You are browsing camaro5

|

|

|

#1 |

|

Fabrication issue need advice please

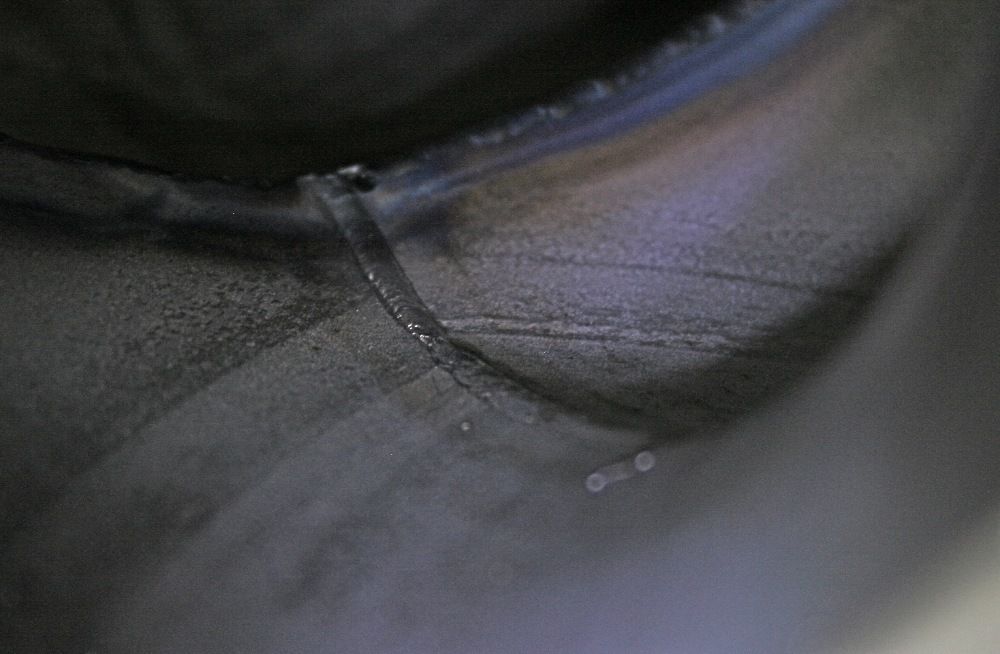

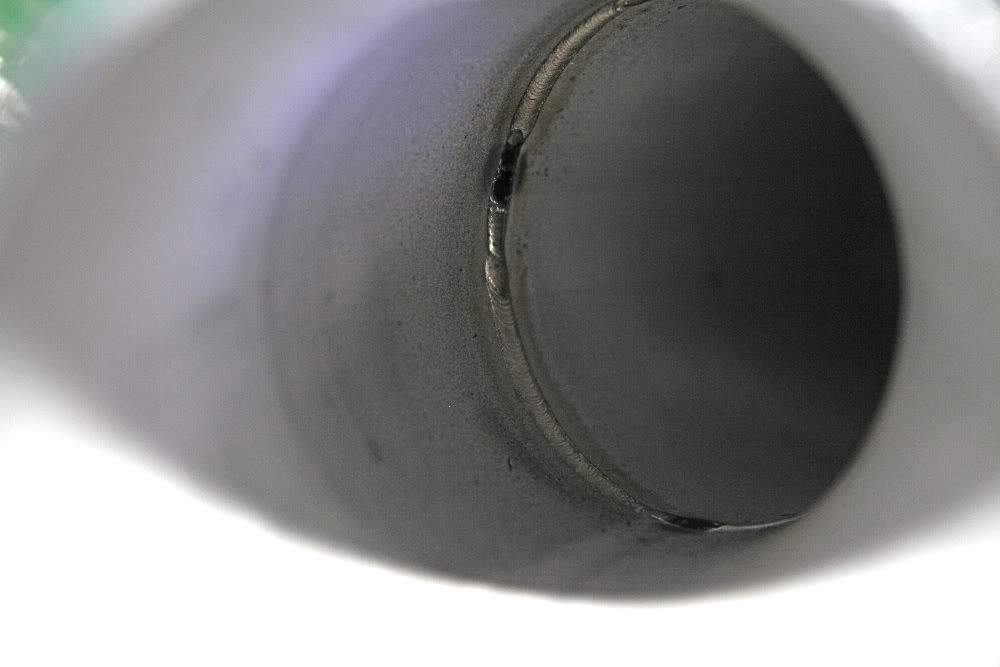

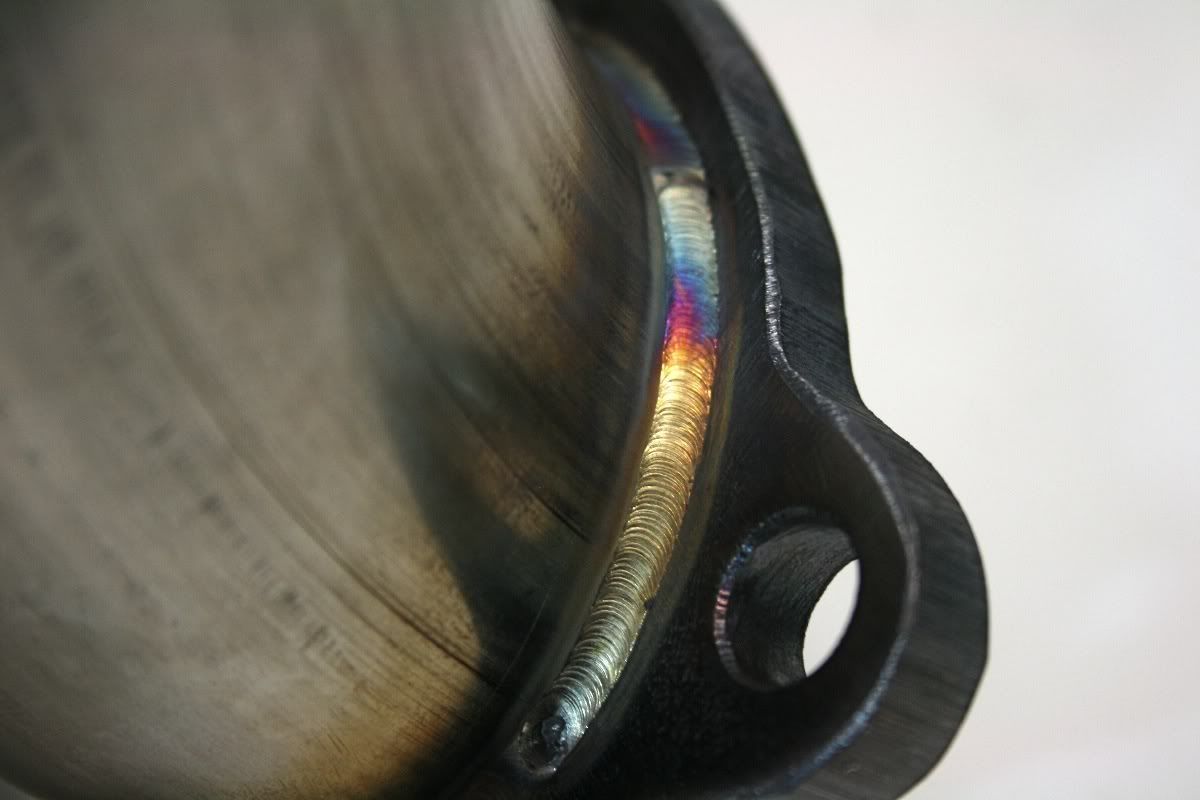

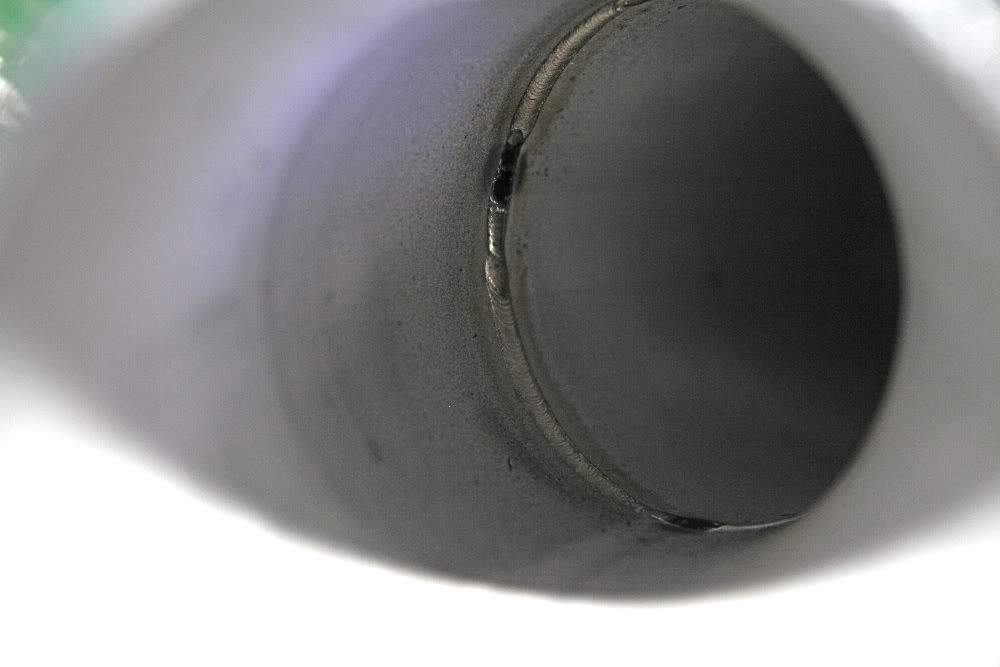

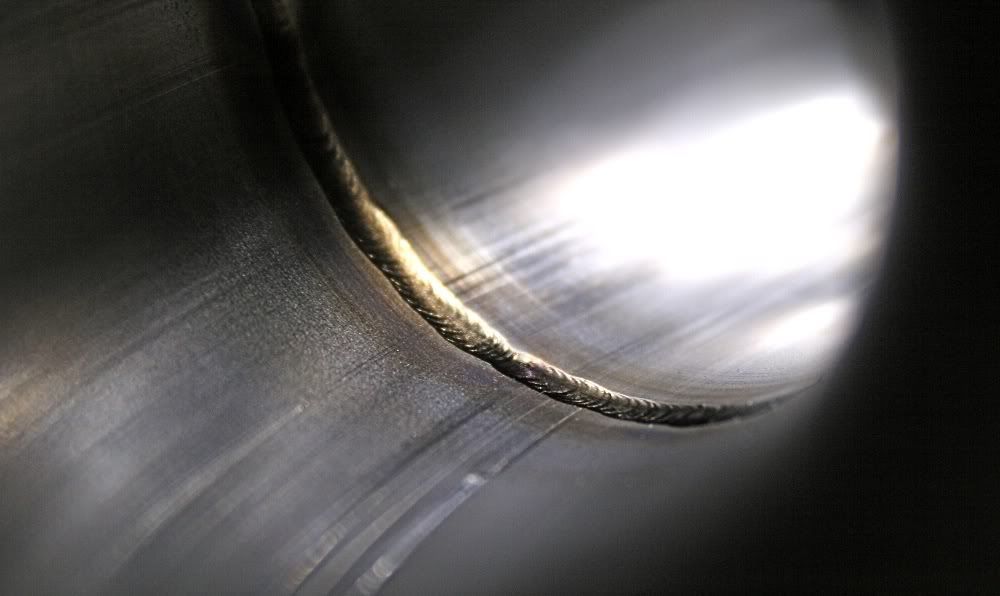

So I have a turbo kit that most people have either read about or seen the pictures of. Well I got everything, that I could reach, cleaned up and it looks decent. Well I decided to break out the boreiscope and check where the hot pipes were welded at the joints. Well