You are browsing camaro5

|

|

|

#1 |

Drives: Camaro SS/RS inferno red interior Join Date: Mar 2012

Location: Pompano Beach FL

Posts: 817

|

Sub frame bushings South Florida

Does anyone and and could tell me the measurements on our sub frame bushings? Or if you are possible in south Florida and could possible let me borrow your stock ones so me and my guy can measure them. He makes sub frame bushings for BMW and he said he could make some for alot less but he would just need to see it in person (which would be better) or just get some measurements.

|

|

|

|

|

|

#2 |

|

Man I just had my subframe completely out of the car to replace mine. I wish I would have mic'd them. I bet some one can go out and measure them for you. Good luck

|

|

|

|

|

|

#3 |

Drives: Camaro SS/RS inferno red interior Join Date: Mar 2012

Location: Pompano Beach FL

Posts: 817

|

Ya i am hoping so haha but thanks anyway bro

|

|

|

|

|

|

#4 |

Drives: cars Join Date: May 2011

Location: Oversneeze

Posts: 4,542

|

Typically removal involves total destruction so unless someone has an uninstalled set of replacements...

But I wouldn't trust those measurements as gospel as the center ferule and dowel on the frame alter the bushing dimensions slightly when installed. Only pfadt's since aluminum won't be changing sizes. |

|

|

|

|

|

#5 |

|

Here are some basic measurements but if you PM me your address I'll send these old bushings to you.

|

|

|

|

|

|

#6 | |

|

Quote:

I wanted solid bushings but wouldn't spend the crazy money Pfadt want for theirs so I ended up with urethane. |

|

|

|

|

|

|

#7 |

|

|

|

|

|

|

|

#8 |

|

|

|

|

|

|

|

#9 |

Drives: cars Join Date: May 2011

Location: Oversneeze

Posts: 4,542

|

Word. We need details and you need a website guy.

|

|

|

|

|

|

#10 |

|

|

|

|

|

|

|

#11 |

|

Drives: Anything I want Join Date: Oct 2008

Location: DfW - Texas

Posts: 5,407

|

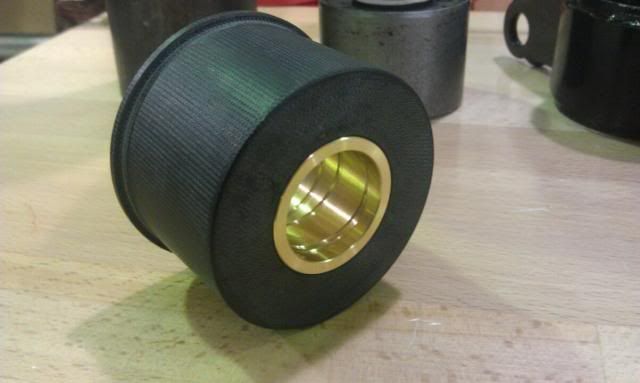

The Large machined aluminum parts are the subframe bushings prior to anodizing.

The other parts are the upper rear control arm mounts with stainless steel locators that are made of 3 precision machined materials(CARBON FIBER COMPOSITE,STAINLESS STEEL,BRONZE) for optimum strength and rigidity without the noise and vibration like other designs.

|

|

|

|

|

|

#12 |

|

Nice!!

|

|

|

|

|

|

#13 |

|

Drives: Camaro Justice Join Date: Jun 2007

Location: Virginia

Posts: 20,171

|

Interesting thread. Allow me to add some detail to it.

