You are browsing camaro5

|

|

|

#1 |

|

Drives: G5.R Join Date: Sep 2010

Location: SoCal

Posts: 2,377

|

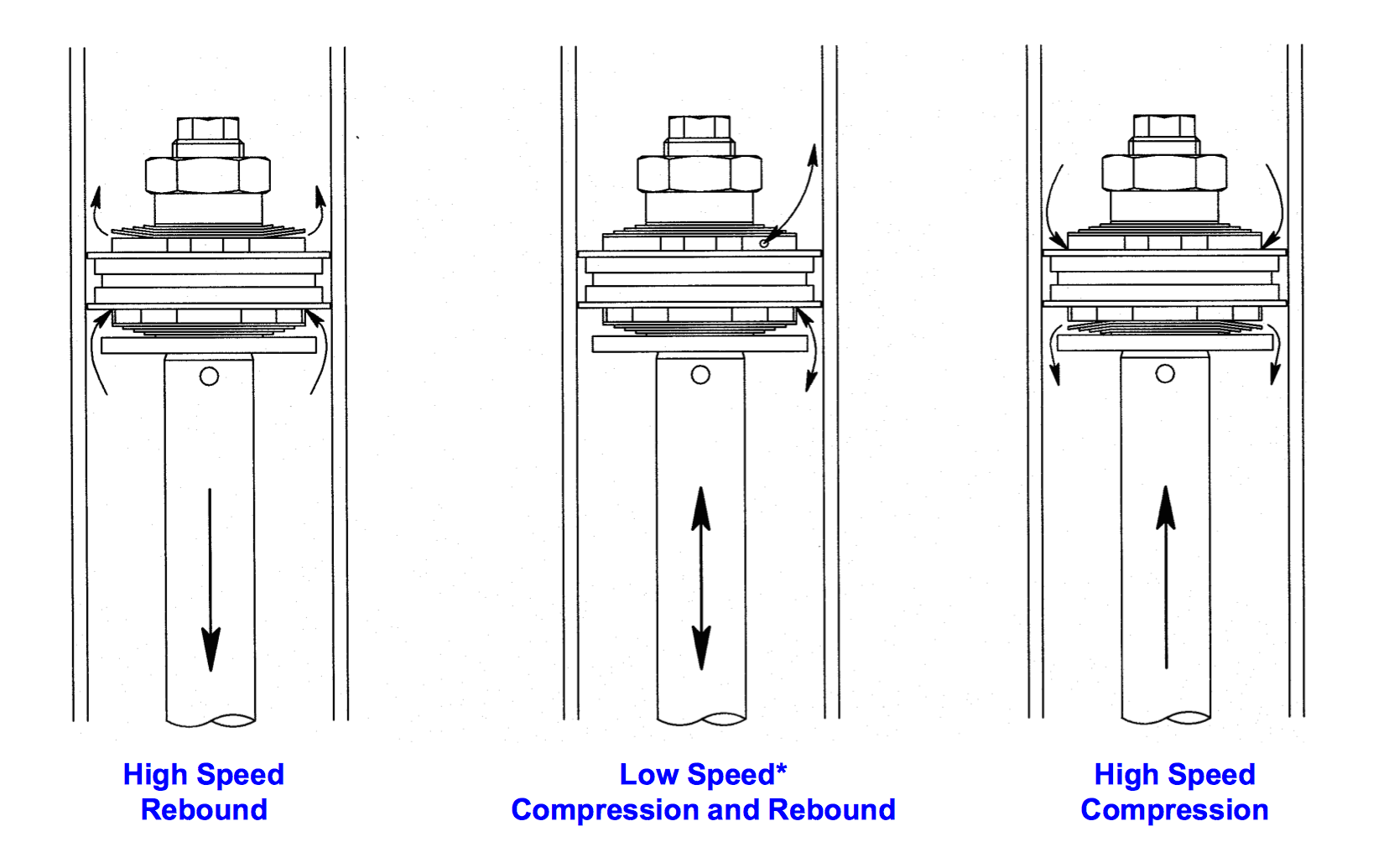

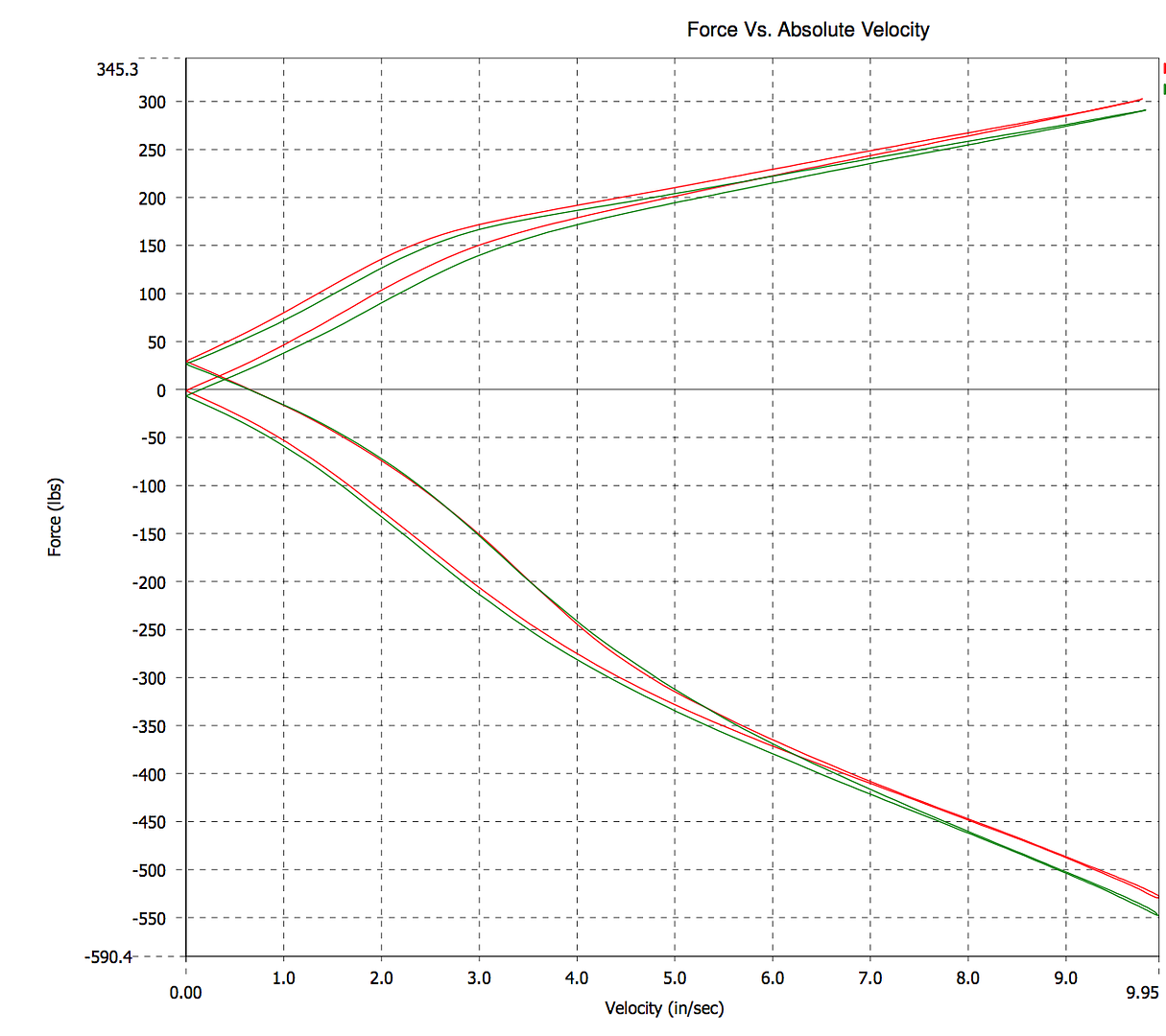

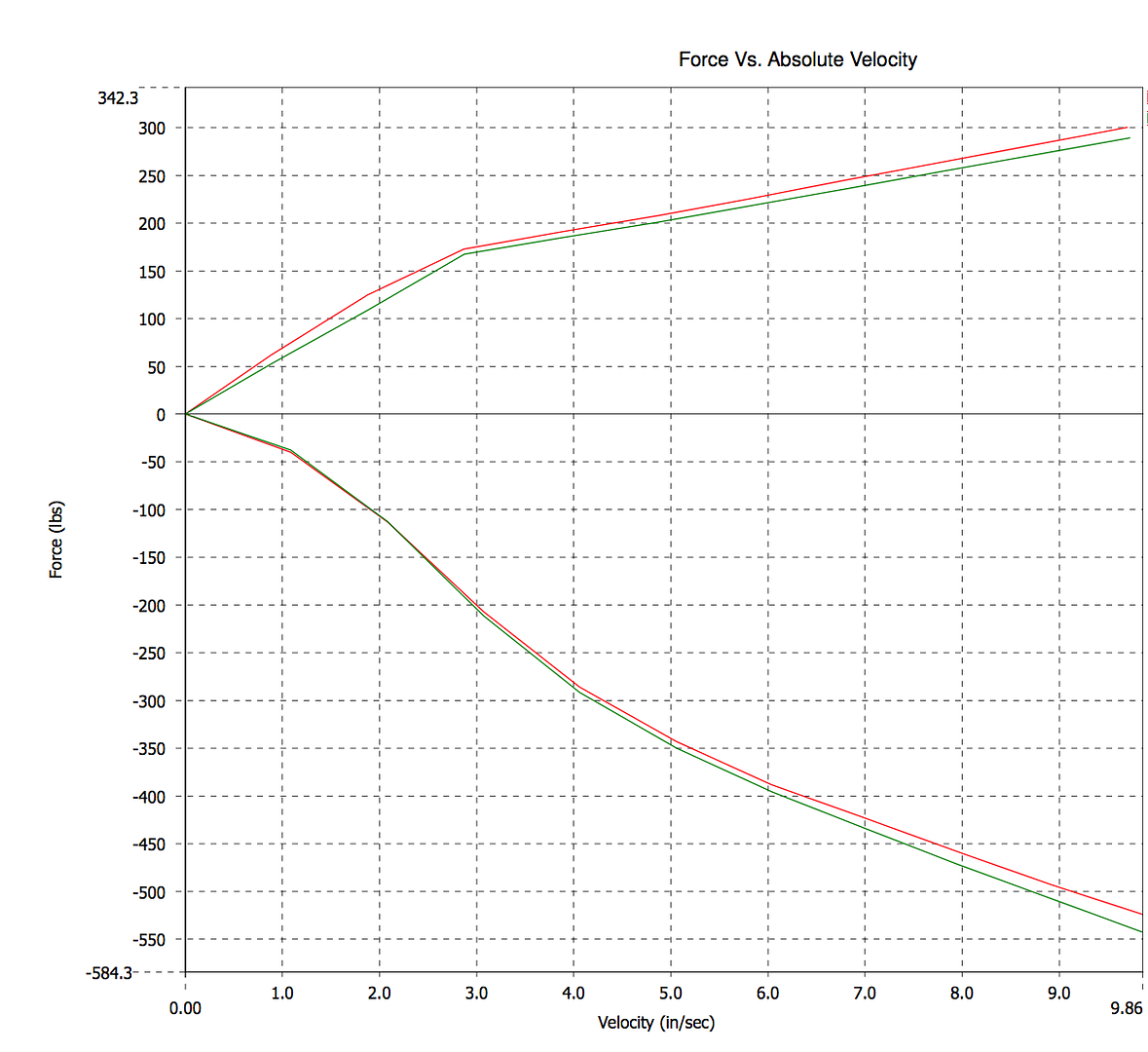

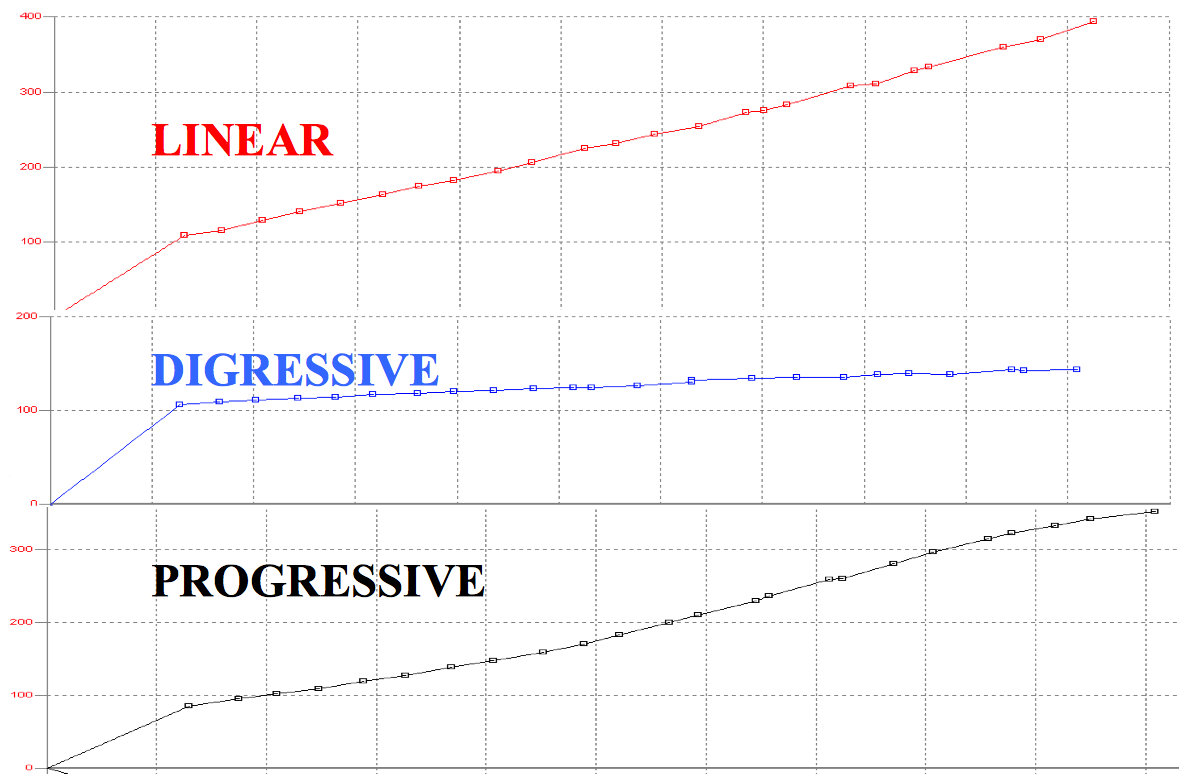

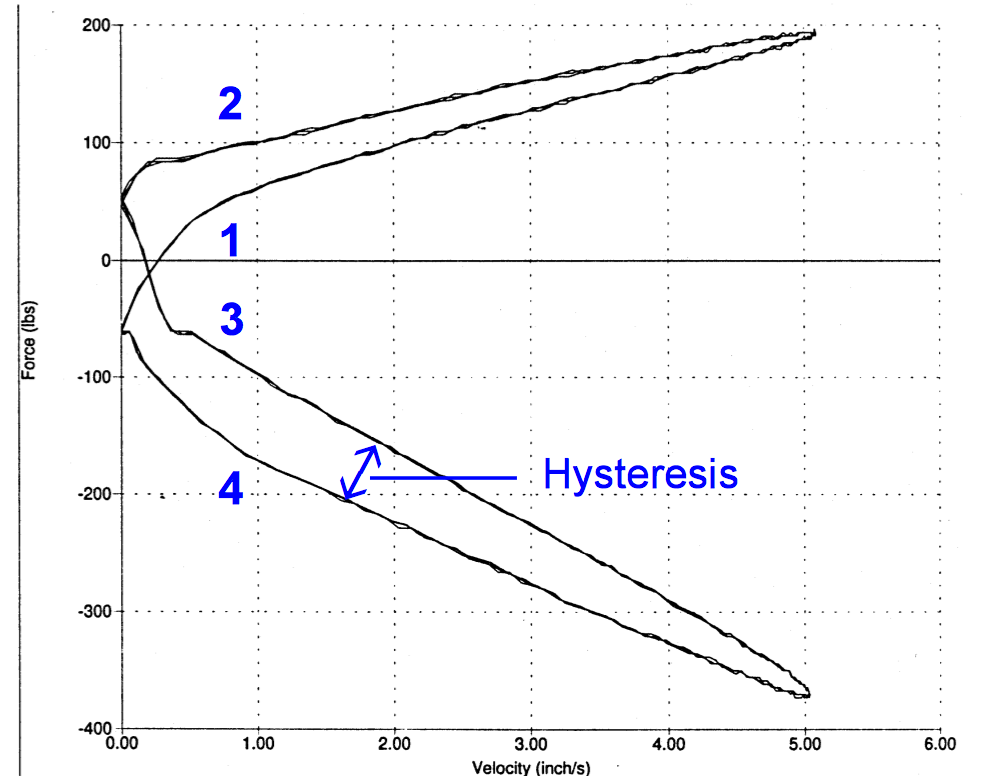

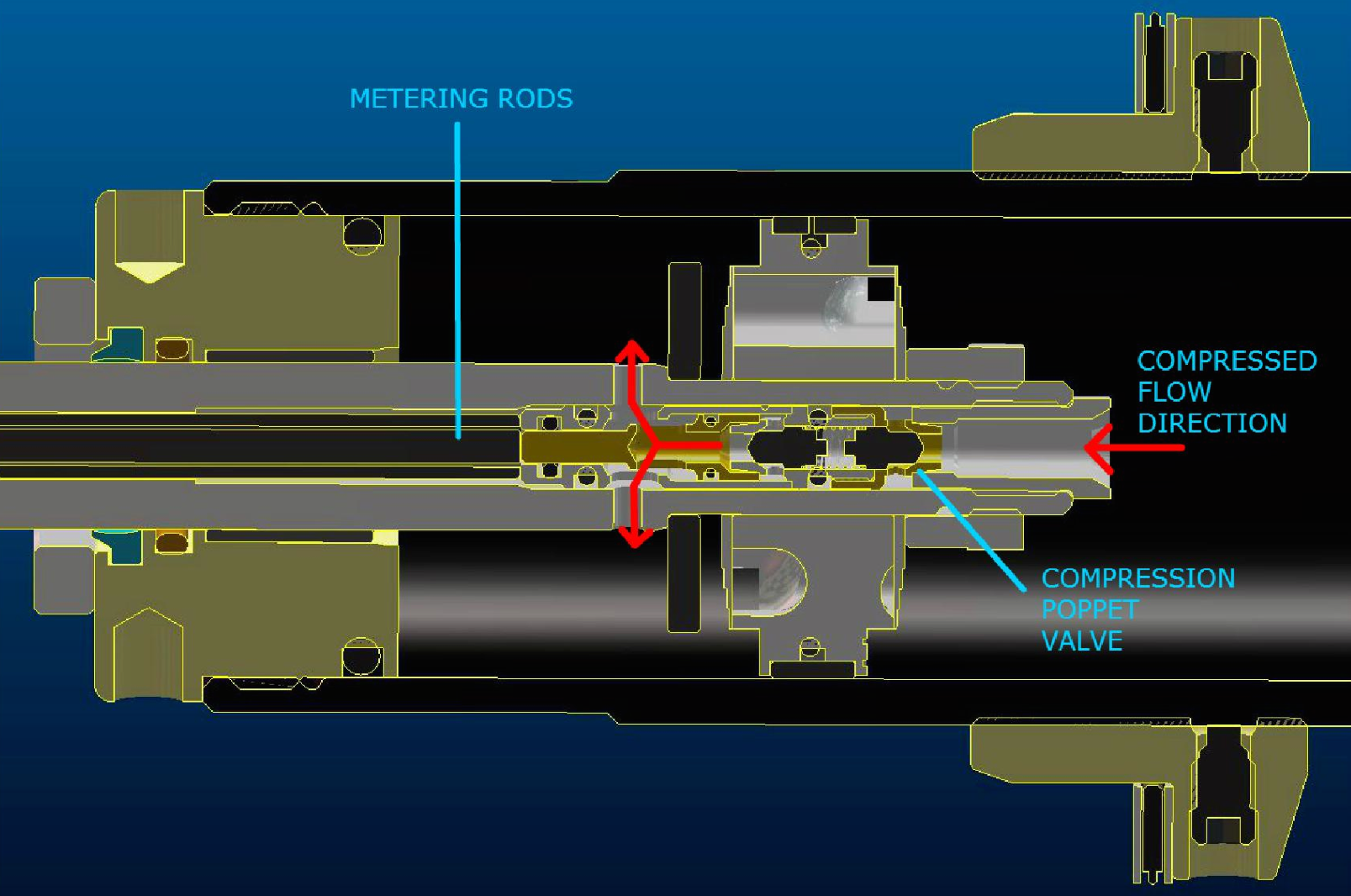

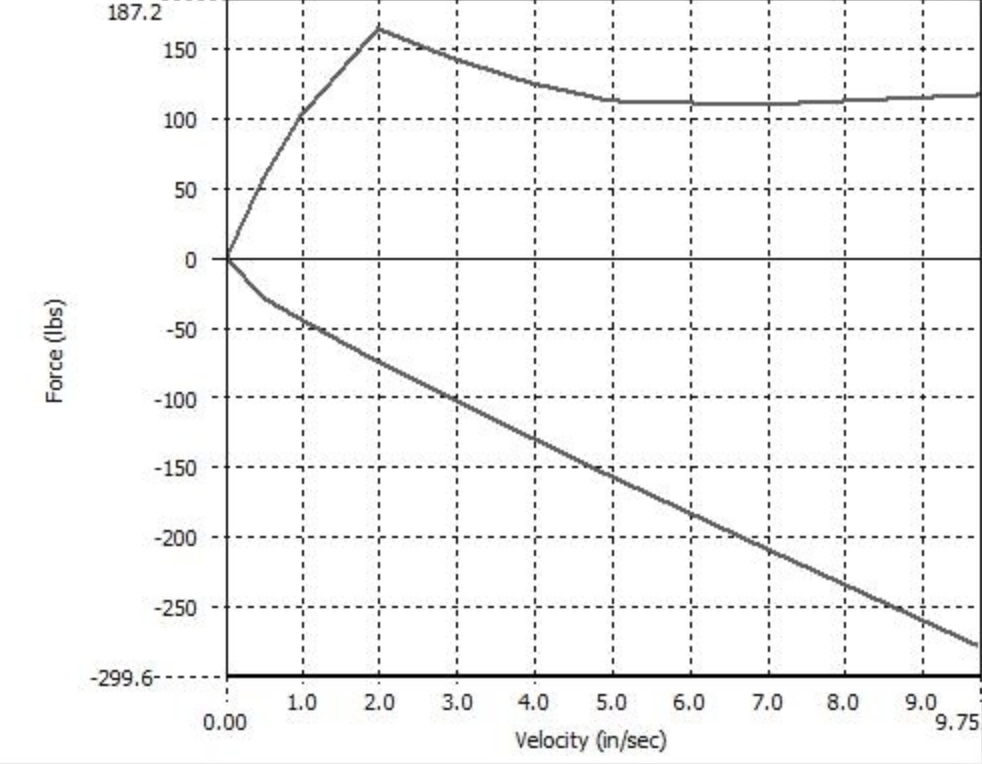

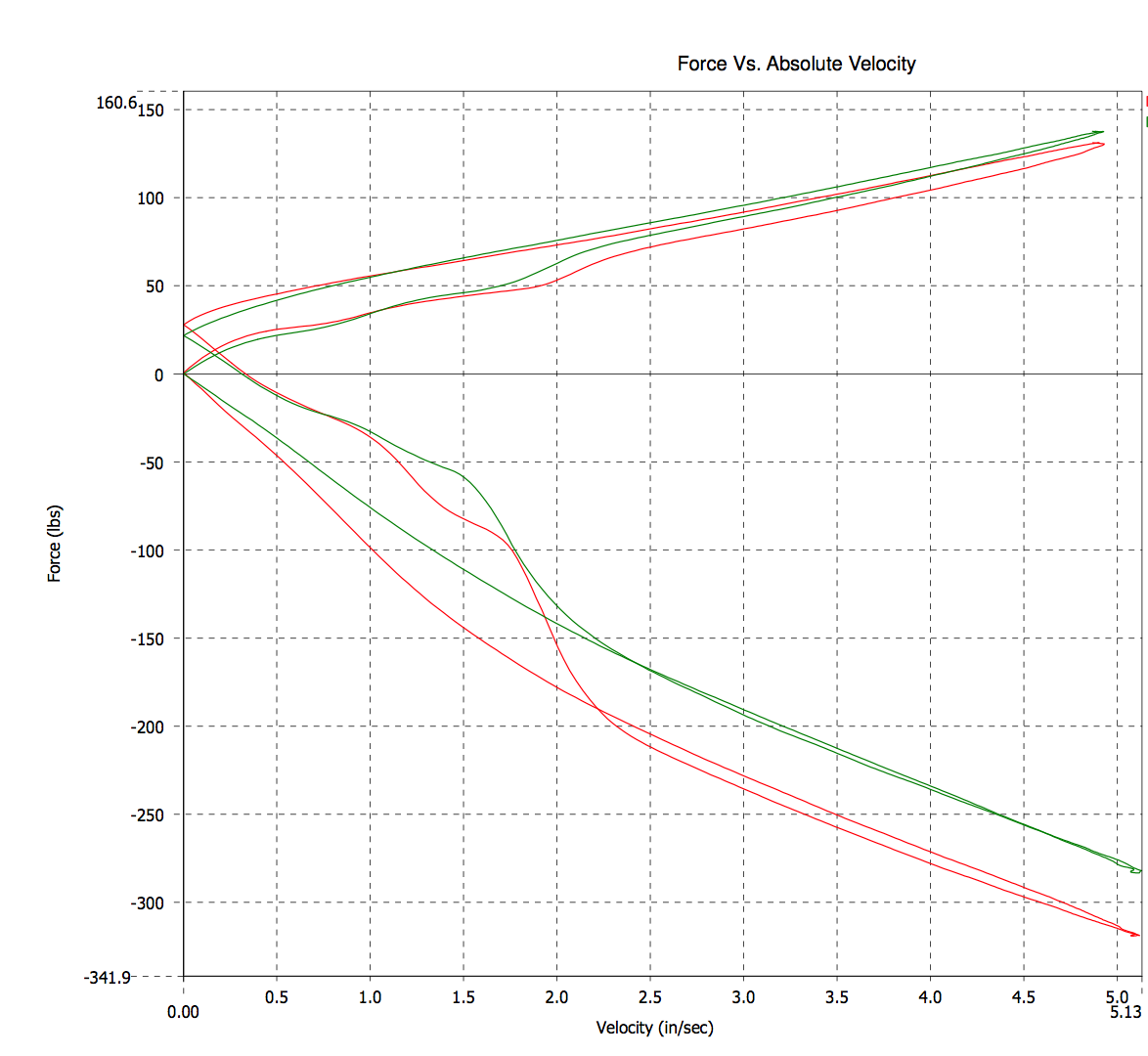

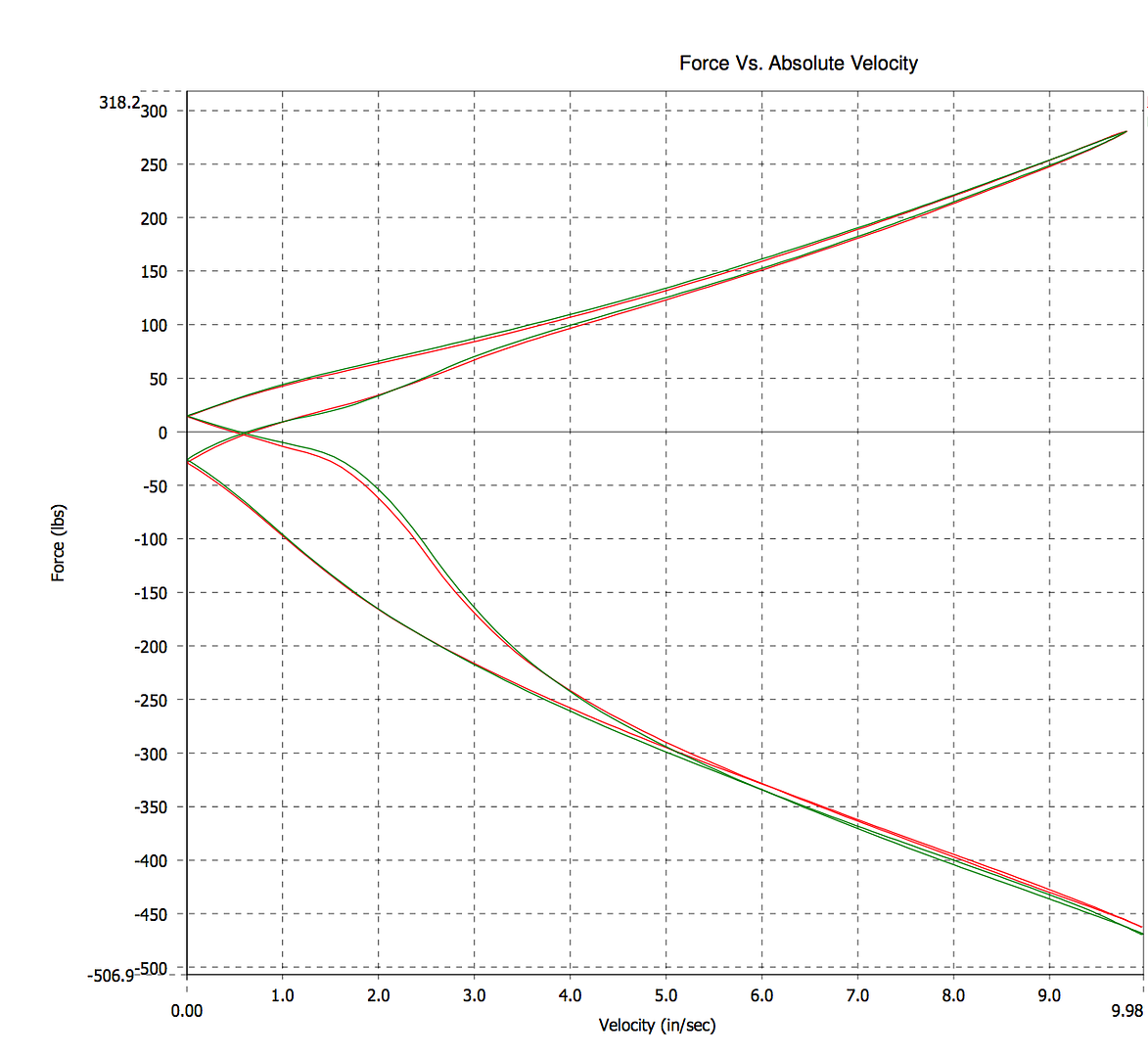

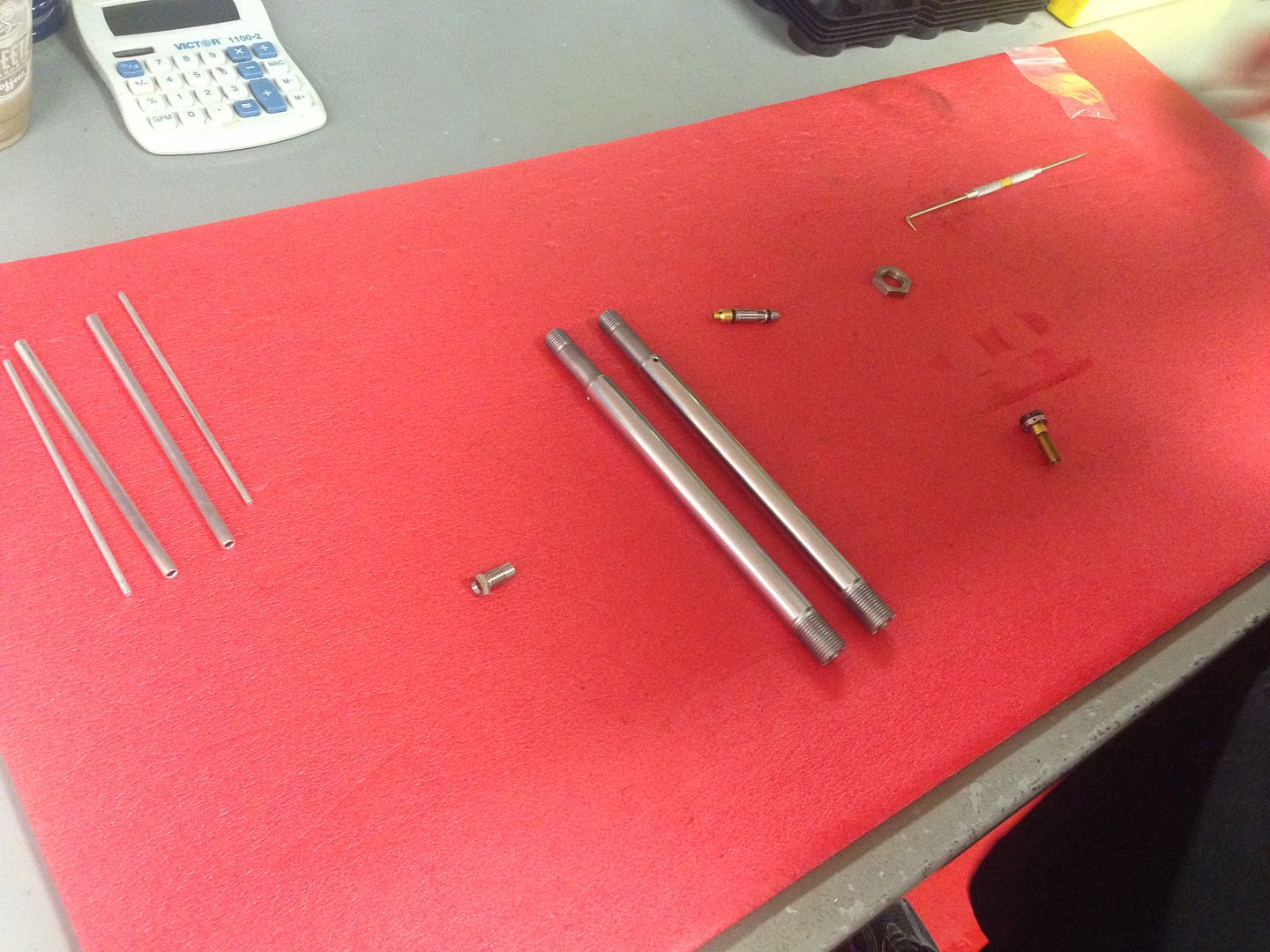

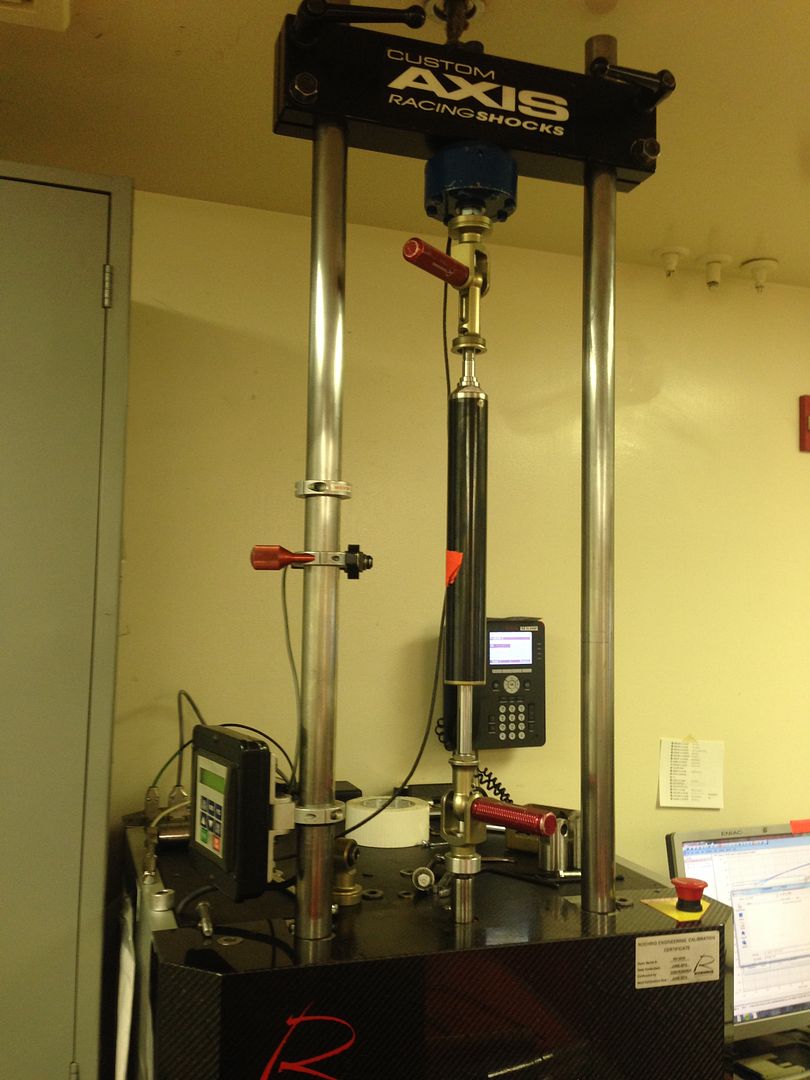

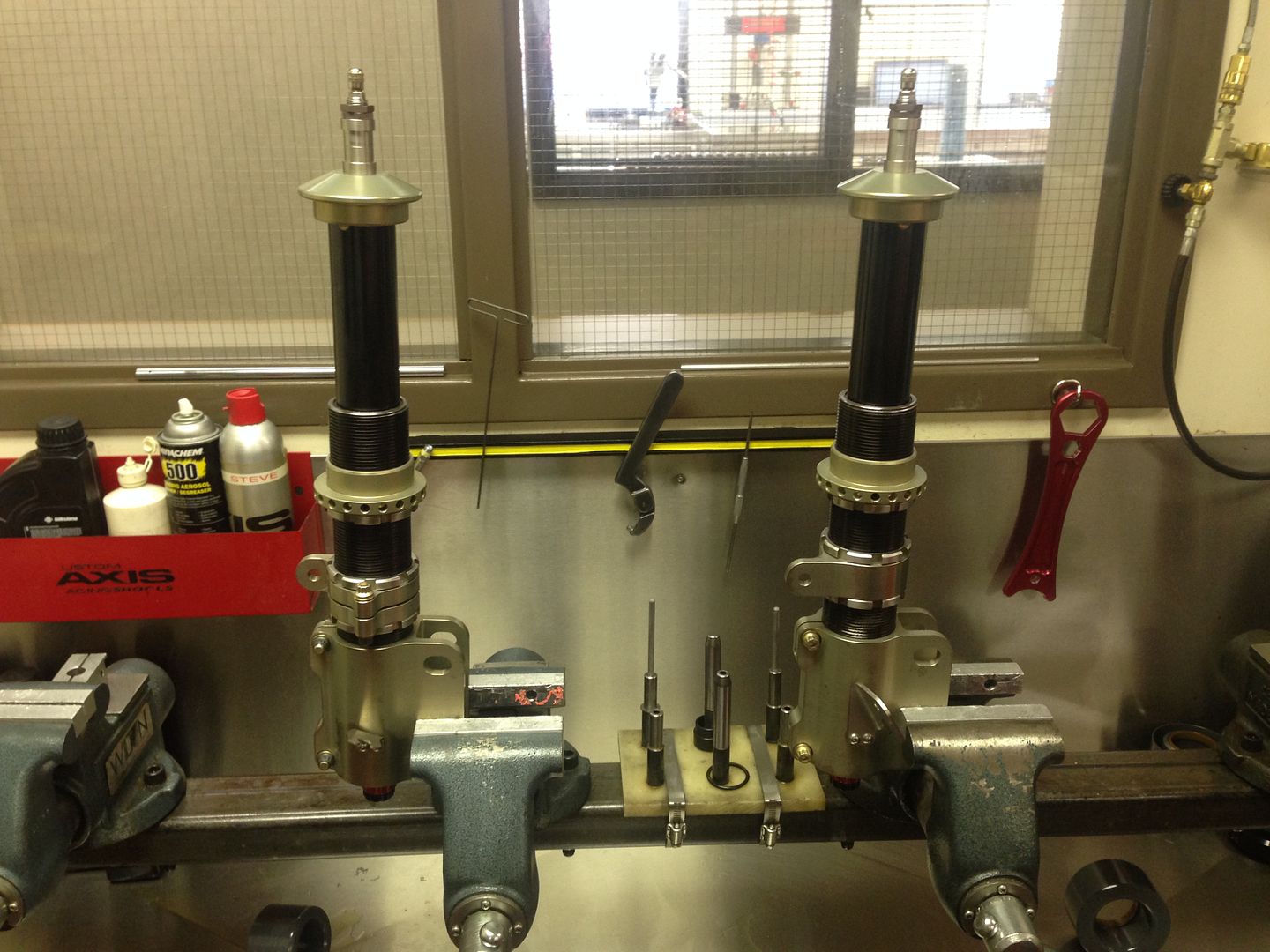

Dampers 101, and why we chose Penske Racing Shocks

Hey Guys, Some of you may know that we decided to go to a different shock/strut set up than the pfadts. We decided to upgrade to what is IMO the best aftermarket damper available for any car any where, I.E. Penske Racing Shocks. In this thread, I hope to cover our motivation for choosing Penskes over other options available to the camaro market. I will attempt to thoroughly go over the "Penske advantage”, so you guys can understand exactly what warrants the higher price tag on these high end dampers. Before going on, I’ll let you know that I'm going to be touching on some technical stuff, which may require some basic damper knowledge (particularly monotube dampers), so here are some quick bullet points to freshen up your memory, if you’ve learned this before. If you are new to dampers, you might need some further reading to fully understand what i’ll be talking about below. - If you look at either side of the piston, you’ll see a pattern of orifices. some that are closer to the OD of the piston and others that are closer to the ID. The outer orifices on the compression face are the path of the inner orifices on the rebound face, and vice versa. When the piston moves through the shock oil, the oil will flow in through the outer orifices, and out through the inner orifices on the other side. - Shim stacks on each face determine the valving of the shock. On the piston rod side is your compression stack, and the rod nut side is obviously your rebound stack. the shim stacks cover the inner orifices on each side, so when oil flows through, pressure will cause the shims on the corresponding side to flex and allow the oil to flow. Generally, the stiffer (thicker) the shims, the more force it will take for them to flex, I.E. the more damped the shock will be. Pistons will often have a 1-3 degree dish in them to preload the shims; more preload on the shims result in more damping, and will cause a “snappier” blow off.  - Some, not all, mono tubes will have a bleed hole from one side of the piston to the other. This bleed hole allows for shock oil to bypass the shim stacks all together at low shaft speeds. Shocks with low speed rebound adjustability will commonly have a bleed hole in the shaft  - When the shock compresses, the shaft is entering the shock body, and takes up space. Liquid is incompressible, Gas is compressible, which is why shocks need some degree of a gas charge inside the shock body, to compress and allow the oil displaced by the piston rod to go somewhere. - In most mono tube dampers, there’ll be a floating piston, either in the shock body, or in the remote canister if the damper has one, to separate the oil from the compressible gas (nitrogen). This pressurized gas is also what allows a monotube shock to be oriented any way in a car and still function at 100%. - Too little pressure in the nitrogen chamber can be a source of cavitation in the shock body. This is because little pressure behind the floating piston means little resistance, even less so than the resistance from the compression shim stack. What that means, is that at higher speeds, the floating piston will actually move up before the compression stack flexes and allows oil through to the other side. And since liquids can’t compress, it also can’t expand, so on the opposite side of the main piston (the shaft side), there becomes unoccupied space very quickly, and the oil is literally torn apart. This is called cavitation. At penske, they have this really cool see through shock body, that illustrates cavitation 100 times better than I could ever explain it, so I took a video of it to show you guys. Unfortunately... My phone recently broke and I lost the video in it. So here is a video of a clear shock I found on youtube, which just as well illustrates cavitation. - In this thread, you’ll see some shock dyno plots which I will use as examples for the topic at hand. - A CVP plot will be based on the top speed you set the dyno to run for that test. The dyno will take several measurements of the force at each shaft velocity as it accelerates in compression, decelerates in compression, accelerates in rebound and decelerates in rebound. So on a CVP plot, you will see one continuous loop, with 4 section, where each direction change is a change in acceleration of the shaft. Compression is usually reflected on the top half (positive) portion of the graph, and rebound is reflected on the bottom (negative) portion.  - When a PVP plot is run, several different peak shaft speeds are input into the dyno software, and the dyno will run the shock at each velocity input, record the force at that velocity, and move on to the next velocity input. The data is then averaged and plotted onto the graph. Since the plot is only based on peak velocities, there will be 2 lines, one for compression and another for rebound. PVP plots are what you’ll see on the internet most commonly, simply because they are easier to read. Again, compression is on top, rebound on bottom.  - There is also a force vs position graph, AKA the football graph, which I won’t be covering. - There are 3 different basic types of force curves, linear, digressive, and progressive. - In a linear curve, force will increase linearly (go figure) as velocity increases. - In a digressive curve, force will increase at a rate that is decreasing as velocity increases. - In a progressive curve, force will increase at a rate that is increasing as velocity increases. - These are how the curves are defined, however, on a dyno plot they all may look fairly linear with a change in direction at some velocity, which will determine whether it is progressive, digressive or linear. See examples below.  - As the piston accelerates, it will have a curve that will be similar, but not identical to the curve as the piston decelerates in its stroke. The difference between the accelerating profile and the decelerating profile is called hysteresis. This means force at 5 in/s (arbitrary) while the dampers is accelerating in bump will be different (lower) than the force at 5 in/s when the shock is decelerating in bump. Hysteresis can be most easily be seen in CVP plots. A quality damper will generally have minimal hysteresis. In the graph below, 1 is compression accelerating, 2 is compression decelerating, 3 is rebound accelerating, and 4 is rebound decelerating.  Really, the info above is barely even scratching the surface. But something I want to emphasize is that there is no “best” shock. There is good shocks, yes, but to get into “best” you have to start looking at the specific (and by specific, I mean vehicle weight, tire compound, spring rate, ARB rate, aerodynamics, etc.) car, and the driver of the car. __________________________________________________ __________________________________________________ __ OK, so why did we go with Penskes? Well, here are a few reasons... Domination of the top tier race car market Simply put, Penske racing shocks are recognized in the racing industry as THE damper to have in your car. Next time you are at the races, check the suspension in the winning car. Chances are, you’re gonna see some Penske gold.. In F1, 75% of race cars are running on Penske. In Indy car racing, 80% of race cars are running on Penske. In NASCAR, 100% of race cars are running on Penske. In Tudor-DP (prototypes), 90% of race cars are running on Penske. In NHRA Pro Stock, 100% of race cars are running on Penske. What is holding up the Z/28.R race cars in the IMSA CTSCC series? Penske Racing Shocks   I would say they are doing something right. Take note that this is not because Penske is sponsoring all the winning race teams by giving them free product. Racing is Penske’s market… Every one of those teams has to pay up for their dampers. If Penske gave out parts, there wouldn’t be very much money to make since the street market rarely can afford, or justify the cost of a top tier damper set. Additionally, in racing, if the team sees a part or opportunity that will help them go faster, they will take it. Period. This fact of racing keeps Penske on their toes, constantly bettering their offerings. Superior