You are browsing camaro5

|

|

|

#1 |

Drives: 2012 Camaro SS Join Date: Feb 2017

Location: Dubai-UAE

Posts: 35

|

Oil catch can recommendations

Hi

Which oil catch can do you recommend for 2012 L99 A/T Car is a daily driver with a few circuit tracks yearly, will be adding CAI, headers and camshaft I prefer those from TSP or summit but I'm open to other suggestions if it that good Thanks in advance |

|

|

|

|

|

#2 |

Drives: 2010 Camaro SS/RS Join Date: Mar 2014

Location: somewhere in MD

Posts: 4,883

|

I've had a Mike Norris catch can on my car since I've had it. Works great and inexpensive compared to others.

__________________

2010 2SS/RS

Z/28 intake, NW, FAST 102, speed engineering LT's, some exhaust, ATI -10% pulley, GM flex fuel injectors, DSX flex fuel sensor, MGW shifter, HP Tuners, some suspension work, stickers and a little weight loss. 12.63 @113.53 |

|

|

|

|

|

#3 |

Drives: 2015 Camaro SS Join Date: Sep 2011

Location: Jacksonville, Fl

Posts: 713

|

Elite Engineering...

Removed my intake manifold after 13k for ported heads and I had no oil build up inside

__________________

2015 Camaro 2SS Cam/Heads/FBO 498/447 SAE |

|

|

|

|

|

#4 |

|

Svt lol

Drives: 2011 ss inferno orange blown Join Date: Jan 2012

Location: Topeka

Posts: 2,312

|

Oh god please don't open this can of worms again.

__________________

plasti dip is not a mod.......and a cold air intake doesn't make you fast!

|

|

|

|

|

|

#5 |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,382

|

The Catch Can is really a misnomer as a "catchcan" is a container to catch liquid that over flows. When shopping for an air/oil separation system you will find everything under the sun, and 99% of them will be nothing more than an empty container with little or no internal components that effectively separate and trap the oil mist and other compounds you do not want as part of the intake air charge that reaches the combustion chamber.