when they cut the pipes they were not debured at all so once it was welded together it left a bunch of metal protruding out of the welds and slag on the inside of the pipes. Needless to say if I leave it this way and install the kit these shavings and slag are going to start coming off and going into the turbo. I am guessing that this will be a bad thing? Well I can not reach these areas to clean up the fab work like I did the rest so how in the hell do I fix this issue? Is there a special tool that I can buy that I don't know about? The only thing that I can think of is to install the hot pipes and crank the car up to burn and blow this stuff off. I am stuck, help please.

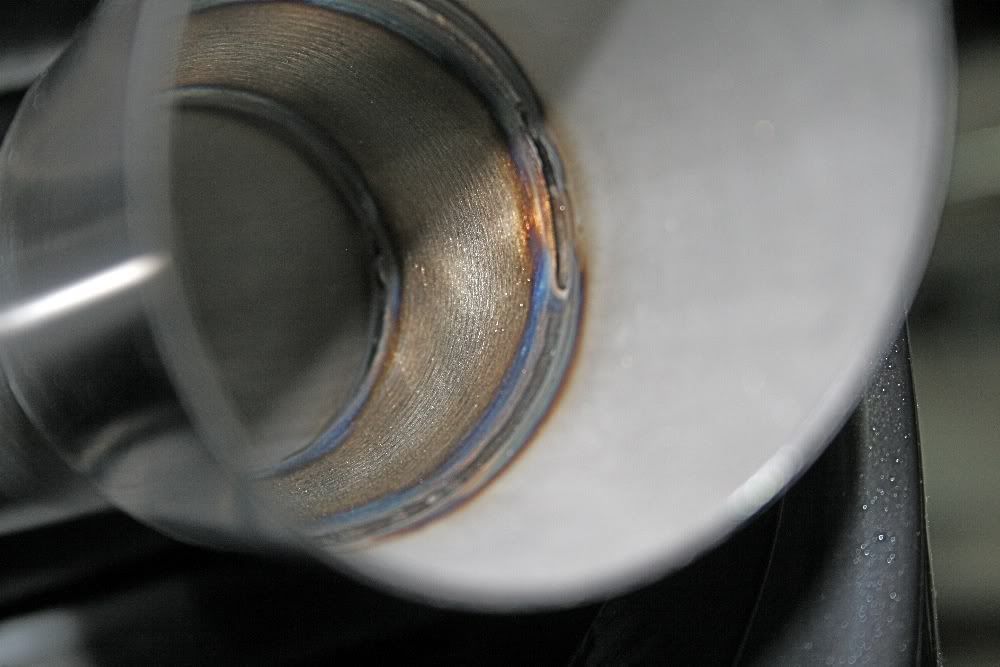

It pretty much looks like this at every weld on the inside of the pipes at the joints, hot and cold sides of the kit.

__________________

2014 1SS 1LE, bone stock for now.

|

|

|

|

|

|

#2 |

|

Fabricator

Drives: 2011 2SS Summit White Join Date: Jun 2011

Location: Langdon, AB

Posts: 505

|

Yes, under close inspection, alot of the work out there is less than optimal.

