You are browsing camaro5

|

|

|

#1 |

|

Does anyone make a vacuum pump for the PCV system for the camaro?

Right now I'm just running -10 off each valve cover to a over flow tank. Each valve cover has it's own tank.

__________________

MODS 6.0 forged iron block, TH400, B&M shifter, DSS axles & driveshaft, Viking / BMR suspension, Full custom fuel system with cell, Twin 76mm teriyaki tornados on 24lbs.

https://www.instagram.com/whoopa_ss/ |

|

|

|

|

|

#2 |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,381

|

A vacuum pump system is your absolute best solution, but you will not find one that will last more than a few thousand miles before needing new rotors, bearings, seals and shaft.

How your doing it now is greatly shortening engine life as your leaving most all of the damaging compounds in the crankcase to mix with the oil and cause premature wear and damage. NO form of Professional racing vents. The PCV system provides several functions critical to engine longevity and damage prevention, so when you defeat that your going back to pre 1960's technology. Look at our E2-X Ultra system. It emulates the functions of a belt driven vacuum pump by providing full time evacuation suction removing the damaging compounds as soon as the enter as blow-by, and uses 2 separate evacuation suction sources. The primary source provides evacuation during idle, light cruise, and deceleration, and a Venturi Effect generated suction to continue when in boost. This eliminates pressure from ever building to begin with so your piston rings can better maintain stability and your engine is protected. Let us know if you have any questions. We provide education so you understand all involved and just how it all works. We make different systems for different applications. Cheers! |

|

|

|

|

|

#3 | |

Drives: 2010 Camaro 2SS Join Date: Jun 2015

Location: Roy, Utah

Posts: 155

|

Quote:

I have a Moroso can that has a -12AN line going to each valve cover which I've drilled and tapped with -12AN fittings. The system terminates at the can and does not go back into the intake. This is what 100% of the pro guys do if they're not running a vacuum pump. Regards, Brady |

|

|

|

|

|

|

#4 |

Drives: 2013 1SS 1LE Join Date: Jun 2016

Location: Ixonia wi

Posts: 1,456

|

Same here... Vacuum is ideal, but sucking that crap back into the intake is terrible.

__________________

2013 1le- Katech 416 short block, TSP custom grind cam, LOD intake, cnc heads by F.ED., Nick William's 102mm T.B., CORN fed, Pedders coilovers. Performance street alingnment by Justin at Lake Country Alignment and dyno tune by Late Model Throttle.

603 h.p. 495 ft lbs tq. |

|

|

|

|

|

#5 |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,381

|

Hi BradySS,

I would be interested in which "Pro Guys" you think are doing this? Our Tech Support team is full of Professional racers and engine builders and confirm this. The only way is with a vacuum pump pulling suction and then exiting into a breather can like you describe. Can you show any type? We crew on Formula cars as well and none vent like your describing, all use either a belt driven standalone vacuum pump as the OP asked about, or a vacuum module in the external dry sump pump assembly. See by eliminating evacuation, and venting pressure, your leaving almost all of the damaging compounds to settle and contaminate the engine oil along with the pressure fighting the pistons on the down stroke. Use of a 95% effective catchcan system, like our Elite E2-X is not allowing oil or any of the other compounds to enter the intake air charge. Here is a Moroso vacuum pump and the catch tank you plumb into the exit of the pump:    Aerospace Components:  To not use a vacuum pump and just run hoses from each valve cover releases pressure AFTER it builds and no evacuation takes place at all. Your allowing excessive premature wear over time by not evacuating these from the crankcase prior to them settling. Then as your not pulling full time suction, you run into ring flutter issues that wear the ring leading edges as well as small divots over time in the cylinder walls. What your in essence doing is what was the industry standard from early 1900's to the mid 1960's. Off road and racing still vented until the 1980's. Since then, only those that do not understand just use assumptions. And there is so much more to consider. The PCV/Crankcase evacuation systems provide several critical functions and only one is pollution control related. Look at GZ as a vacuum pump that some use on the street as well. I hope this makes sense. |