technology adapted from F1 As mentioned above, there is a good portion of F1 cars that run on Penske shocks. F1 is internationally regarded as the highest form of automotive racing, and as such, is always evolving with different trick ways to get the car faster than the other guy. While I was at Penske, I saw that the design engineers were hard at work thinking of different ways to improve an F1 damper. Each and every year, and even mid year, the engineers must come up with something new, that promises to be better than last years, or else they will fall behind. These shock engineers will never reach a “best” design, simply because they are always looking to come up with a design that is better than the last, and will never stop. So what does that mean for us? Well, Penske users get to take advantage of this never ending pursuit of the perfect damper through trickle down effect. One particularly trick tech that is built into our dampers is called “dual bleed adjusters” (DB). Penske DB dampers allow oil to flow through small ports on the shaft right before the piston and through the bottom of the shaft, bypassing the shim stacks during low speed inputs. Low Speed, which is typically the 0 - 3 in/s portion on a shock dyno plot, is going to be what the driver feels the most, from cornering, braking, and accelerating. And unlike other dampers, Penskes with DB tech allow the user to individually adjust LS compression and LS rebound, making them the most effective dampers for on track tune-ability. I.E. If you are running on the track, and your car feels like it is rolling around a lot, high speed adjusters, in compression or rebound, aren’t going to do much for you. In such a case, you would need more low speed damping to control the car. As another example, going from a summer tire to an R-compound (increasing grip) will typically require more LS damping as well… and vice versa. Below is a Diagram I grabbed from Penske which shows nicely what is going on inside a DB damper.  More info on Dual Bleed tech, click here Another very cool innovation, also originating in F1, though I’m not sure if it has been tested on street cars yet, is Penske regressive technology. I’m not going to even attempt to explain how it all works, but basically Penske has come up with a way to achieve a regressive force curve, meaning at a set shaft speed, the piston will "blow off” and force will actually decrease as shaft velocity increases. such technology allows racers to be nearly unaffected by bumps on the race track, or candy cane curbs, and even use them to their advantage.  