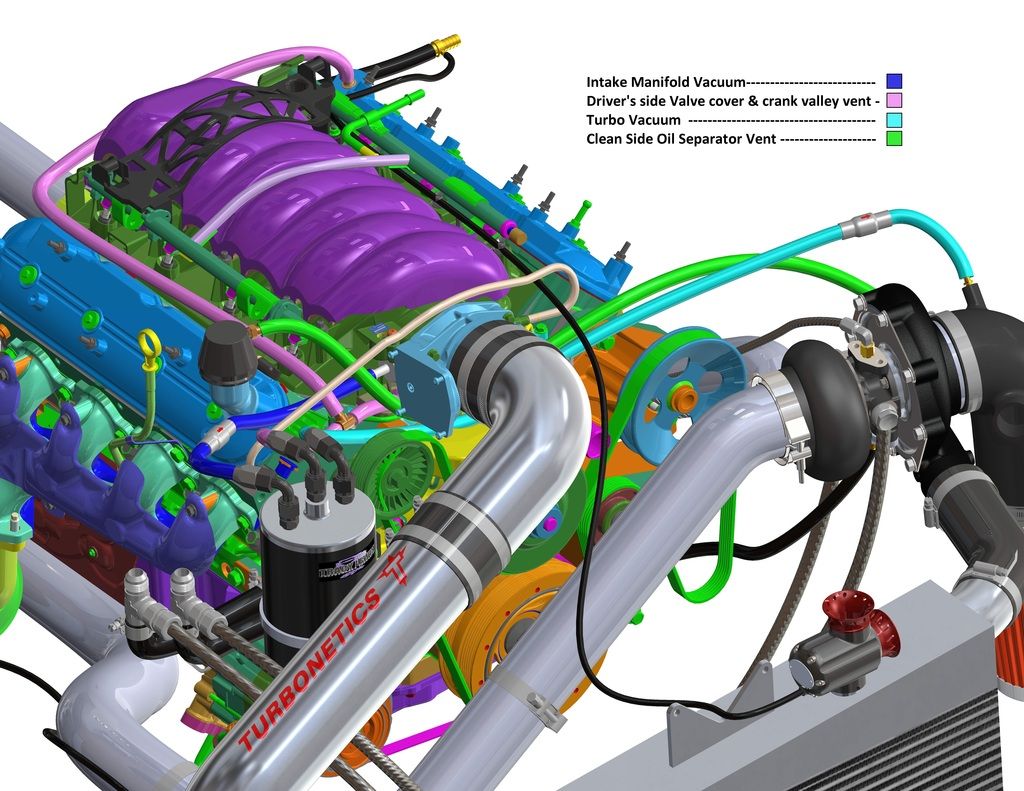

Even some of the most popular brands only trap from 15-30% of these, so choosing one that is effective and does what it is used for is hard with all claiming to be the "best". The Elite E2 and E2-X Catch Cans are designed to trap 95% plus and are at the very top of the most effective on the market period. Our Base Elite Catch Caan is a good choice also for the port injection engines that are left basically stock and for the price is probably the most effective of any of the lower priced cans and as port injection engines can tolerate some ingestion unlike the GDI engines that cannot. The E2 and E2-X Catch Cans are great choices for a modified port injection engine and allows the option to use dual outlets for full time evacuation. The E2-X line is very effective, and the kit comes standard with what is optional with most, billet check valves (for the dual valve), all AN fittings, 1/4 turn ball valve drain valve, and more. Here is a summary of a 2 year study on this design for those that are interested in just how these benefit today's GDI engines: Final results of 2 year study "Here is a brief summary of what was documented in the 2 year testing by one of the Worlds largest Lubrication companies: The RX system (same design as the E2-X) was tested on the most severe engine on the road toady as far as GDI related issues. The testing was performed on a fleet of new vehicles including GM and others, but they only focused on the results of the Ford Ecoboost engines as they experience the most severe GDI related effects. First, here is how the testing was performed. Each vehicle has been run through proper break-in and driven over 10k miles to eliminate ring seating variance, etc. Then the vehicle would be run for app 5-6k miles on their premium full synthetic oil and a sample drawn...this is without our system installed. Then, our system is installed on that same oil fill, no oil change, and then run another 4-5k miles and another sample drawn and at that time oil is drained and changed. Here are some examples on just viscosity and fuel dilution: Miles on vehicle: 55060 Ford 3.5L Ecoboost Miles on oil when sample drawn: 5,943 Fuel dilution: 5.6% Viscosity @40*C: 45.71 Viscosity @100*C: 8.76 (Now, vehicle is driven and sample drawn below) Miles on oil when sample drawn: 9,411 Fuel dilution: 3.86% Viscosity @40*C: 46.98 Viscosity @100*C: 8.82 (Even AFTER saturation well above the industry 5% threshold where oil is considered "condemned" or no longer able to protect the engine our system was able to not only prevent further fuel dilution and viscosity degradation, but actually IMPROVED each taking the oil that was no longer usable and extending it's ability to protect far longer. Now, that was the least dramatic result....some were as high as fuel dilution levels of 7% to above 12% by 5k miles (cold start enrichment in cool/cold conditions adds to dilution far quicker) and we were able to bring those levels down even more dramatically, in some cases by as much as 50% less after a few thousand miles WITH our system installed. Other benefits documented: Average fuel economy increases of 1-3 MPG due to a cleaner burn with the contaminants removed from the PCV vapors as more energy is released with just air and fuel present during the combustion process. This also shows a significant reduction in knock retard as pre-ignition is reduced and combined with a cleaner burn in the combustion chamber, reduces emissions as well as improves fuel economy. As our system converts the PCV system to full time evacuation and flushing VS part time as the OEM systems come and retains a closed emissions compliant system. This prevents the stagnant periods of operation when the contaminants and combustion by-products that enter as blow-by and are the primary source of oil contamination and our system greatly reduces this by removing these at all times the engine is running utilizing 2 separate evacuation suction sources, the intake manifold vacuum for when reversion pluses are not canceling it out (during acceleration or hard operation no evacuation suction is present stock), and using the Venturi effect when accelerating or running high RPM/throttle. On GDI engines (most all Automakers are now 100% GDI) we have the additional benefit of reducing the intake valve coking issue by as much as 85% (we cannot eliminate all as these engines use variable valve events to allow back filling of exhaust gasses back into the port behind the valves to be re-burnt emulating the outdated EGR system/valves of old. To summarize, the benefits: Engine life extended to 2-3 times expected life w.out the system installed. Fuel economy increase of 1-3 MPG average. Extended oil drain intervals allowing from 50% to 100% longer use of oil reducing pollution from improperly disposed of drain oil. Reduced tailpipe emissions. As we remove most of the compounds causing a incomplete burn in the combustion process reducing the amount of emissions. Reduction of intake valve deposits by as much as 85%. The downside is these MUST be drained and the contents collected disposed of properly as with any drain oil. every 5k miles as a rule (will vary from engine to engine depending on state of piston ring seal to cylinder walls). We do have a system that never needs to be emptied or service for in excess of 100k miles, but not released yet that could be retrofitted at a later date. What is in the contents of the system that are removed from the engine crankcase vapors? Here is a sample after a 2400 mile drain after being spun in a centrifuge to separate all for analysis: 70% was acidic water (the sulfuric acid produced during the combustion process cannot be separated from the water). 23% was raw fuel (GDI engines introduce fuel at well over 2,000 PSI and this pushes many times the amount past the rings of old port injection systems that operated at 45-50%) and only 7% was actual oil, and it is saturated with abrasive particulate matter. This other wise would have remained in the crankcase mixing with and contaminating the engine oil, and also contaminating the intake air charge reducing the over efficiency of the engines combustion process. On Fleet applications, depending on miles driven the fuel economy and oil drain extensions give a ROI in app 6.7 months average. As a whole, these could drastically reduce overall emissions as well as tremendous savings on fuel cost and usage." And to see an example of the disparity between cans effectiveness, this test can be performed by anyone to see first hand: https://www.youtube.com/watch?v=IZYYdnwIEX0&t=1321s And this for installation ease: https://www.youtube.com/watch?v=ai-s5azMLsU Our Clean-Side Separator (CSS) is a critical part to any installation as it addresses the 2nd point of ingestion better than the GM plastic unit included with the 1LE. Any questions of a technical nature, please ask and were here to help. And finally, Trob, we all know your opinion (ignoring the facts) and your constant interference with these threads is getting old. None of us ever interfere with your threads and it would be great to see the same courtesy when others are looking for accurate guidance. Do it once, Do it right, Elite Engineering USA |

