You are browsing camaro5

|

|

|

#1 |

Drives: 2011 2SS Join Date: Jan 2014

Location: PA

Posts: 83

|

3 broken belts and tensioner

2011 LS3 with an LSA conversion. 644rwhp. I have now broken my 3rd belt at the track Friday night when hitting 3rd gear and the stock lsa tensioner pulley. I have a 2.5 adm pulley and the recommended belt size of K061005 but it's super tight with very little play when you install the belt and release the tensioner. My thoughts are that this recommended belt size is too small and the stock tensioner can't handle the 12lbs of boost. Any thoughts or suggestions?

|

|

|

|

|

|

#2 |

Drives: 2018 ZL1 1LE - HBM, PDR Join Date: Jun 2017

Location: Rescue, CA

Posts: 324

|

You may be on to something with the belt being too short. I broke a belt following a pulley upgrade and concluded that the belt was too small in which it placed the tensioner at the compressed limit. Because the tensioner was not centered in the throw (mid point between min and max), there was no room for the tensioner to cycle through the range when I would get hard on the throttle and then off the throttle.

I did my best to give the breakage a forensics review to the best of my ability and this is what I concluded. Here is the thread if interested in more details. https://www.camaro6.com/forums/showthread.php?t=523261 If you determine root cause, please share in your thread as inquiring minds would like to know. Good luck. Subscribed... Sent from my SM-G950U using Tapatalk

__________________

JRE Tuned (HPTuners) | 15% OD (9.17" crank pulley) | TVS2300 Maggie Heartbeat Supercharger - 14 psi | E-50 (DSX Flex Fuel kit) | JMS FuelMax Fuel Pump Booster | LPE Big Bore High Volume DI fuel pump | LPE High Flow DI fuel injectors | LT5 95mm TB | RotoFab CAI | AEM X-Series OBD2 wide band gauge | Elite Engineering E2-X catch can | Borla S-type NPP Cat-Back 3" exhaust | Forgeline GTD1 5-lug Satin Graphite | SunTek wrap | C-Quartz Finest Reserve ceramic coated

|

|

|

|

|

|

#3 |

|

'It's an experiment'

Drives: [COTW 2/09/15] '11 GPI LSA SC Z/LE Join Date: May 2014

Location: Dallas TX

Posts: 8,694

|

Gates RPM belts are their racing belts. That is what I use, and I road race with them.. I’ve now gone full 3 belt LSA pulleys...

-Don

__________________

747 RWHP 794 RWTQ

"Horsepower sells cars, torque wins races." - Enzo Ferrari See My Build: http://www.camaro5.com/forums/showthread.php?t=385577 |

|

|

|

|

|

#4 |

Drives: 2011 2SS Join Date: Jan 2014

Location: PA

Posts: 83

|

Gates rpm belts are what I have been using. I'm found they are supposed to be high quality and I don't want to blame the belt. Is the stock lsa tensioner garbage, do I need a super tensioner?

|

|

|

|

|

|

#5 |

Drives: 2018 ZL1 1LE - HBM, PDR Join Date: Jun 2017

Location: Rescue, CA

Posts: 324

|

The belt I broke was a brand new Gates RPM belt too.

So with the RPM belt installed where does your tensioner sit in relation to fully compressed limit versus fully expanded limit (with no belt)? Sent from my SM-G950U using Tapatalk

__________________

JRE Tuned (HPTuners) | 15% OD (9.17" crank pulley) | TVS2300 Maggie Heartbeat Supercharger - 14 psi | E-50 (DSX Flex Fuel kit) | JMS FuelMax Fuel Pump Booster | LPE Big Bore High Volume DI fuel pump | LPE High Flow DI fuel injectors | LT5 95mm TB | RotoFab CAI | AEM X-Series OBD2 wide band gauge | Elite Engineering E2-X catch can | Borla S-type NPP Cat-Back 3" exhaust | Forgeline GTD1 5-lug Satin Graphite | SunTek wrap | C-Quartz Finest Reserve ceramic coated

|

|

|

|

|

|

#6 |

Drives: 2011 2SS Join Date: Jan 2014

Location: PA

Posts: 83

|

I never happened to check where it sat on the marks after install all I can say though is with the tensioner fully compressed while installing belt and then after releasing it, the tensioner litterally only moved 1/4"-1/2". This did not seem like enough. I also checked all the pulley alignments and they are spot on. But this time with this break the stock plastic pulley broke and cut the lower rad line. It seems there's a lot of guys still running the stock tensioner

|

|

|

|

|

|

#7 |

|

'It's an experiment'