More info on regressive curve technology, click here Other neat innovations, like velocity dependent piston (VDP), and variable bleed (VB) pistons, allow users to tune their shocks to get the exact curve they want. And with a very modular design in all of their dampers, almost everything is interchangeable, which means users can take advantage of new tech that may come out in the future, by swapping out some of the internal components, which brings me to my next point. Strong emphasis on user rebuild-ability Penske shocks are put together with basic tools. Nothing special is needed for assembly… in fact the most complex tool used is probably the spanner wrench. This makes it very easy, comparatively speaking, to assemble and disassemble the dampers. So when it comes time to change out some seals, put in some fresh shock oil, or even a revalve because you are at full stiff and need more damping, you can do it yourself without much struggle. To open up one of the rear shocks is about 5 steps.. - Remove spring and hardware from shock - Set rebound to its softest setting - Clamp shock in vice with shaft on top side - Depressurize the shock via the schrader valve - Unscrew shaft bearing with spanner wrench That is literally all it takes to open up the shock… Penske has the whole step-by-step process written in detail for disassembly and reassembly in their shock tech manuals (click here , page 13). The struts are a bit more involved, but definitely much more simple than any other strut I have seen. Custom built for the users specific needs They don’t really do “off the shelf”. The only things they grab from the shelf are the parts they are using to assemble your custom dampers. Penske will take info from you, like your vehicle weight, your intended use of the car, and custom modifications into consideration when building your dampers. If you have any custom requests, they will take care of you. Have a specific force curve that you want? Not a problem. Everything Penske builds is custom, and they will listen to you and what you want, then use their extensive experience in racing to give you a damper that is perfect for your application. Customer service/feedback Everyone that works at Penske is a car guy. Flying to PA and being able to check out their facilities, I also got to meet some of them and talk. Even with some of my dumb questions, they were very cool and willing to help me learn. If you ever had any questions on your Penske shocks/struts, their extremely knowledgeable technicians are a phone call away from helping you solve whatever problem or answer whatever question you may have. If you wanted to disassemble your strut, they can spend some time on the phone with you and give you some helpful tips on the process. Penske Tech’s can even give you feedback with shim stacks should you decide on a revalve, and get you pointed in the right direction. Penske tech’s are there for whatever shock/strut/spring concern you may need assistance with. Unmatched Quality Control OK, this one is a big, and important, and very often IGNORED factor. When you get buy dampers from penske, you are always provided with a dyno chart from your specific damper configuration. Penkse provides these charts for a couple reason: To show the buyer their