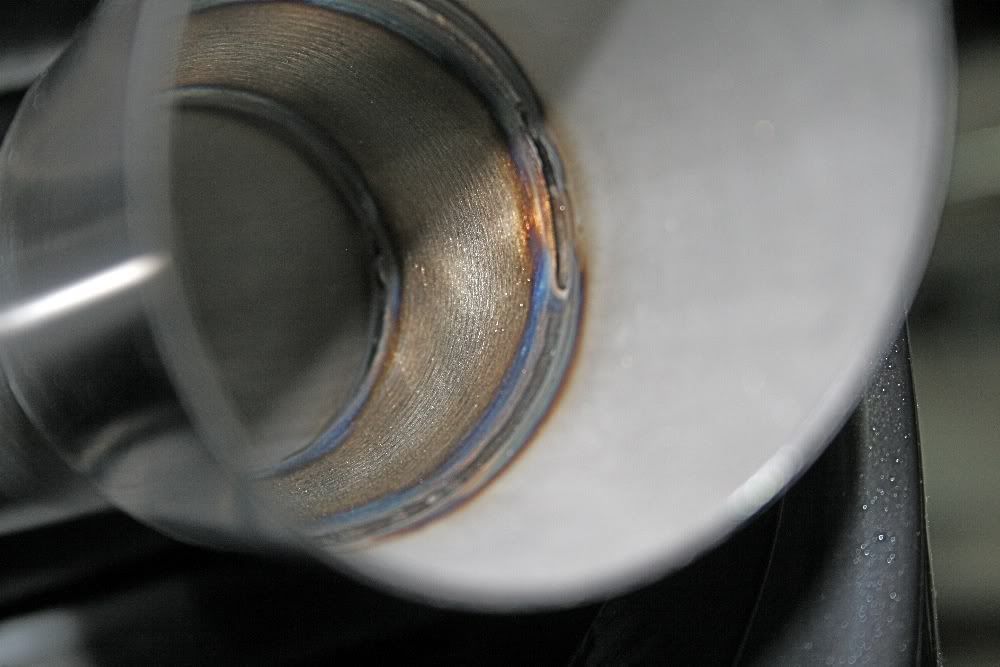

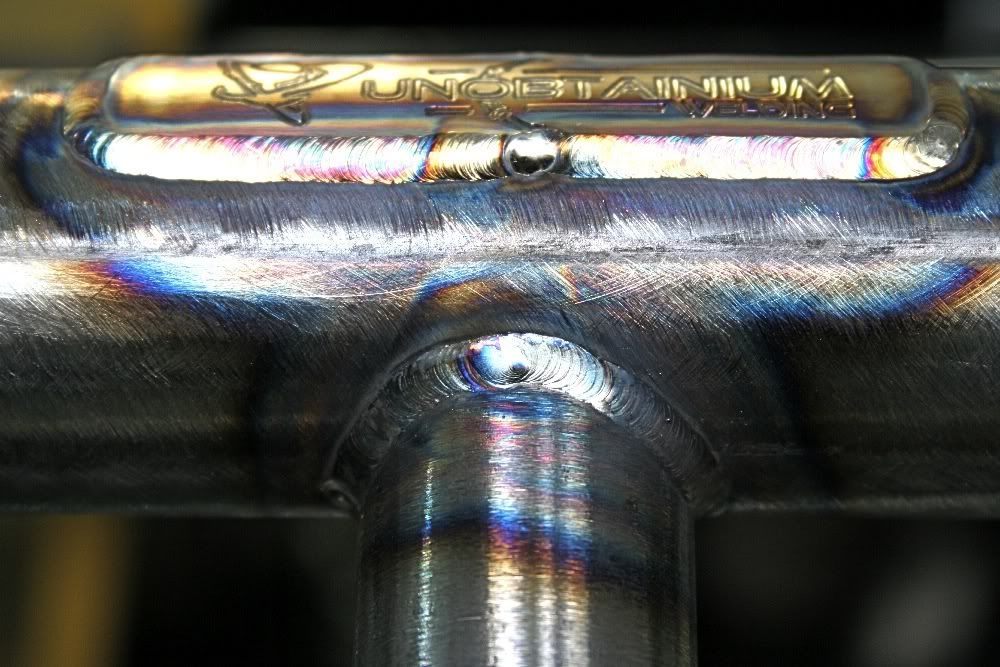

You have to get in there with a long carbide burr, and get off all of the loose burrs. The "slag" is actually oxidized metal from not purging the inside. It iwll not fall off. It can cause cracks and failure, but it's not loose. It costs time, money, and skill to do it right. That's why the majority of the stuff does not look like this inside...

__________________

Roto-fab CAI

Unobtainium Welding Exhaust ARH LT's 393whp L99 GPI VVT Turbo Cam-in |

|

|

|

|

|

#3 |

Drives: cars Join Date: May 2011

Location: Oversneeze

Posts: 4,542

|

Flex hone?

http://www.brushresearch.com/flex-hone-tool.php Dremel and flex shaft? How far in and how sharp of bends are we talking? |

|

|

|

|

|

#4 | |

Drives: 2012 45th Anniversary 2SS Join Date: Mar 2012

Location: West Chester Ohio

Posts: 1,845

|

Quote:

|

|

|

|

|

|

|

#5 |

|

Thats the problem, the long hot pipe on the left side of this picture is like that at every weld joint on the inside, same thing with the cross over pipe. I used a dremel and a carbide on the welds that I could reach but there is no tool, that I know of, that I can use for the rest of them.