Drives: [COTW 2/09/15] '11 GPI LSA SC Z/LE Join Date: May 2014

Location: Dallas TX

Posts: 8,694

|

Can you show a pic of the belt routing and pulley setup? Breaking a new RPM belt is something so would want to ensure routing and belt alignment.

This is where you want the belt tension (between these marks):  ADM LSA belt routing:  -Don

__________________

747 RWHP 794 RWTQ

"Horsepower sells cars, torque wins races." - Enzo Ferrari See My Build: http://www.camaro5.com/forums/showthread.php?t=385577 |

|

|

|

|

|

#8 |

Drives: 2011 2SS Join Date: Jan 2014

Location: PA

Posts: 83

|

I will post a pic of spare belt and tensioner marks when I get home. Is there also any way to test if the tensioner is bad?

|

|

|

|

|

|

#9 | |

|

'It's an experiment'

Drives: [COTW 2/09/15] '11 GPI LSA SC Z/LE Join Date: May 2014

Location: Dallas TX

Posts: 8,694

|

Quote:

-Don

__________________

747 RWHP 794 RWTQ

"Horsepower sells cars, torque wins races." - Enzo Ferrari See My Build: http://www.camaro5.com/forums/showthread.php?t=385577 |

|

|

|

|

|

|

#10 |

Drives: 2011 2SS Join Date: Jan 2014

Location: PA

Posts: 83

|

Ok so I just installed a new k061005 and it's dead nuts between the 2 marks. When I had the k061000 installed it wasn't even barely at the bottom alignment mark when I released the tensioner onto belt. So it seems the k061005 is the correct size?