force curve as the shocks are shipped, and to show the consistency between the left and right dampers. At first, while I thought it was a cool perk to buying penske, I wasn’t sold on it being completely necessary. However, I had a complete change of mind after assembling the shocks with the tech over there. When we were assembling the rear shocks for our project G5.R, we used identical components for each side (duh), and threw the shocks on the dyno to see the result of our valving. Well, here is a CVP dyno plot comparing the RR and RL shocks the first go around.  Alright, somethings up... At 1.5 in/s, the RR had an increase in rebound, and was about 40lbs more damped from from 2 in/s on. Unacceptable! So we started shooting ideas out as to what may have been the cause for the mismatched curve. Forgot to torque the shaft nut? nope… wrong sized shim in the stack? nope…. we spent an hour going back and forth with the shock, testing our theories on the cause by running the shock on the dyno again. Curves were still not lining up like we wanted. Opened up both rears once more and took a good look at the pistons in comparison. They were physically IDENTICAL, not a single difference that any human eye can detect, except for the fact that the anodizing from one to the other was just slightly different hues, indicating that the pistons were machined from separate batches. Somewhat skeptical of a finding a solution, we decided to try another piston that matched colors better. Sure enough, as soon as the new dyno charts showed up, we realized that was in fact the problem, and the rears matched perfectly now.  Moral of the story is that it is VERY IMPORTANT that the dampers you buy have been dyno’d before they were sent to you, and you are given a copy of the plot!!! If a shock company is refusing to provide you with this data, be suspicious! It is your money, you have the right to be. To add to that, here is a picture of an in progress build of 200 NASCAR shocks, which all need to be within 2% of each other on the dyno plot. Each and every one of these shocks has been on the dyno, and several more than once, to get them within spec.  Ability to go to their facilities and build YOUR dampers with a Penske technician Well, I’ve alluded to this throughout the thread, but basically, any customer of penske is allowed to spend a day with them putting your very own package together. I took advantage of this, despite being on the complete opposite side of the country, and I feel it was well worth it. I learned a ton of cool things while I was there, and got some hands on experience dealing with shock guts. I also realized that they really do build our lowly camaro dampers along with Indycar, NASCAR, IMSA, Le Mans, and whatever other racing series you can think of, out of the same parts bins. Here is a series of pictures that I took while I was at Penske, showing you the build process, and some of the various components, to tie into my "shock lecture" earlier. Piston Rods  The heart of the dual bleed shock. as simple as this tiny part may seem, it was actually extremely complex, and the machining detail required was astonishing.  