__________________

2014 1SS 1LE, bone stock for now.

|

|

|

|

|

|

#6 |

Drives: cts-v Join Date: Dec 2011

Location: Mooresville, NC

Posts: 506

|

Any burrs, slag or shavings need to be cleaned out of that crossover pipe going to the turbo for sure. I know you have been through a lot already with this kit, but I would demand new pipes. If a burr on that crossover pipe breaks loose and takes out your brand new turbo, then what? Might as well toss some bird shot in there too before you fire it up...

The manufacturer of your kit says their new builder is much better and produces better products, well have them send you some of the new ones and send that junk back. |

|

|

|

|

|

#7 |

|

Fabricator

Drives: 2011 2SS Summit White Join Date: Jun 2011

Location: Langdon, AB

Posts: 505

|

I agree. Those should be replaced.

As a matter of fact, if they won't redo them, I'll redo them for you. Straight up. You send it to me and I'll do it right. Like in the pictures.

__________________

Roto-fab CAI

Unobtainium Welding Exhaust ARH LT's 393whp L99 GPI VVT Turbo Cam-in |

|

|

|

|

|

#8 |

|

Cory

Drives: 2010 Camaro 2SS/RS M6; Join Date: Nov 2009

Location: Carrollton, Tx

Posts: 298

|

Agreed, those should be replaced. But maybe it'd be better just to send them to unobtainium and let him work on it! This will be the first stuff I inspect on my kit when I get it.

|

|

|

|

|

|

#9 |

|

Damn bud, you can't catch a break!!!! Just when you think your good to go and ready to install, another problem appears. Still a nightmare that never seems to end