|

|

|

|

|

#6 |

Drives: 2010 Camaro 2SS Join Date: Jun 2015

Location: Roy, Utah

Posts: 155

|

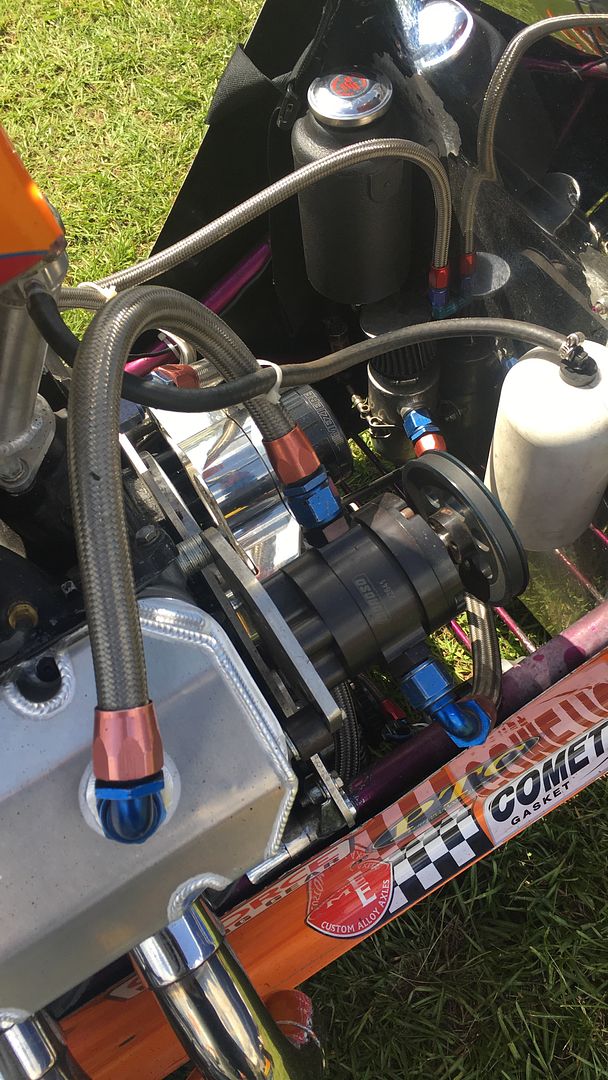

Thanks for the reply.

I agree a dedicated vacuum pump is the best and I'm not arguing about that at all. I just think the way the original poster has his setup is fine. The proguys I'm talking about well that's tons of people in NMRA, NMCA and many other pro forms of drag racing. There's pages and pages of information regarding this over at yellowbullet.com. Every single person running serious times over there is either running a pump, lines going to the headers or the setup I'm describing and running. I designed mine just like the COPO Camaros. I bought the COPO build book and that's exactly how GM does it. Ford designed the Cobra Jets exactly the same way as well. Never seen a serious car run a catch can. I included a few pictures below giving examples but there's pages of them over at the site I mentioned above. One of these pictures is a COPO Regards, Brady Last edited by BradySS; 06-17-2018 at 07:43 PM. Reason: Inclusion |

|

|

|

|

|

#7 |

Drives: 12 camaro ss, 72 chevelle, 91camaro Join Date: Dec 2013

Location: findlay,oh

Posts: 2,069

|

my build isn't finished yet but I have a 12 an fitting on each valve cover going to an open catch can

__________________

12 camaro ss 427lsx, th400, f310 heads, crower shaft mounts, gpi specd solid roller, shearerfab 2k hp a/w, twin bullseye 88mm turbos, hughes pro ssx bolt together converter, holley dominator, 8.50 cert, backhalf, Ford 9", 33x17x16 tires, c16 fuel

|

|

|

|

|

|

#8 |

|

Angewendet Ingenieur

Drives: 14 Camaro ZL1 Join Date: Apr 2015

Location: USA

Posts: 401

|

I have bought the Moroso also and considering this as well. I think it might be stretched to use the word “compounds” but of course I keep my oil changed more than normal. Interesting that COPO is setup like this, perhaps I will give SM a call and get his opinion.

__________________

LQ9, Iron Block, Forged internals, 408CI, Jannetty custom cam, TS short block, Whipple, Hardened Jackshaft, PRC 260, 2X3 Dynatech Full Competition, HF Cats, CAI, NW 103, Chee, ID 1300, COPO Breather, MSD, Fore Dual Pump, ultratorque, E85, dual Meth, True Trac, 3:45, 1500hp axle-shafts, DSS CF, BMR, custom Pearl/Candy paint by Jaidah. |

|

|

|

|

|

#9 | |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,381

|

Brady and ProTuned, NMCA and NMRA are NOT pro racing, these are amateur race series for the tuners and those that race outside of the Professional NHRA/IHRA classes. The COPO is not a Pro class car either but have to run the class rules. There is not a single Professional form of Motorsports that does this. But the sportsman classes like Stock and Superstock as well as local stock cars with claimer engines must run the rules that dictate from the early 1960's. Changing oil after each race is how they avoid damage and premature wear. But think of what doing this does to the engine. As there is no evacuation and flushing taking place, most all of the damaging water, acids, raw fuel, and abrasive particulate matter remains in the crankcase contaminating the oil. On the street, most don't change their oil every outing like those racing. But the biggest immediate issue is power. Most spend thousands to make good power, but then skimp on crankcase evacuation which is critical to proper ring seal and removing the pressure the pistons fight on the downstroke. Watch this video. First pull is venting, second pull is pulling suction: So, I see confusion as to Professional class racing and the amateur racing like NMCA and NMRA and more small series like this. And also what is best vs what is allowed by class rules. Good discussion so ask more questions to understand all that is involved with this. |