The benefits of solid sub-frame mounts and restrictive rear upper control arm mounts are frequently misinterpreted. We'll start with sub-frame bushes. These two videos shows the flex in an aftermarket set of sub-frame bushes. They movement is excessive leading one to believe that solid sub-frame mounts are a necessity. These are similar videos of Pedders EP1201HD sub-frame bushes with 568 FI RWHP in the first and over 600 NA RWHP in the second. In the second video Danny Popp is running a record time for the L/28 at Putnam park. The Pedders USA Camaro F/I 568 RWHP 305/30/19 RE-11 Danny Popp running at Putnam NA 600+ RWHP 305/35/20 ZL1 Spec Rubber Clearly the sub-frame is stable with Pedders EP1201HD sub-frame bushes installed. So why not just go to solid mounts? If you are building a racecar I would use Andy's solid mounts all day long. Drag cars run on controlled surfaces. Road course cars do the same. Rarely will you find a Grade 5 pot hole on any type of race track. You also don't find 6" concrete curbs - there maybe cement barriers, but never hard edged curbs. As solid as the EP1201HD appears to be in these videos, if you nail a severe pot hole or kiss a curb there is some deflection in the bush material that may limit impact damage to just the sub-frame and not carry sub-frame impact damage through to the monococque. The same is true with aftermarket arms. Adding a stronger arm to your street driven Camaro makes all the other components around it less strong in comparison. Working on a Challanger Texas Mile car we found the OEM cast iron toe link was literally bending the OEM mild steel bracket on the sub-frame. To control the toe to get the Challenger to track straight and true with over 900 foot pounds of torque we had to reinforce the OEM bracket.  How does that relate to a Camaro? We found the Challenger issue using a tire bar on the alignment rack to test for alignment changes under load. We could change toe in a 3 degree range. That is HUGE and VERY BAD. Following the Challenger we did similar testing with thee 5th Gen Camaro. Aside from the change in spec created from compression of factory bushings there was no change due to deflection. With Pedders bushings installed the change became insignificant. OEM arms are designed to be strong inline with loads as designed and to bend from a side load i.e. kissing a curb. The arm is sacrificed to protect the more expensive sub-frame. The upper outer rear control arm OE bushing is quite complaint. It needs to be as the upper control arm mounts to the knuckle with an enclosed monoball. The inner mount of the arm is also an enclosed monoball. The joint at the knuckle is parallel to the the ground allowing vertial and lateral motion. The inner joint in mounted vertically allowing the arm to rock up and down and side to side. Combine the shaft at the outer rear mouning position rotates in a circular motion. If the rear bushing doesn't allow the rear of the arm to follow the motion of the rest of the arm it creates a binding load some where is the arm. For a drag car that is a race car the additional stability of Andy's bush is desirable and the fatigue or wear factor insignificant. The drag racecar can make literally thousands of passes before the additional loads on the monoballs will cause significant wear or fatigue a portion of the arm. Those passes will be straighter and truer than the same passes with the OEM or Pedders bushings. In a road course car the same upper rear bushing will lead to rapid wear in the outer OEM monoball. We know. We have worn out too many parts in R & D and four years of OPTIMA with the 5th Gen. There is no free lunch. Decide what kind of Camaro you want to own and that will determine what mod path your should take. No one that reads my post should think that it is in any way intended to be disrespectful to Andy and his new products. They are obviously well engineered and made to his high standards. His parts are no different than my parts. They are tools and you should use the appropriate tool for the job at hand. |

|

|

|

|

|

#14 |

|

Drives: Anything I want Join Date: Oct 2008

Location: DfW - Texas

Posts: 5,407

|

Very nice write up

We have never built a 5TH GEN road race camaro and we have never done testing to the Extreme that LPE has done with the OPTIMA BATTERY CAR.This is not why I am on the forum,I am here to give the customer what they want.

When we first got started in the 5TH GEN CAMARO world we saw the need for good quality work as well as good quality parts,such as what I saw and learned while working up at Lingenfelter in the summer of 200? when John Lingenfelter was still overseeing every car that left the building.I learned that there is something required that only few in this industry have,that is the drive for perfection.With drive we found that things happen for a reason...Good people succeed,good product succeeds and buiness will run its course. My eyes were opened when that first camaro came in for a supercharger upgrade as well as a suspension upgrade to handle the new found power.At the time Pedders was unclear of when they would have product,But PFADT Racing was not.Pfadt stepped up to the plate offering lowering springs(always make a car look cool) as well as swaybars that when installed together made not only a good look but a much flatter (my words ) response . I was happy,the customer was happy......UNTIL!I say until because we had a problem with the swaybar bolts coming out and end link bolts coming out due to improper(in my opinion) slots in brackets,to thick flange ends on swaybars. The customer now had lost all confidence in my company as well as the product I represented.This was the first time in my 5TH GEN CAMARO career that I was unsure of what to do.I sat back and said nothing,I fixed the car as best as possible with new end links and New swaybar bolts with larer washers and red loctite.Problem Solved! Since then we have seen and installed every brand,every quality,every not so quality part made for the camaro ss.We have learned what works,what makes profit and what makes ADM SUCCEED!We choose our products wisely on a day to day basis,we are very hard to please.I saw the need to make adjustments to some produts that were currently selling,and not selling.I saw that ADM PERFORMANCE as a brand was known for quality,value and respected by this forum as a leader in this market.At this moment I realized it was no longer time to sit back and try,It was time for ADM PERFORMANCE to do something,we do something every day to make the camaro better,We do it with passion and we do it with a simple quote - "IS IT GOOD ENOUGH,THE CUSTOMER WILL DECIDE". Our product line is expanding at a rate even my web guy cant keep up with,we have so many irons in the fire it would make even the best say "WOW,HOW DO THEY DO ALL THAT".We will be offering new suspension parts,brake parts,supercharger parts,intake parts,carbonfiber parts,exhaust parts,turbo parts,nitrous parts and new tuning abilitys that have never even been thought of for the year 2013. So sit back and watch as we do what we do,we passion for the best. All ADM PERFORMANCE branded products are mae in the USA,By hard working Americans ..Not in China or any 3rd world country were labor is .02 an hr. |

|

|

|

|

|

|

|

|

|

|