Rear shock shaft bearing  Rear rebound and compression adjusters  Ready to install the spec'd shim stack along with the piston.  This is the piston for the rears. It is a VDP (Velocity Dependant Piston) which I mentioned earlier in the thread. Notice the piston band is slightly smaller than the groove for it. This is a trick that Penske employs to maximize tire grip over small road undulations. Not something you'll see in a run of the mill shock absorber.   Piston assembly installed  Bleeding the rear shocks. the grey cup around the shock body is used to catch any spilled shock oil without making a mess.  Tightening the shaft bearing  Rear Shock on the dyno  Rears all put together and ready to go  Here's a bunch of assembly components for the struts.   Lower strut assembly  Strut on the dyno  struts fully assembled  OK, cool. So what Well, after reading all of that, I wouldn't be surprised if you were assuming that penskes must be very expensive.... and you would be right. As I am sure you could derive, producing a top tier racing shock comes at a price. HERE IS THE GOOD NEWS: Moreno Motorsports has partnered up with Penske to offer a special promotion to our customers! This offer is EXTREMELY LIMITED, RESERVED FOR THE FIRST 5 BUYERS, and TOO GOOD TO POST ON THE FORUMS. I GUARANTEE that you will never find Penske's at this price anywhere else. There are several different Penske coil over packages with different ranges of adjustability available. 7500 Single adjustable (Rebound bleed) 7565 2 way adjustable (Rebound bleed, compression bleed) *** 8300 2 way adjustable with remote canister (rebound bleed, high speed compression) 8365 3 way adjustable with remote canister (Rebound bleed, compression bleed, high speed compression) 8765 4 way adjustable with remote canister (Rebound bleed, compression bleed, high speed compression, high speed rebound) *** IMO, the best "bang for your buck" is the 7565. This is because dual bleed adjusters will most effectively allow you to tune the driver feel of your suspension. Included in Penske/Moreno Motorsports Suspension package: - Penske Strut/shock package spec'd for your car - Coilover Spring package spec'd for your car - (optional and highly recommended) Moreno Motorsports Camber/Caster plates - (optional and highly recommended) Moreno Motorsports solid mount rear shock hat Before buying what you though was the best suspension package for the fifth gen camaro, I urge you to contact me about this package! The worst case is you decide against it, and the best case is you end up with the absolute best dampers ever available to the fifth gen camaro. Do it. Thanks, Justin Moreno Last edited by Moreno1; 01-22-2015 at 10:37 PM. |