|

|

|

|

|

|

#10 |

|

Angewendet Ingenieur

Drives: 14 Camaro ZL1 Join Date: Apr 2015

Location: USA

Posts: 401

|

Thank you for your comments Elite. From a wear prospective using comments such as “compounds” which are derived from oil (other than gas or water) one really needs to understand modern oil compositions including “prioritary chemicals” that producers use in modern oils that vary from one producer over the next as well as the various refinement processes involved in more detail. These all vary from one producer over the next. Over the counter testing will not disclose all compositions. SRU’s are used by many producers (as a result of mandates) that remove sulfur by as much as 98% in modern day engine oils. Without this removal the potential for acid formation increases dramatically. Personally I don’t want these introduced in the combustion processes in any form.

Speaking of “Street” and “Pro Racing” different blends and setups made for such activity should be considered. For me the best is just to select the proper oil, keep it changed, always keep good filters, all under the proper temperatures. There’s a reason why there are qualified petroleum and chemical engineers... |

|

|

|

|

|

#11 |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,381

|

Pr-Tuned,

Good points, and this is why we worked for over 2 years in conjunction with one of the largest most respected lubrication labs in the World as they were looking to solve fuel dilution and other issues. Changing oil every outing gets expensive as our street system emulates this but with no vacuum pump. We use IM vacuum for non boost or idle, light cruise, and deceleration suction, and the suction/vacuum developed via the Venturi Effect for WOT and in boost evacuation so there is always full time evacuation pulled and these contaminants (Mainly water, acids, raw fuel, and abrasive particulate matter consisting of soot/ash/carbon. They did this test with a fleet of new GDI vehicles and the turbo ones were the worst offenders. Of course no intake valve coking occurs on a port injection engine, but the rest is all valid. Another additive or formulation is to combat LSPI (Low SPeed PreIgnition) as several oil brands now have moved to as well. Read this summary: Final results of 2 year study Here is a brief summary of what was documented in the 2 year testing by one of the Worlds largest Lubrication companies: The XXXXXX system was tested on the most severe engine on the road toady as far as GDI related issues. The testing was performed on a fleet of new vehicles including GM and others, but they only focused on the results of the Ford Ecoboost engines as they experience the most severe GDI related effects. First, here is how the testing was performed. Each vehicle has been run through proper break-in and driven over 10k miles to eliminate ring seating variance, etc. Then the vehicle would be run for app 5-6k miles on their premium full synthetic oil and a sample drawn...this is without our system installed. Then, our system is installed on that same oil fill, no oil change, and then run another 4-5k miles and another sample drawn and at that time oil is drained and changed. Here are some examples on just viscosity and fuel dilution: Miles on vehicle: 55060 Ford 3.5L Ecoboost Miles on oil when sample drawn: 5,943 Fuel dilution: 5.6% Viscosity @40*C: 45.71 Viscosity @100*C: 8.76 (Now, vehicle is driven and sample drawn below) Miles on oil when sample drawn: 9,411 Fuel dilution: 3.86% Viscosity @40*C: 46.98 Viscosity @100*C: 8.82 (Even AFTER saturation well above the industry 5% threshold where oil is considered "condemned" or no longer able to protect the engine our system was able to not only prevent further fuel dilution and viscosity degradation, but actually IMPROVED each taking the oil that was no longer usable and extending it's ability to protect far longer. Now, that was the least dramatic result....some were as high as fuel dilution levels of 7% to above 12% by 5k miles (cold start enrichment in cool/cold conditions adds to dilution far quicker) and we were able to bring those levels down even more dramatically, in some cases by as much as 50% less after a few thousand miles WITH our system installed. Other benefits documented: Average fuel economy increases of 1-3 MPG due to a cleaner burn with the contaminants removed from the PCV vapors as more energy is released with just air and fuel present during the combustion process. This also shows a significant reduction in knock retard as pre-ignition is reduced and combined with a cleaner burn in the combustion chamber, reduces emissions as well as improves fuel economy. As our system converts the PCV system to full time evacuation and flushing VS part time as the OEM systems come and retains a closed emissions compliant system. This prevents the stagnant periods of operation when the contaminants and combustion by-products that enter as blow-by and are the primary source of oil contamination and our system greatly reduces this by removing these at all times the engine is running utilizing 2 separate evacuation suction sources, the intake manifold vacuum for when reversion pluses are not canceling it out (during acceleration or hard operation no evacuation suction is present stock), and using the Venturi effect when accelerating or running high RPM/throttle. On GDI engines (most all Automakers are now 100% GDI) we have the additional benefit of reducing the intake valve coking issue by as much as 85% (we cannot eliminate all as these engines use variable valve events to allow back filling of exhaust gasses back into the port behind the valves to be re-burnt emulating the outdated EGR system/valves of old. To summarize, the benefits: Engine life extended to 2-3 times expected life w.out the system installed. Fuel economy increase of 1-3 MPG average. Extended oil drain intervals allowing from 50% to 100% longer use of oil reducing pollution from improperly disposed of drain oil. Reduced tailpipe emissions. As we remove most of the compounds causing a incomplete burn in the combustion process reducing the amount of emissions. Reduction of intake valve deposits by as much as 85%. The downside is these MUST be drained and the contents collected disposed of properly as with any drain oil. every 5k miles as a rule (will vary from engine to engine depending on state of piston ring seal to cylinder walls). We do have a system that never needs to be emptied or service for in excess of 100k miles, but not released yet that could be retrofitted at a later date. What is in the contents of the system that are removed from the engine crankcase vapors? Here is a sample after a 2400 mile drain after being spun in a centrifuge to separate all for analysis: 70% was acidic water (the sulfuric acid produced during the combustion process cannot be separated from the water). 23% was raw fuel (GDI engines introduce fuel at well over 2,000 PSI and this pushes many times the amount past the rings of old port injection systems that operated at 45-50 PSI) and only 7% was actual oil, and it is saturated with abrasive particulate matter. This other wise would have remained in the crankcase mixing with and contaminating the engine oil, and also contaminating the intake air charge reducing the over efficiency of the engines combustion process. Now they also purchased several GM based vehicles as well, but they summarized on an Ecoboost. Also, here is what our system traps (from the same lab after spun in the centrifuge):  70% water and acids (acid cannot be separated after mixing) 23% raw fuel 7% oil saturated with abrasive particulate matter. We guarantee our proper system to stop 95% plus of what enters, and to also flush and remove the majority of the contaminants as soon as they enter prior to settling and mixing with the oil. Remember, a good oil filter is only trapping down to 10-12 microns where 70% plus of all internal wear is caused by particluate matter smaller than 8 microns. We do work directly with the Automotive Industry as well as lubrication labs so we can always back up our claims as you can see here with these renderings done by the head of engineering for Turbonetics, and his endorsement that these are the ONLY systems they have tested that addressed all of the common issues turbo build experience. Good input, lets discuss more if your not follow this 100%. Cheers! |