|

|

|

|

|

|

#11 |

Drives: 2011 2SS Join Date: Jan 2014

Location: PA

Posts: 83

|

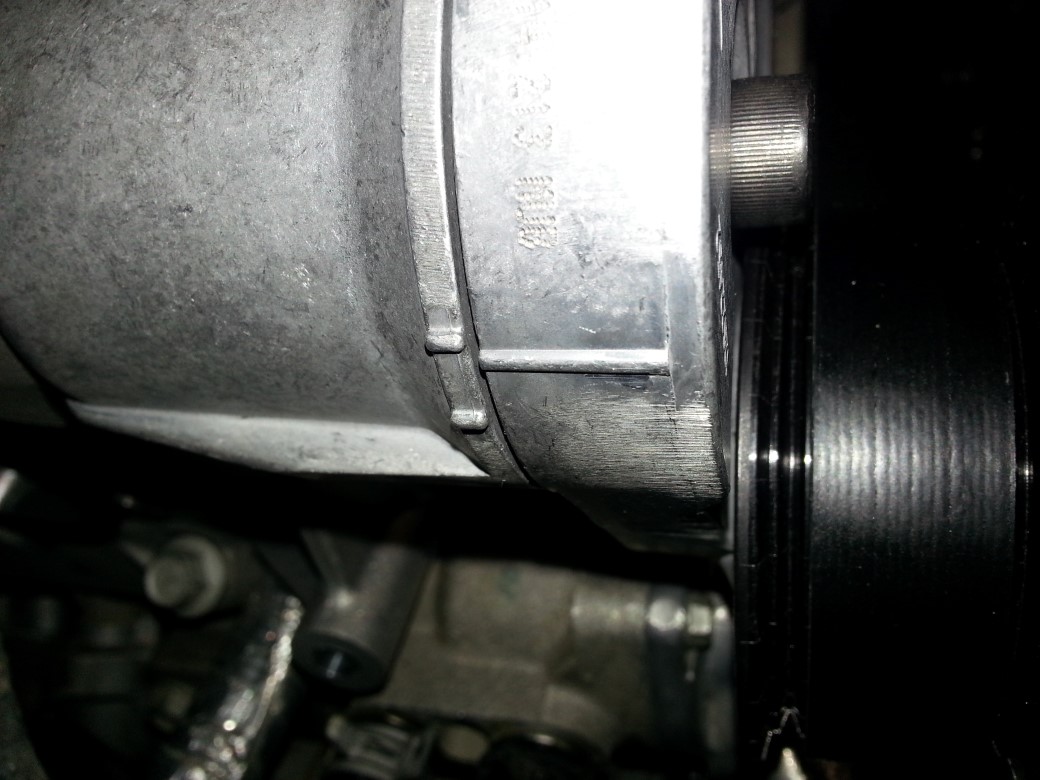

And you can see in this photo how it broke the back of the plastic tensioner pulley off.

|

|

|

|

|

|

#12 |

|

'It's an experiment'

Drives: [COTW 2/09/15] '11 GPI LSA SC Z/LE Join Date: May 2014

Location: Dallas TX

Posts: 8,694

|

You'll need a new pulley for sure on the tensioner -- as I'm sure you're aware ;o). Right in the middle is fine.. That is where mine is too -- I do have and RPM belt on mine also...

-Don

__________________

747 RWHP 794 RWTQ

"Horsepower sells cars, torque wins races." - Enzo Ferrari See My Build: http://www.camaro5.com/forums/showthread.php?t=385577 |

|

|

|

|

|

#13 |

Drives: 2018 ZL1 1LE - HBM, PDR Join Date: Jun 2017

Location: Rescue, CA

Posts: 324

|

Food for thought and just another perspective. I am not so sure the RPM series belts are better than the Green Stripe belts. I originally had to have the RPM belt. All my reading suggested that this was the belt to have to prevent belt slip. Perfect for blower applications. These belts are apparently made of an Aramid/Kevlar like composite that makes them extremely stretch resistant and supposedly very strong.

When I installed the exact same size RPM belt as the Green stripe belt, I immediately noticed that the tensioner virtually did not move after I slipped the belt on and released compression unlike the Green stripe belt which you could see stretch a bit. In my case I am certain that the real cause of the RPM belt break was a maxed out tensioner. However, it really got me thinking that maybe a little belt stretch and possibly a bit of slippage might be a better alternative than a broken belt. My theory is that the RPM belts have zero give thus forcing the belt to break under strain. If you've broken 3 RPM belts, I would ditch the RPM and run a Green Stripe. I no longer run RPM belts. Green Stripe only for me. 2 cents.

__________________

JRE Tuned (HPTuners) | 15% OD (9.17" crank pulley) | TVS2300 Maggie Heartbeat Supercharger - 14 psi | E-50 (DSX Flex Fuel kit) | JMS FuelMax Fuel Pump Booster | LPE Big Bore High Volume DI fuel pump | LPE High Flow DI fuel injectors | LT5 95mm TB | RotoFab CAI | AEM X-Series OBD2 wide band gauge | Elite Engineering E2-X catch can | Borla S-type NPP Cat-Back 3" exhaust | Forgeline GTD1 5-lug Satin Graphite | SunTek wrap | C-Quartz Finest Reserve ceramic coated

|

|

|

|

|

|

#14 |

Drives: 2011 2SS Join Date: Jan 2014

Location: PA

Posts: 83

|

I have since contacted gates and spoke with them regarding their rpm belt and was told yes they are designed for supercharged applications and designed to NOT stretch or give. TMS I agree with you I would rather the belt slip than break. It costs me a pulley, belt, rad hose, coolant and track time. I have a continental elite in garage ready to go on but I think I'm going to get the green belt and keep the elite for spare. I did order a billet tensioner pulley but BTW has anyone found the need to swap the black metal idler pulley (the one below and to the left of the supercharger pulley) to a billet one?

|

|

|

|

|

|

|

|

|

|

|