|

|

|

|

|

#6 | |

Drives: 2017 Mosaic Bk ZL1 M6 Join Date: Jul 2009

Location: South of Raleigh, NC

Posts: 9,477

|

Quote:

__________________

|

|

|

|

|

|

|

#7 |

|

"Old School"

Drives: 2010 2SS L99 Join Date: Apr 2015

Location: Sherrills Ford, NC

Posts: 1,295

|

I like the way the bottom of the can unscrews on the original Elite Engineering Can. I just put one on and I may upgrade to the E2 eventually.

|

|

|

|

|

|

#8 |

Drives: camaro ss\rs Join Date: Jun 2014

Location: Italia

Posts: 755

|

last year i wanted to add a catch can and i was unsure about what to buy. I ended up with the mighty mouse. I couldn't be happier. David Knows his stuff and he told me how to modify the pcv route. i ended up with a much better idle

__________________

2014 camaro SS Whipple powered ,3.750 pulley,ID850, CAI,Flowmaster American Thunder exhaust,MGW racing shifter,Bo White ported tb,MightyMouse Catch Can,Vitesse throttle controller,GM 3.91 rear end, Dynatech longtube haders, BTR Pd cam,Fluidampr stock pulley,ZL1 fuel pump and ADM fpcm, Phastek scoop and fluid thank relocation Bmr Motor mount . Tuned by Mastuning

|

|

|

|

|

|

#9 |

Drives: Savitar; The 500rwhp N/A Monster! Join Date: Aug 2016

Location: Middletown, Ohio

Posts: 2,914

|

+1 on Elite Engineering.

__________________

*SOLD*504HP/433TQ | Night Fury cammed Cold Air Inductions intake Bo White ported TB Speed Engineering 1 7/8 longtubes NPP catback QTP low profile cutouts Powerbond 25% UDP 3.73 gears JRE scoop ZL1 grille R1 Concepts drilled/slotted rotors built/tuned by Weapon X Motorsports

|

|

|

|

|

|

#10 | |

|

Svt lol

Drives: 2011 ss inferno orange blown Join Date: Jan 2012

Location: Topeka

Posts: 2,312

|

Quote:

__________________

plasti dip is not a mod.......and a cold air intake doesn't make you fast!

|

|

|

|

|

|

|

#11 |

|

old school chevy rodder

Drives: 2013 2SS/RS Manual,DM exhaust,CRT Join Date: Jul 2012

Location: Oregon

Posts: 5,587

|

A Elite............................................. .................................

Not a cheap POS 40$ Chinese thing on Ebay with vinyl tubing waiting to get hard and fall off............

__________________

2021 Wild Cherry ZL1 A10, Sunroof, Data, Carbon, Nav, RotoFab Dry CAI, Elite x2, Borla ATK, Driveshaft shop 2021 Wild Cherry ZL1 A10, Sunroof, Data, Carbon, Nav, RotoFab Dry CAI, Elite x2, Borla ATK, Driveshaft shop |

|

|

|

|

|

#12 |

Drives: 2014 SS 1LE Join Date: Apr 2014

Location: United States

Posts: 660

|

If you are N/A elite can is fine, but I think the consensus is if boosted go Mighty Mouse.

__________________

|

|

|

|

|

|

#13 |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,382

|

For the record, we perform all the effectiveness tests here, in-house before we ever offer the "Catchcan Challenge" in public. However, we know it holds far more credibility if someone independent does the testing, and we have provided the Elite Catch Can at no charge. We challenge ANY Catch Can for effectiveness test as no other design comes close.

Jeff65, To give a better understanding of the Elite E2-X series...especially the Ultra for forced induction. It is larger in capacity than MM, it traps 95% plus of the oil and other compounds you don't want ingested, vs a fraction of that, and it pulls evacuation suction at all times, boost or no boost VS only non boost with the MM, and then if there is ever excessive blow-by that would build pressure, it immediately vents it with no valve to open, but not into your engine compartment but into the main air filter with the oil scrubbed from it. No comparison. Let us know if your not following any of this...were happy to go into more detail as needed. The E2-Xline includes a billet cleanside separator unit with internal separation chamber and uses 2 separate evacuation suction sources.    |

|

|

|

|

|

|

|

|

|

|