|

|

|

|

|

#12 |

|

Angewendet Ingenieur

Drives: 14 Camaro ZL1 Join Date: Apr 2015

Location: USA

Posts: 401

|

Enjoy your your reading and it offers points to consider. I can state with ease oil labs are not detecting everything. Processing takes on many steps given many considerations from geo-physical, regional, and reservoir structure (to name a few) that optimize production with quality and value. Some oils cost more to produce than others, some oils are better quality than others. Processed oils are not the same, and testing the oils with identical processes will offer different results. I do not agree that standard oil analysis captures everything. I agree the cleaner the air charge and oil results in less wear on mechanical parts. This is the driver for me in a PD setting, provides my rational to avoid recirculation and not a primary goal of HP gains. This I guess falls back on expectations of the individual. Could it be possible changing oil more often may trump costs in terms of extended engine life with less wear? A subject I think would make a great PHD project. Thanks again!

__________________

LQ9, Iron Block, Forged internals, 408CI, Jannetty custom cam, TS short block, Whipple, Hardened Jackshaft, PRC 260, 2X3 Dynatech Full Competition, HF Cats, CAI, NW 103, Chee, ID 1300, COPO Breather, MSD, Fore Dual Pump, ultratorque, E85, dual Meth, True Trac, 3:45, 1500hp axle-shafts, DSS CF, BMR, custom Pearl/Candy paint by Jaidah. |

|

|

|

|

|

#13 |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,381

|

Excellent to run into someone that understands oil formulations! And also, your correct on most oil analysis. You cannot get an accurate fuel dilution sample unless it is drawn immediately at shutdown via the oil dipstick tube and immediately seal the container as it flashes off so rapidly. Something 99% I see assume they are fine. Then the averages given are generally from the same family of engine, so what may be excessive in a port injection engine would be considered "within range" of the other GDI family. So that is misleading.

TBN is the acid level, and that same sample in the summary the TBN alsowas substantially better than without. The system in the test provides full time evacuation instead of only at idle, light cruise, and deceleration due to the reversion pulses generated by valve overlap that cancels IM vacuum when accelerating or at WOT. That is a great benefit over a simple "catchcan". Email me direct at: Tech@EliteEngineeringUSA.com I have more to share in private. Thanks! |

|

|

|

|

|

#14 |

|

Angewendet Ingenieur

Drives: 14 Camaro ZL1 Join Date: Apr 2015

Location: USA

Posts: 401

|

EI thanks and will do!

|

|

|

|

|

|

|

|

|

| Thread Tools | |

|

|