1990 ZR1 was pretty rough and heavily scratched. The benefit of re-leveling the scratches then final polishing to a super high gloss is not only are the defects removed, but the paint looks absolutely alive or 'pops'. It might even look better then it did in 1990.

Most swirl marks are caused by improper washing and drying. Any time grit is rubbed against the surface in the washing (or drying process) the grit abrades the surface causing the micro scratches. With modern, scratch sensitive clear coats, the act of removing dirt from the paint with out scratching the it is almost an art forum. I have been working on a write up for this forum, showing what I feel are sure-fire techniques to give you the absolute best chance at preventing new swirls and scratches. I will post a link to it here when it is up (by the end of the week).

What is more dangerous, improper washing or machine polishing your paint?

Since the act of removing swirl marks is nothing more then removing the peaks of the scratches, you are removing the paint 'left behind' by improper washing. It can take the better part of two days to fully remove every scratch and swirl mark, or remove the paint left behind, from just one improper wash! Improper washing and drying removes far deeper amounts of paint then 15 minutes of scrubbing grit and grime against the paint.

Understanding Machine Polishing, Selecting the Correct Tools

Selecting the Correct Machine.

There are four main types of machines: The Orbital Polisher, The Random Orbital Polisher, The Dual Action Polisher (orbit and rotation), and The Rotary Polisher.

The Orbital Polisher is similar to the 'wax master' machines found at most retail locations. These usually feature a large (9-11 inch) fixed pad and different bonnets. These machines usually do not have enough power and the pad is too large to remove paint. While these machines may do a good job of spreading thin layers of glaze, sealant, or wax, they really are not suitable for paint correction.

The Random Orbital Polisher (ROB) is a great choice for novice enthusiasts and professional detailers alike. Popular models such as the Porter Cable 7424 and the Meguiar's G110 have changeable backing plates which allow for a variety professional polishing pads to be used. These machines do not have a forced rotation, like an orbital polisher, the pad actually 'giggles' in a random motion. A counter weight and centripetal force act to make the pad rotate, although there is no direct link. This giggling motion mimics the motion of your hand, only at a much faster rate. ROB polishers are also variable in speed from a low end of around 2000 orbits per minute to a high end of 6000 to 7000 opm. Depending on the pad and speed used, ROB polishers are great for removing swirls from most paints and applying waxes and sealants.

Corvette amd some of other GM vehicle's paint is generally very hard and scratch resistant. The Porter Cable and Meguiar's G110 may not have enough power to fully remove swirl marks from modern Vette's paint.

The Dual Action (forced rotation Random Orbital Polisher) is really a jack of all trades. DA polishers combine a forced rotation of the pad, similar to a rotary polisher, and the random oscillation of an orbital polisher. Since the oscillating action prevents heat build up, there is little risk of burning the paint. On the hard C5 and C6 Corvette paint, the Flex Dual Action Polisher will likely give the best compromise between having the power to get the job done and being safe enough to mitigate the risk of damage. These polishers are generally more powerful then Random Orbital Polishers and have speeds from 3000 to 9000opm and rotate the pad between 160-480rpm.

The Rotary Polisher (circular polisher, variable speed polisher, high-speed polisher) is the choice of most professionals. The pad has a forced rotation. There is no oscillating action, so the only safety link of between is the person behind the tool. Rotary polishers remove paint much quicker then other machines, and in the right hands can finish the paint to the highest level, they also require the most practice to get great results out of. In general these machines have variable speeds between 600-3000rpms (as opposed to 480 rpms for the most power dual action polishers).

For most GM owners, because the harder paint finish, I really feel the Flex 3401VRG is the ideal machine and the best compromise between safety and having the power to get the job done.

Most swirl marks are caused by improper washing and drying. Any time grit is rubbed against the surface in the washing (or drying process) the grit abrades the surface causing the micro scratches. With modern, scratch sensitive clear coats, the act of removing dirt from the paint with out scratching the it is almost an art forum. I have been working on a write up for this forum, showing what I feel are sure-fire techniques to give you the absolute best chance at preventing new swirls and scratches. I will post a link to it here when it is up (by the end of the week).

What is more dangerous, improper washing or machine polishing your paint?

Since the act of removing swirl marks is nothing more then removing the peaks of the scratches, you are removing the paint 'left behind' by improper washing. It can take the better part of two days to fully remove every scratch and swirl mark, or remove the paint left behind, from just one improper wash! Improper washing and drying removes far deeper amounts of paint then 15 minutes of scrubbing grit and grime against the paint.

Understanding Machine Polishing, Selecting the Correct Tools

Selecting the Correct Machine.

There are four main types of machines: The Orbital Polisher, The Random Orbital Polisher, The Dual Action Polisher (orbit and rotation), and The Rotary Polisher.

The Orbital Polisher is similar to the 'wax master' machines found at most retail locations. These usually feature a large (9-11 inch) fixed pad and different bonnets. These machines usually do not have enough power and the pad is too large to remove paint. While these machines may do a good job of spreading thin layers of glaze, sealant, or wax, they really are not suitable for paint correction.

The Random Orbital Polisher (ROB) is a great choice for novice enthusiasts and professional detailers alike. Popular models such as the Porter Cable 7424 and the Meguiar's G110 have changeable backing plates which allow for a variety professional polishing pads to be used. These machines do not have a forced rotation, like an orbital polisher, the pad actually 'giggles' in a random motion. A counter weight and centripetal force act to make the pad rotate, although there is no direct link. This giggling motion mimics the motion of your hand, only at a much faster rate. ROB polishers are also variable in speed from a low end of around 2000 orbits per minute to a high end of 6000 to 7000 opm. Depending on the pad and speed used, ROB polishers are great for removing swirls from most paints and applying waxes and sealants.

Corvette amd some of other GM vehicle's paint is generally very hard and scratch resistant. The Porter Cable and Meguiar's G110 may not have enough power to fully remove swirl marks from modern Vette's paint.

The Dual Action (forced rotation Random Orbital Polisher) is really a jack of all trades. DA polishers combine a forced rotation of the pad, similar to a rotary polisher, and the random oscillation of an orbital polisher. Since the oscillating action prevents heat build up, there is little risk of burning the paint. On the hard C5 and C6 Corvette paint, the Flex Dual Action Polisher will likely give the best compromise between having the power to get the job done and being safe enough to mitigate the risk of damage. These polishers are generally more powerful then Random Orbital Polishers and have speeds from 3000 to 9000opm and rotate the pad between 160-480rpm.

The Rotary Polisher (circular polisher, variable speed polisher, high-speed polisher) is the choice of most professionals. The pad has a forced rotation. There is no oscillating action, so the only safety link of between is the person behind the tool. Rotary polishers remove paint much quicker then other machines, and in the right hands can finish the paint to the highest level, they also require the most practice to get great results out of. In general these machines have variable speeds between 600-3000rpms (as opposed to 480 rpms for the most power dual action polishers).

For most GM owners, because the harder paint finish, I really feel the Flex 3401VRG is the ideal machine and the best compromise between safety and having the power to get the job done.

|

|

|