|

|

|

|

#2 |

Drives: cars Join Date: May 2011

Location: Oversneeze

Posts: 4,544

|

Great post, any info/pics on the rear shock hat?

|

|

|

|

|

#3 |

|

Drives: G5.R Join Date: Sep 2010

Location: SoCal

Posts: 2,377

|

Thanks guys. I am hoping this thread can help some people whether or not they go with penske

Synner, I'll shoot you a PM with some info on the hats. |

|

|

|

|

#4 |

Drives: 2010 Camaro 2LT V6 Join Date: Jul 2009

Location: California

Posts: 439

|

I am interested in Penske. Can you email me the special? Thanks

__________________

Injen CAI, V-Max Throttle Body, Rx 25mm Iceolator, Rx 10mm Plenum Spacer, Mace Ported Manifold, ARK N-II Catback, Trifecta Tune, Rx Catch Can.

BMR Bushing Inserts,Pedders Radius Rod Inserts, Pfadt Sway Bars and Endlinks, LSR Front Subframe Brace SS Brembo Brakes, Racing Brake Stainless Lines |

|

|

|

|

#5 |

|

Drives: G5.R Join Date: Sep 2010

Location: SoCal

Posts: 2,377

|

PM coming your way

Updated the OP with some stats. In F1, 75% of race cars are running on Penske. In Indy car racing, 80% of race cars are running on Penske. In NASCAR, 100% of race cars are running on Penske. In Tudor-DP (prototypes), 90% of race cars are running on Penske. In NHRA Pro Stock, 100% of race cars are running on Penske. I would say they are doing something right. |

|

|

|

|

#6 |

Drives: 2010 2SS CGM Camaro, 1988 6.6L IROC Join Date: Mar 2010

Location: Bay Area

Posts: 157

|

Another consideration, Penske Shocks will not be going anywhere like Pfadt or Pedders USA did AND there are plenty of Penske Shock authorized suspension shops that can service, repair and revalve.

The only thing that would hold most people back are the higher price point of the Penskes. |

|

|

|

|

#7 |

Drives: 2013 ZL1 416 Join Date: Feb 2013

Location: Langley B.C

Posts: 2,619

|

SO WHATS THE PRICE

|

|

|

|

|

#8 |

|

Drives: G5.R Join Date: Sep 2010

Location: SoCal

Posts: 2,377

|

|

|

|

|

|

#9 |

Drives: '14 1LE, Z28.R Join Date: Apr 2014

Location: PA

Posts: 308

|

This is so tempting considering I live less than 2 hours from Penske...... So what's the price if I may ask?

|

|

|

|

|

#10 | ||

|

Drives: G5.R Join Date: Sep 2010

Location: SoCal

Posts: 2,377

|

Quote:

Quote:

There's post on here were folks who have broken parts on their Pfadt or Pedder’s sets. They are posting because they are looking to see if somebody will sell them their use ones since they can't get replacements so that they can get back on the road. Sounds like that turned out to be an expensive set if you asked me! Another great point plus if you’re so inclined, the fact you can build your own sets and learns the ins and out on how to service them, is another HUGE value. As you literally can be autonomous and service them yourself. If you need help, Penske is there to guide you This is TOTAL piece of mind. Last edited by Moreno1; 10-25-2014 at 09:58 PM. |

||

|

|

|

|

#11 |

Drives: '14 1LE Join Date: Nov 2013

Location: NJ

Posts: 2,435

|

Please PM price for the package - thanks!

|

|

|

|

|

#12 |

|

Casey Woodside

Drives: a very fun car Join Date: Jun 2010

Location: Tn

Posts: 1,906

|

send me a pm to please

__________________

Instagram @caseywoodside

http://youtu.be/CSc9aPh_X_w |

|

|

|

|

#13 |

Drives: 2013 Camaro 1LE Join Date: Jul 2012

Location: Verona, WI

Posts: 1,924

|

Hey Justin & Nathan,

While I'm not disputing Penske's reputation for quality shocks & struts, have they actually spent time doing R&D to find optimal damping rates/spring rates for the 5th Gen Camaro? GM designed the Camaro, had two track based performance packages under their belt (ZL1 and 1LE) and they still spent a year or more refining the damping rates/spring rates on the Z/28. So I would be hesitant to buy a Penske package that may not have had any R&D time devoted to refining the damping/spring rates for the 5th gen Camaro. As I said I am not disputing the fact that Penske builds a top notch product, but putting that top notch product into an application for which it was never designed/developed for doesn't mean you'll get optimal results. So if you have any other info you can share showing how Penske put some R&D time into developing this package specifically for the 5th gen to improve track handling then I think that would go a long ways towards selling this package to people. (unless I missed that part since your original post was pretty long and I may have skimmed over that part). Also with many of the other aftermarket choices we have had there have always been customer support contacts from these aftermarket choices (Pedder's, Pfadt, Ridetech,etc...) that provide buyers with guidance on best settings, alignments, etc... Does Penske have a person like this to help provide customer education and support if someone were to buy one of these strut packages from you? These are just a few of the questions/thoughts I had while reading over your very educational post on shocks/struts. I really do appreciate all the technical info you provided on shocks/struts as all that knowledge is obviously applicable regardless of the brand. But the brand name alone doesn't sell me on product. Regardless of brand I still want to see data showing that their product was truly design for my application. Thanks!

__________________

|

|

|

|

|

#14 |

|

141LE

Drives: 14 AGM 1LE Join Date: Oct 2013

Location: Springhill TN

Posts: 97

|

I'm also interested, please PM me details

__________________

|

|

|

|

|

|

|

|

|

|