__________________

|

|

|

|

|

|

#10 |

|

Fabricator

Drives: 2011 2SS Summit White Join Date: Jun 2011

Location: Langdon, AB

Posts: 505

|

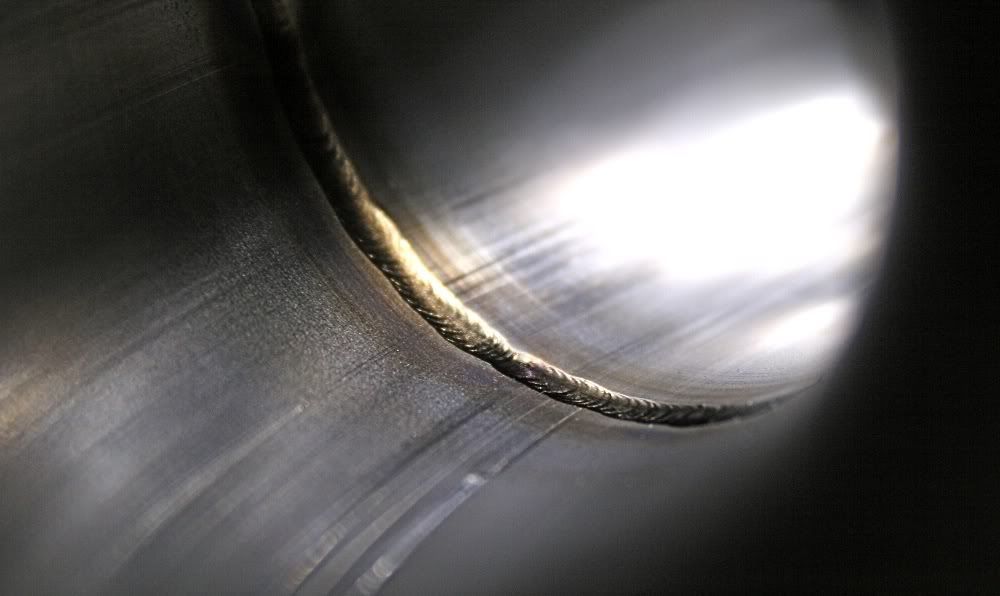

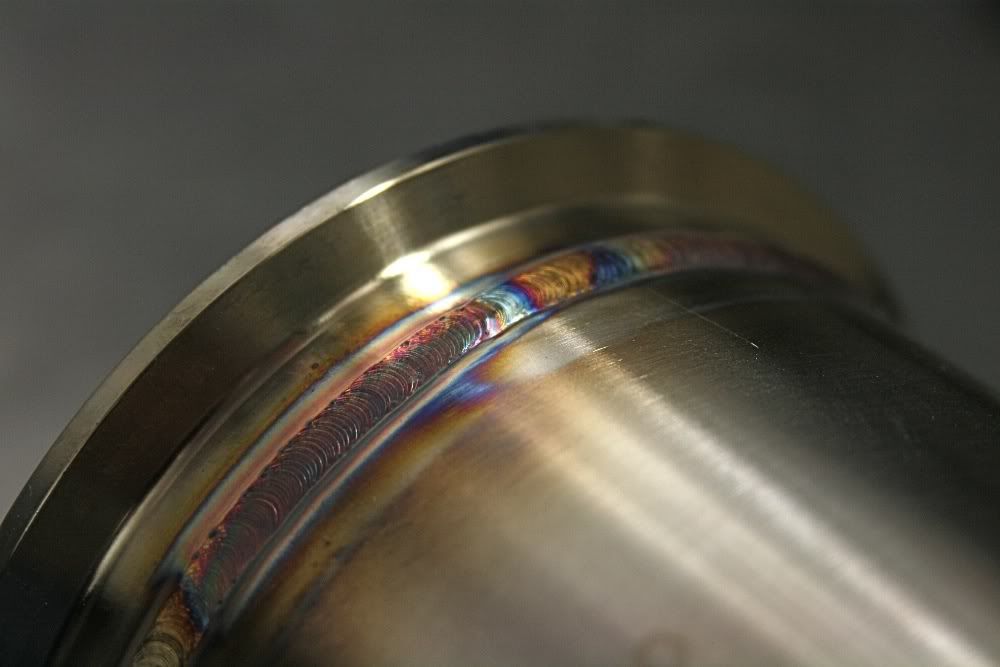

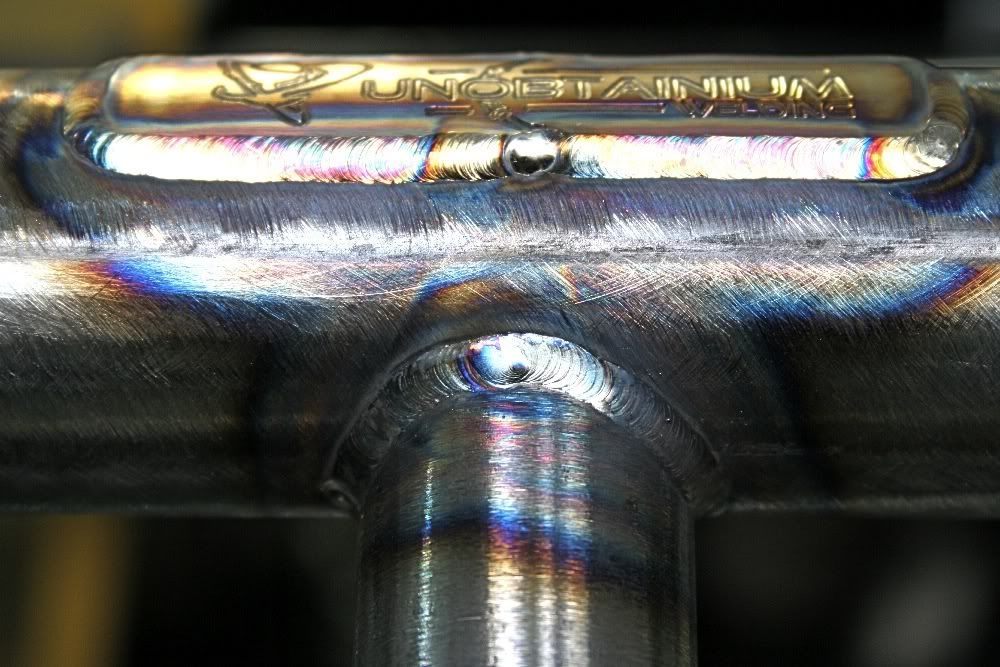

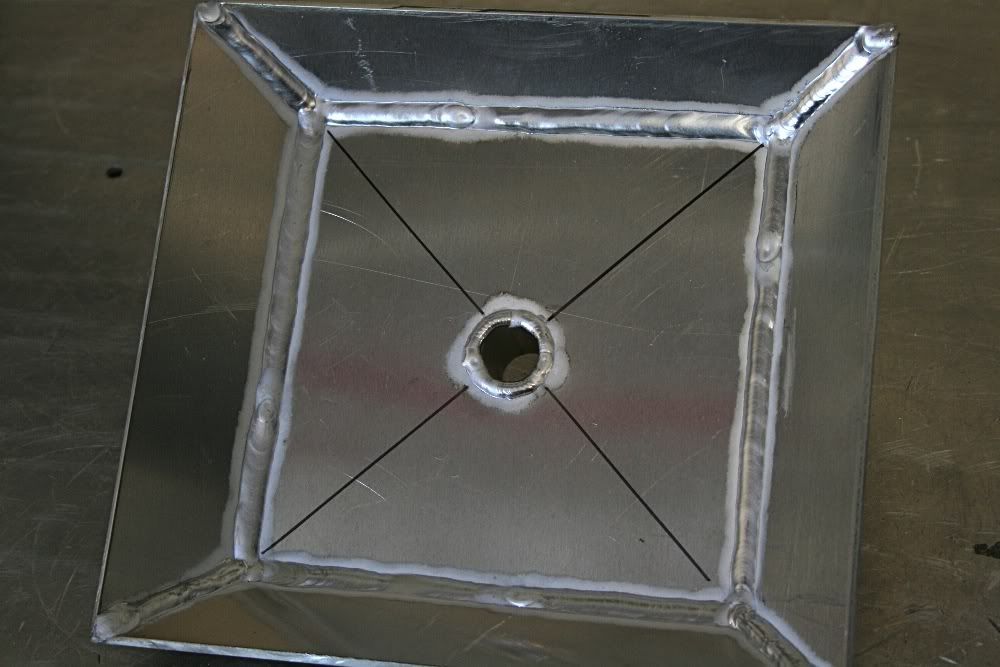

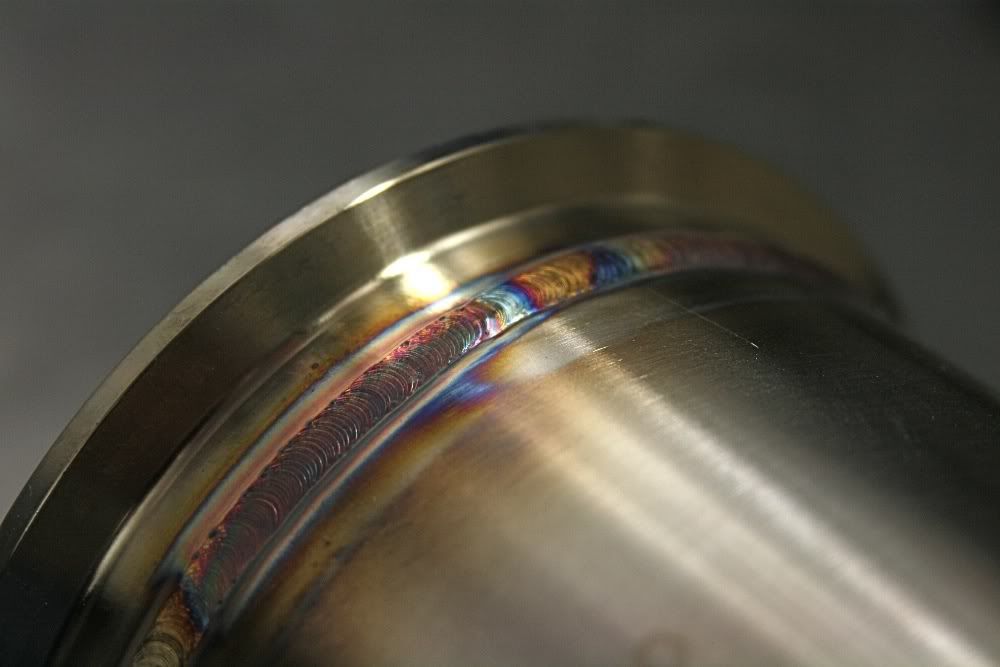

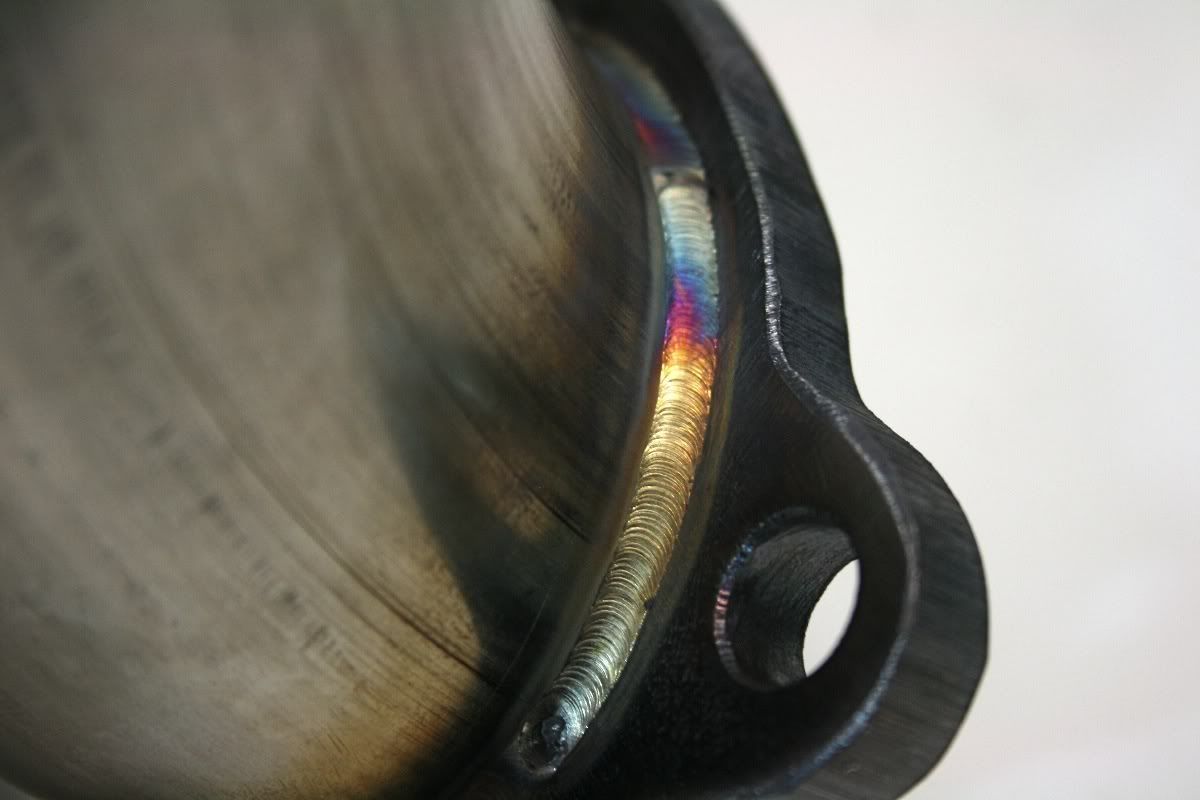

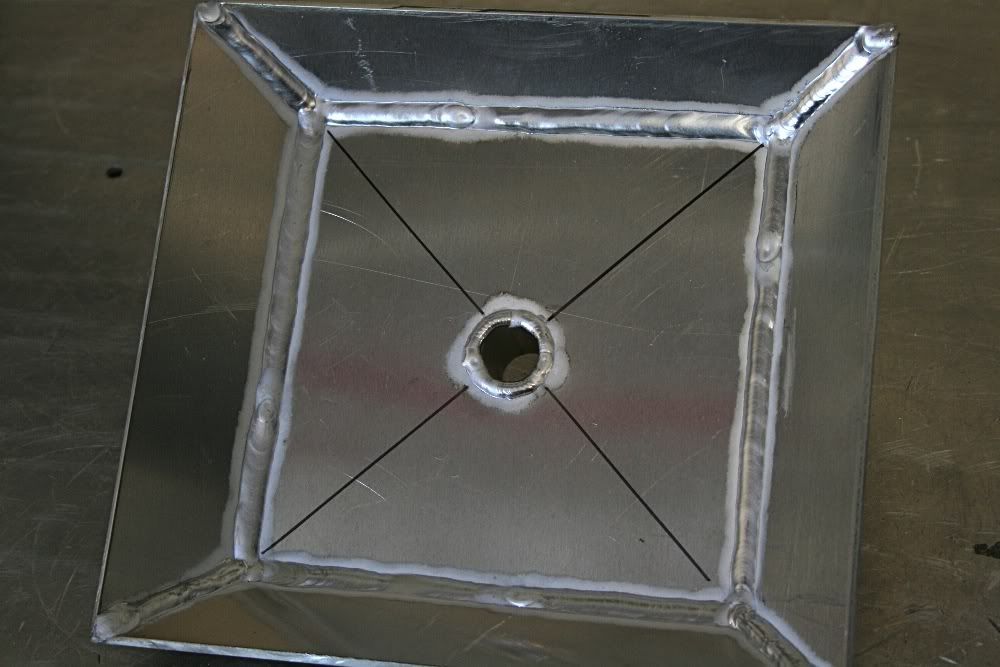

It's all about pride. Skill comes with time, and talent is there or it's not.

Pride though, is what makes us strive for excellence. Here are some pics of what my pride drives me to do.     These are tips on an F430, everything must be purged. So many guys cut corners in places like tips...   And hangers...Why just throw a hanger on when you can do it right like anything else. Make it something that if somebody ever sees it, they go "nice"  4130 weld on a super 7 rollbar   I weld inside all my custom end tanks and fuel cells, where possible. Why, because why not? Overkill is just enough.  This is what I found on a Ford GT supercar a friend brought in for me to work on. Where is the pride here?  This is more common than I would like to admit. I used to teach welding and try to instill this pride. I got to maybe 10%, maybe. Most just want the money and move on. You have to pay for quality, and you also have to demand it. If you are not willing to do either, then the results should not be a surprise. I happen to have heard that the guy doing that work was let go. I applaud the owners for doing that. It's a shame it didn't happen earlier. Bottom line, if somebody is not willing to post pics of their work and say "Look what I did.." then be afraid. I'm not offering to help because I need the work, I'm doing it to help a guy out. Either the manufacturer gets shamed into making it right, or I will. Demand better folks. Take a closer look next time when you hand over the visa number or the cash. It's up to you to make sure you are being treated fairly and you get what you asked and paid for.

__________________

Roto-fab CAI

Unobtainium Welding Exhaust ARH LT's 393whp L99 GPI VVT Turbo Cam-in |

|

|

|

|

|

#11 |

|

ROAD COURSE JUNKIE

|

[QUOTE=Unobtainium;5771013]It's all about pride. Skill comes with time, and talent is there or it's not.

Pride though, is what makes us strive for excellence. Here are some pics of what my pride drives me to do.     These are tips on an F430, everything must be purged. So many guys cut corners in places like tips...   And hangers...Why just throw a hanger on when you can do it right like anything else. Make it something that if somebody ever sees it, they go "nice"  4130 weld on a super 7 rollbar   I weld inside all my custom end tanks and fuel cells, where possible. Why, because why not? Overkill is just enough.  These are very sweet welds man!!

__________________

|

|

|

|

|

|

#12 |

Drives: 2SS/RS L99 BLACK Join Date: Apr 2010

Location: Franklin , MA

Posts: 6,696

|

It also appears that the op's pipes are mig welded not tig. There is a big difference

|

|

|

|

|

|

#13 | |

|

Fabricator

Drives: 2011 2SS Summit White Join Date: Jun 2011

Location: Langdon, AB

Posts: 505

|

Quote:

Never got that from the pics, but even scarier. OP, could you post a close-up of a few of the outside welds...

__________________

Roto-fab CAI

Unobtainium Welding Exhaust ARH LT's 393whp L99 GPI VVT Turbo Cam-in |

|

|

|

|

|

|

#14 |

Drives: 2SS/RS L99 BLACK Join Date: Apr 2010

Location: Franklin , MA

Posts: 6,696

|

|

|

|

|

|

|

|

|

|

|

|